Table of Contents

INTRODUCTION ...................................................................................................................................... 3

ATTENTION.......................................................................................................................................... 3

CONSTRUCTION...................................................................................................................................... 3

SHIPPING................................................................................................................................................... 3

IMPORTANT-RECEPTION OF THE MERCHANDISE ..................................................................... 3

INSTALLATION ....................................................................................................................................... 4

IMPORTANT INSTALLATION AND SERVICE................................................................................ 4

FOR YOUR SAFETY............................................................................................................................. 4

IN GENERAL ..................................................................................................................................... 4

INSTALLERS......................................................................................................................................... 4

TO THE ELECTRICIAN.................................................................................................................... 4

TO THE PLUMBER ........................................................................................................................... 4

DISTANCES TO RESPECT .................................................................................................................. 4

ASSEMBLY............................................................................................................................................... 5

Foreword ................................................................................................................................................. 5

TOOLS REQUIRED............................................................................................................................... 5

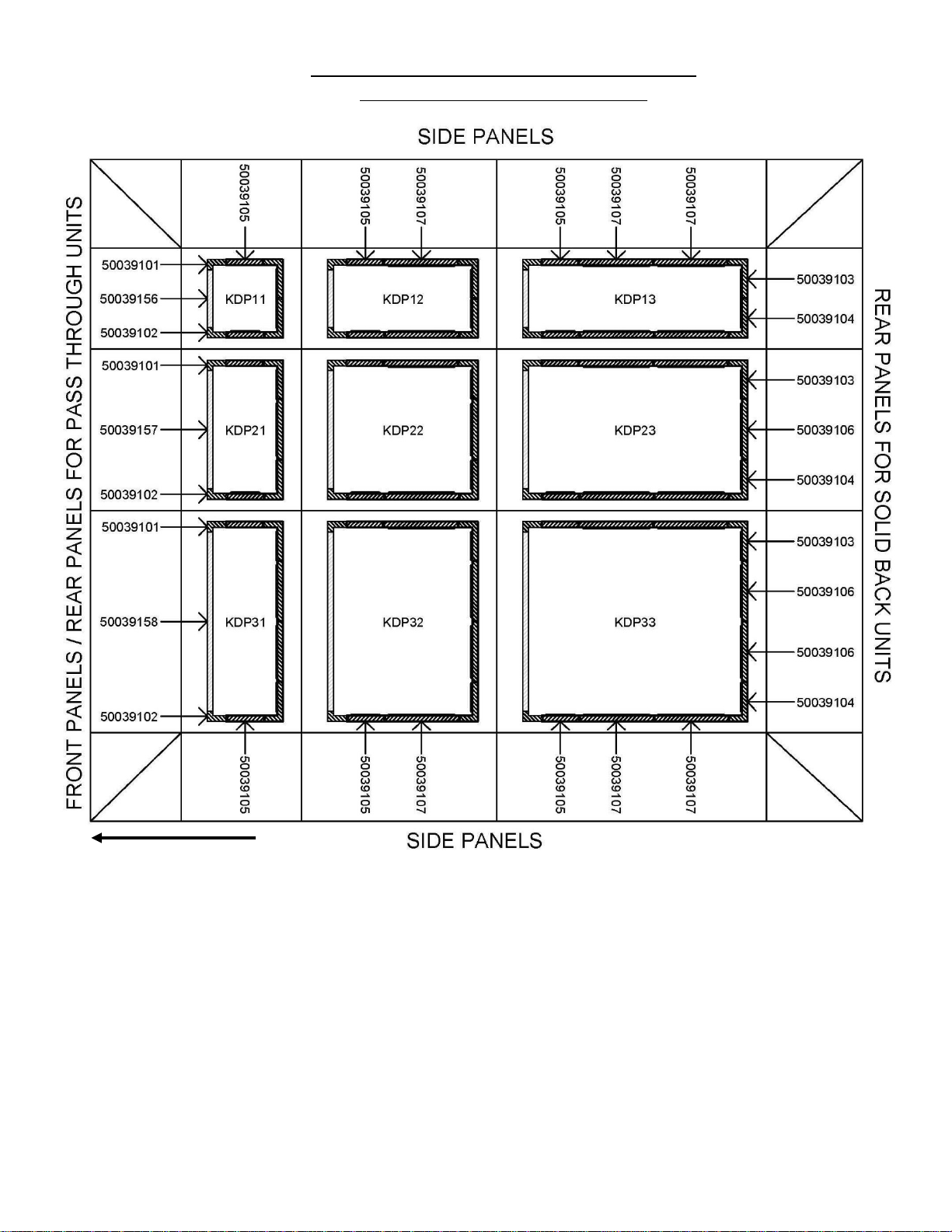

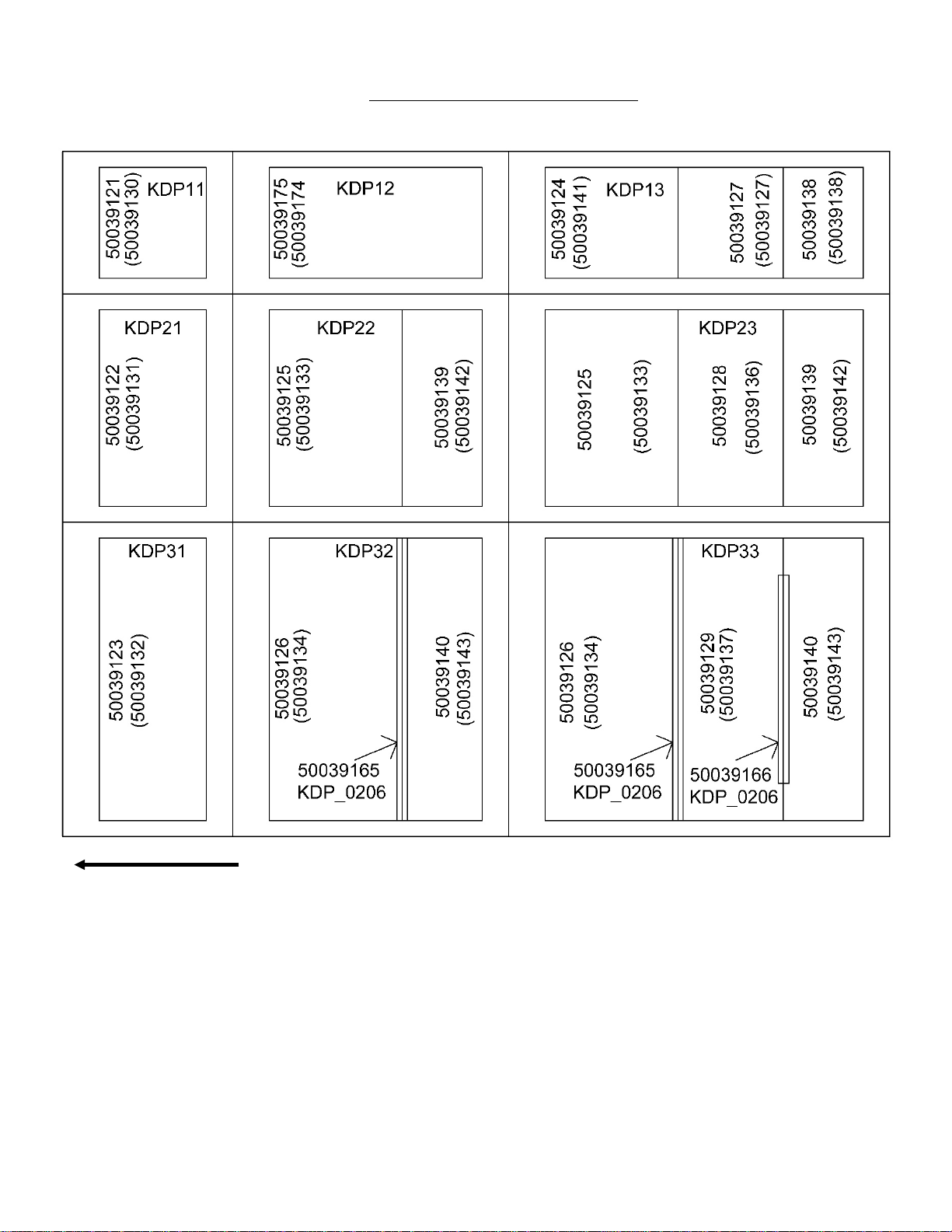

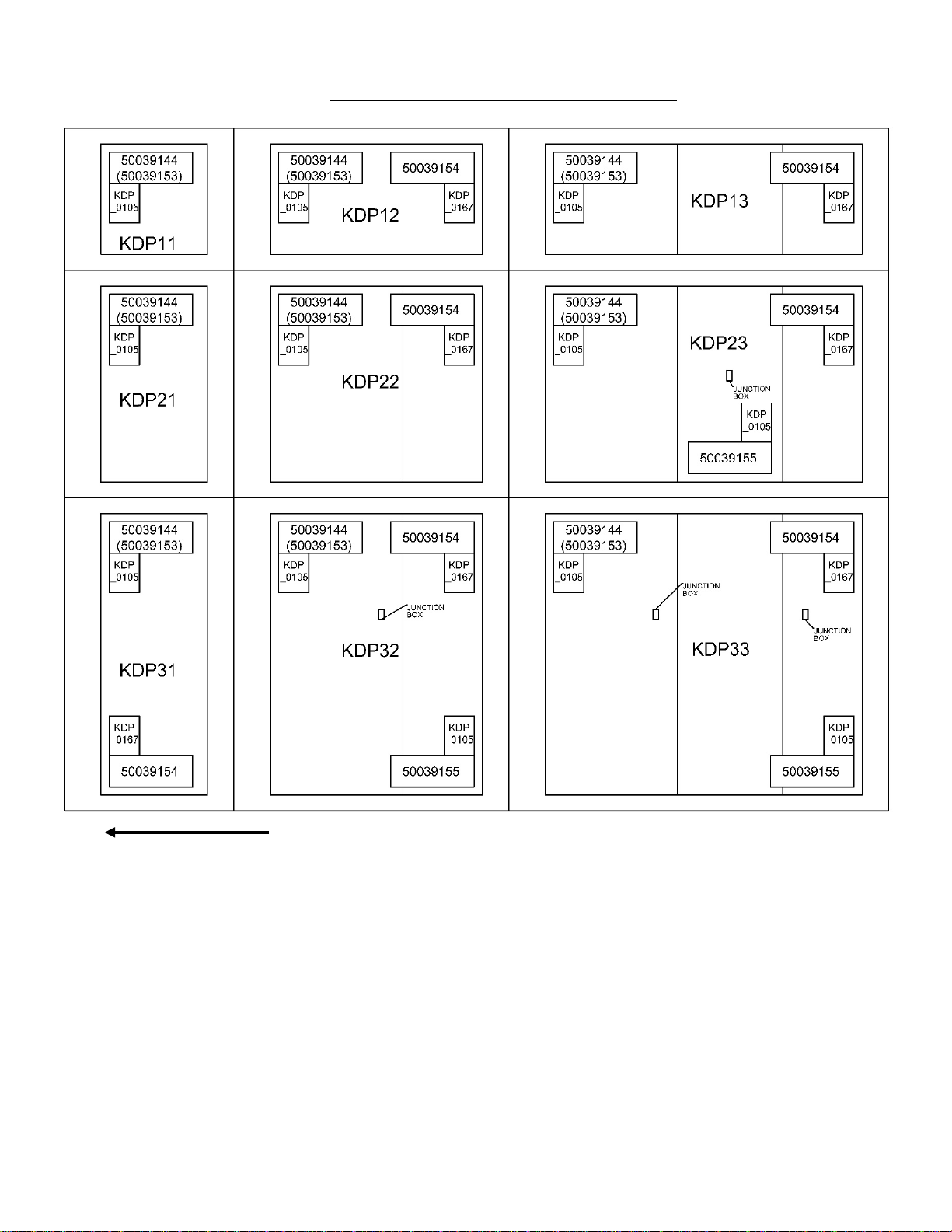

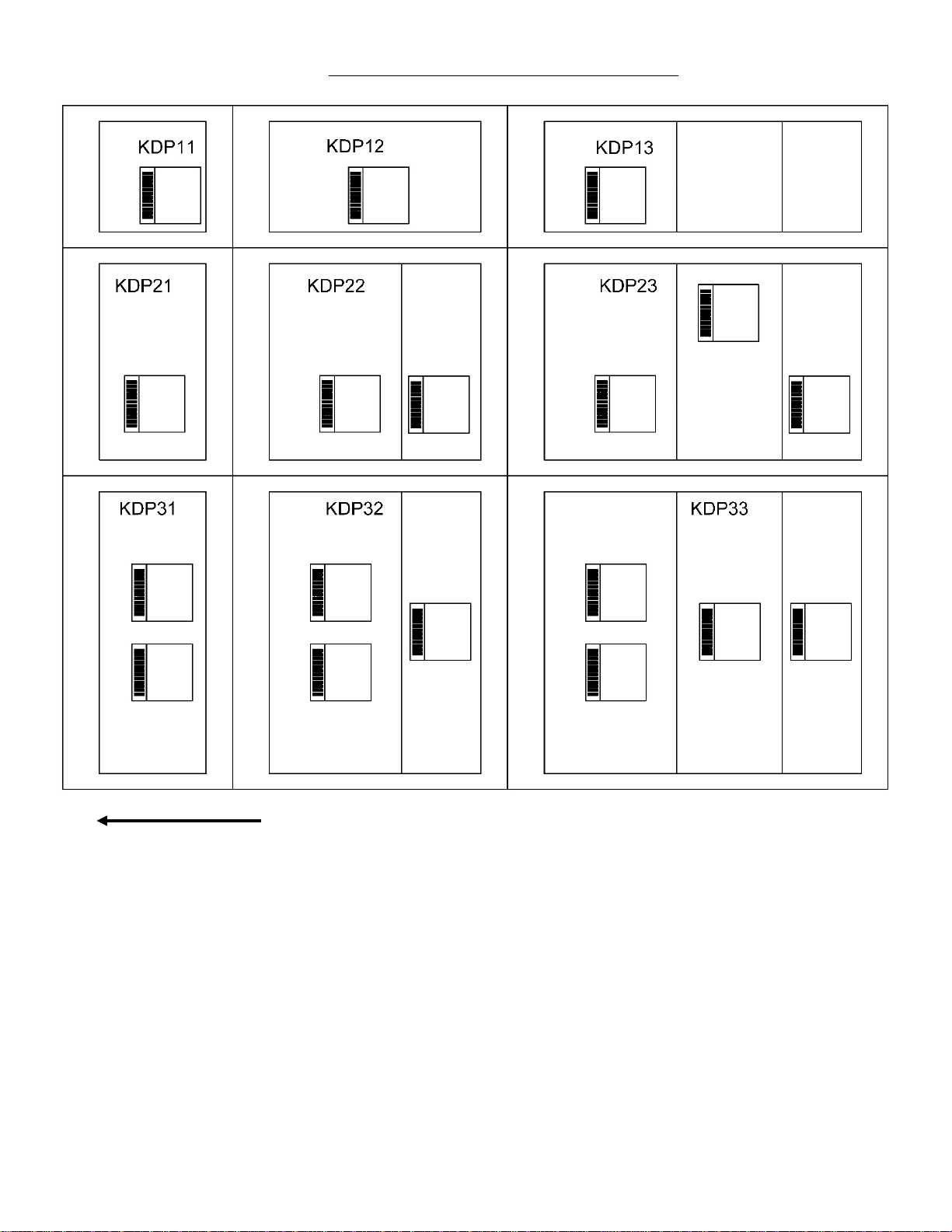

KDP SERIES CONFIGURATION DIAGRAMS .................................................................................. 6

WALL PANEL CONFIGURATIONS................................................................................................ 6

TOP PANEL CONFIGURATIONS.................................................................................................... 7

ELECTRICAL PANEL CONFIGURATIONS................................................................................... 8

REFRIGERATION MODULE PLACEMENT .................................................................................. 9

ERECTING WALLS (NON-PASS THRU UNIT)............................................................................... 10

ERECTING WALLS (PASS THRU UNIT)......................................................................................... 11

INSTALLING TOPS ............................................................................................................................ 12

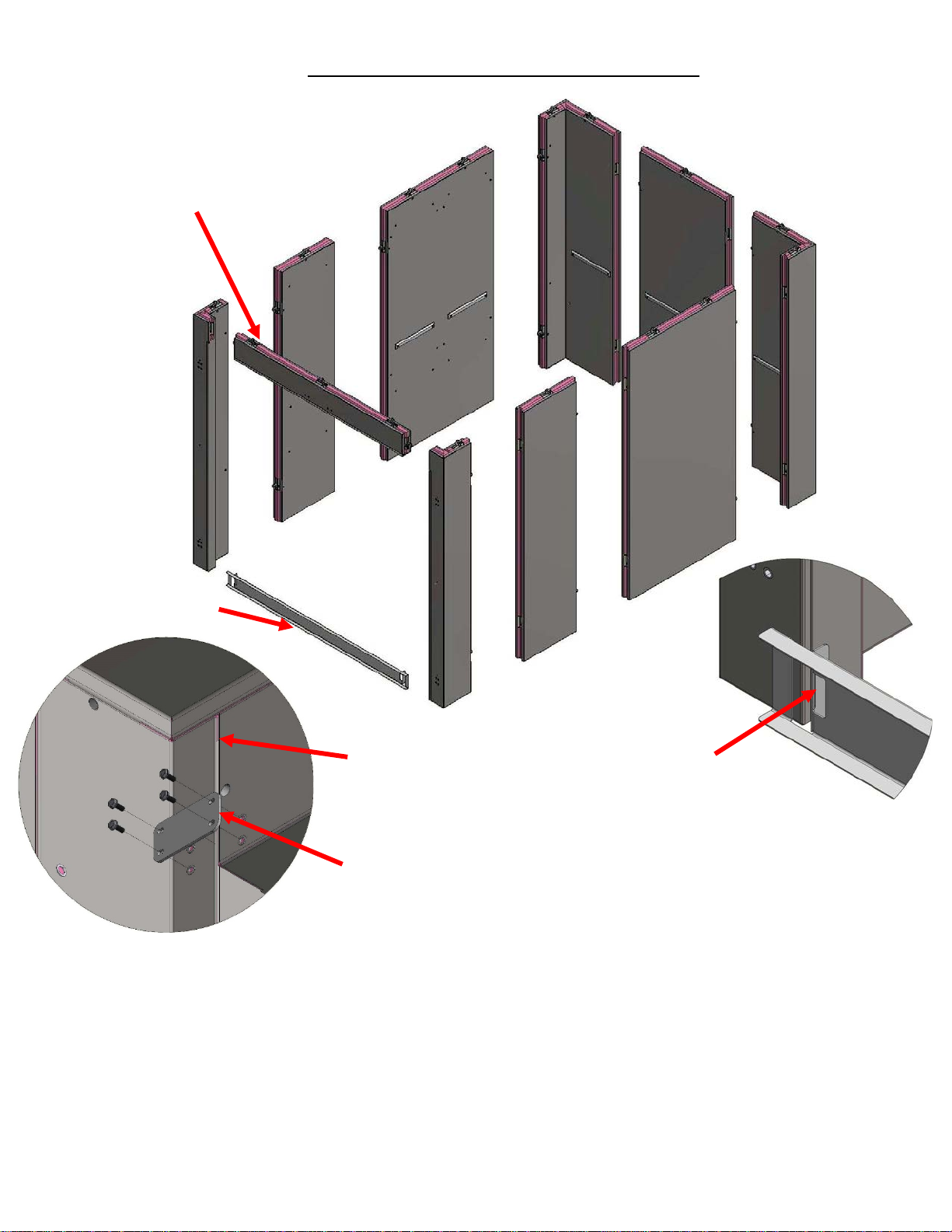

INSTALLING CORNER BRACKETS................................................................................................ 13

INSTALLING ELECTRICAL PANEL................................................................................................ 14

INSTALLING REFRIGERATION MODULES (RETARDER MODELS)........................................ 15

INSTALLING WATER BOX .............................................................................................................. 16

PLUMBING (ONLY ON KDPR MODELS) ....................................................................................... 17

INSTALLING HEATER ASSEMBLIES............................................................................................. 18

INSTALLING HEATER ASSEMBLIES CONT................................................................................. 19

INSTALLING PROBES....................................................................................................................... 20

INSTALLING FANS............................................................................................................................ 21

INSTALLING FANS CONT................................................................................................................ 22

INSTALL WATER PAN AND ELEMENT......................................................................................... 23

INSTALLING DOOR GASKET(S)..................................................................................................... 24

INSTALLING DOOR(S)...................................................................................................................... 25

INSTALLING FACADES.................................................................................................................... 26

FINAL INSPECTION .............................................................................................................................. 27

OPERATION OF THE PROOFER.......................................................................................................... 28

PROOFER MODE................................................................................................................................ 29

RETARDING MODE........................................................................................................................... 30

AUTOMATIC PROOFING/RETARDING MODE SET UP............................................................... 31

REAL TIME CLOCK SETUP.............................................................................................................. 32

MAINTENANCE AND CLEANING...................................................................................................... 33