2

DOYON ARTISAN OVEN

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

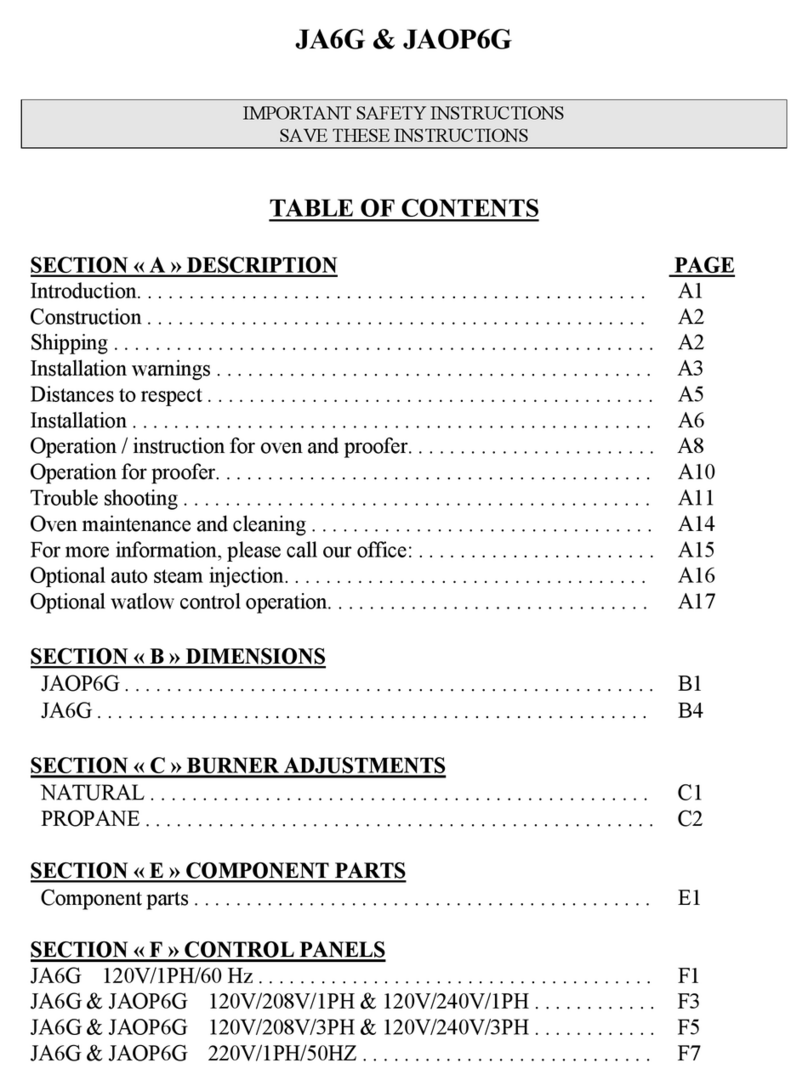

TABLE OF CONTENTS

TO GET THE BEST PERFORMANCE OF YOUR MACHINE, READ

CAREFULLY THIS MANUAL.

1. SHIPPING...................................................................................................................... 3

2.RECEPTION OF THE MARCHANDISE .................................................................. 3

3. INSTALLATION .......................................................................................................... 4

3.1. DISTANCES TO RESPECT ...................................................................................4

3.2. IN GENERAL .......................................................................................................... 5

3.3. TO THE ELECTRICIAN......................................................................................... 5

3.4. TO THE PLUMBER................................................................................................5

4. INTRODUCTION......................................................................................................... 6

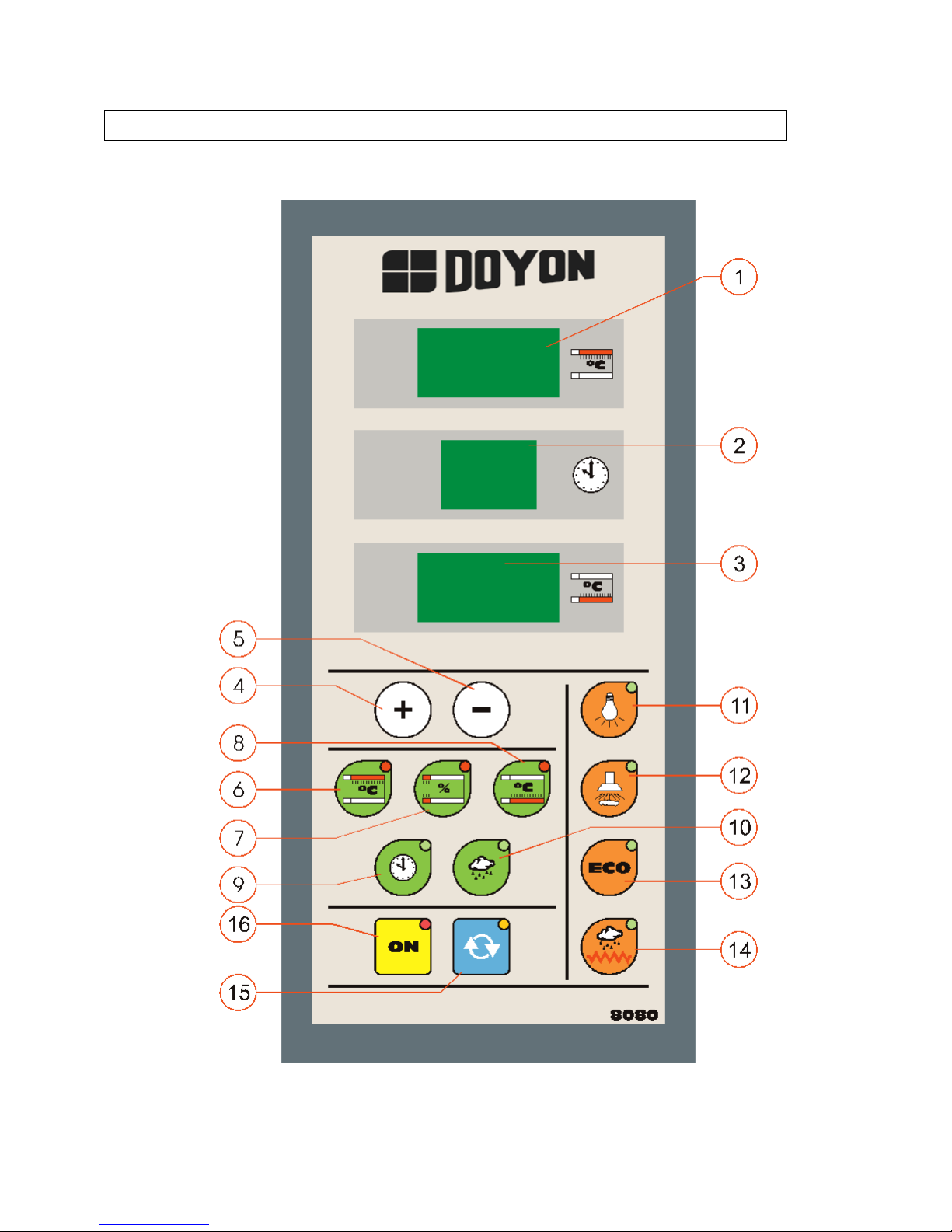

5. DESCRIPTION OF THE CONTROL........................................................................ 7

6. CONTROL OPERATION ......................................................................................... 10

6.1. TEMPERATURE ADJUSTMENT........................................................................ 10

6.2. SETTING POWER OF THE FRONT, TOP AND BOTTOM .............................. 10

6.3. SETTING TIMES .................................................................................................. 10

6.4. DISPLAY UNITS .................................................................................................. 10

7. WARNING MESSAGES............................................................................................ 11

7.1. OPENING MESSAGE........................................................................................... 11

7.2. COLD VAPOR MESSAGE................................................................................... 11

7.3. END OF COOKING .............................................................................................. 11

7.4. BREAKDOWN MESSAGES ................................................................................ 11

8. FIRST TIME HEATING THE OVEN...................................................................... 13

9. BAKING....................................................................................................................... 13

10. TROUBLESHOOTING............................................................................................ 14

11. OVEN MAINTENANCE AND CLEANING ......................................................... 15

COMPONENT PARTS .................................................................................................. 17