A-7

INSTALLATION

Installation must be done by specialized technicians. Contact a certified electrician for set-up.

ATTENTION : Electrical supply installation must be in accordance with the electrical rating on the

nameplate.

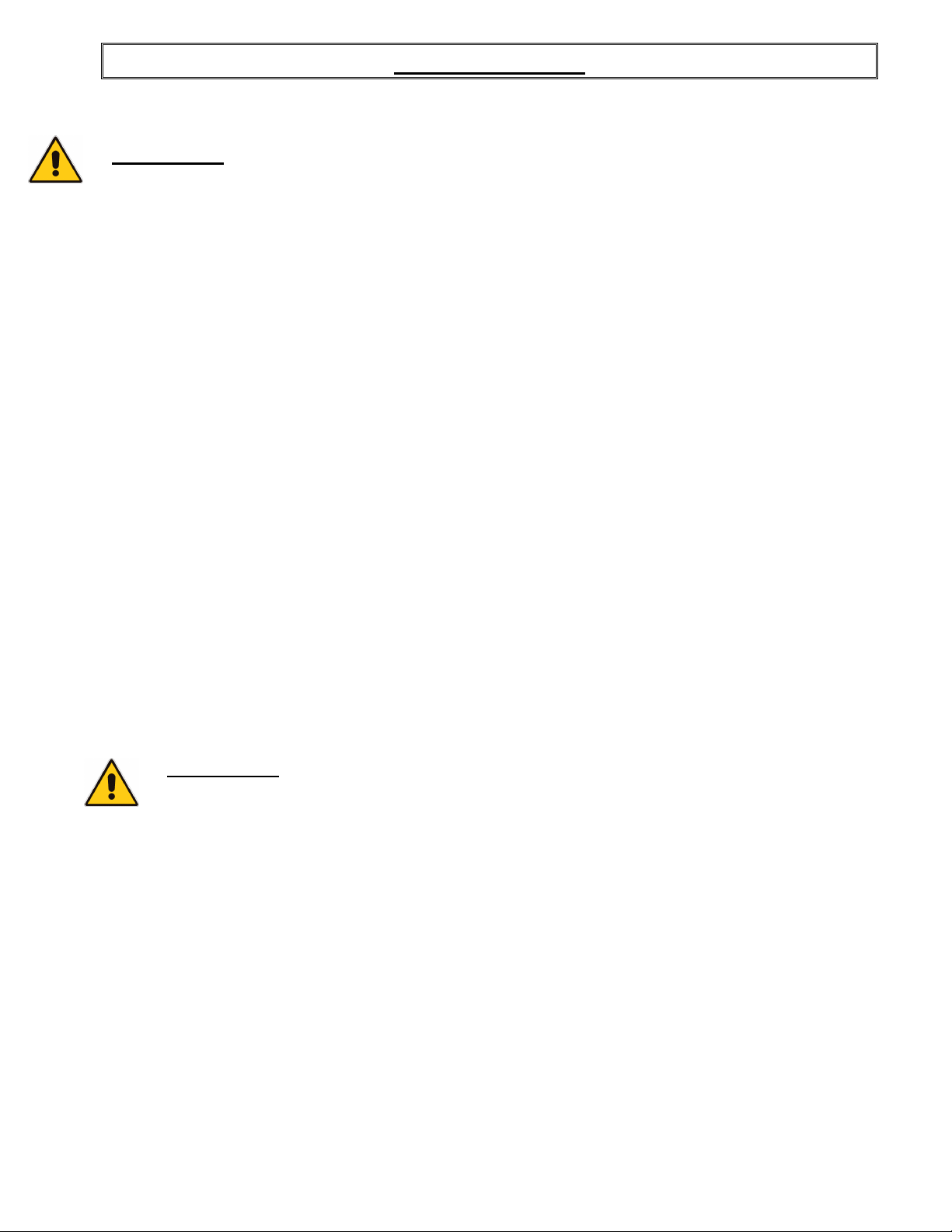

1. TROLLEY INSTALLATION

•Take out trolley’s components from the package, pay attention not to lose wheels and screws.

•Assemble the trolley, pay attention to the position of the two legs with inserts (see enclosures,

Fig. 17, n°1).

2. SHELVES INSTALLATION

•All trolleys are predisposed to be assembled with two shelves (optional).

•Take out the shelves components from the package, pay attention not to lose screws.

•Assemble shelves by using the proper screws and nuts (Fig. 18).

•Shelf in open position, fasten the nuts as in Fig. 19.

•Shelf in closed position, fasten the nuts as in Fig. 20.

3. DIVIDER DD10 INSTALLATION

•Assemble the components that are in the tank as follow :

•MACHINE FOR BENCH:

-Assemble the four legs, the chute and the door for the pasta’s outlet (Fig. 14).

ATTENTION : The chute and the door for the pasta’s outlet are safety devices provided

with a sensor. If there aren’t these devices or they are badly installed the machine can’t work.

•MACHINE WITH ROUNDER

-Fix the machine to the trolley by using the four proper screws (Fig. 15).

-Assemble the funnel (Fig. 16)