476 Issue date: 17 November 2006 9 of 80

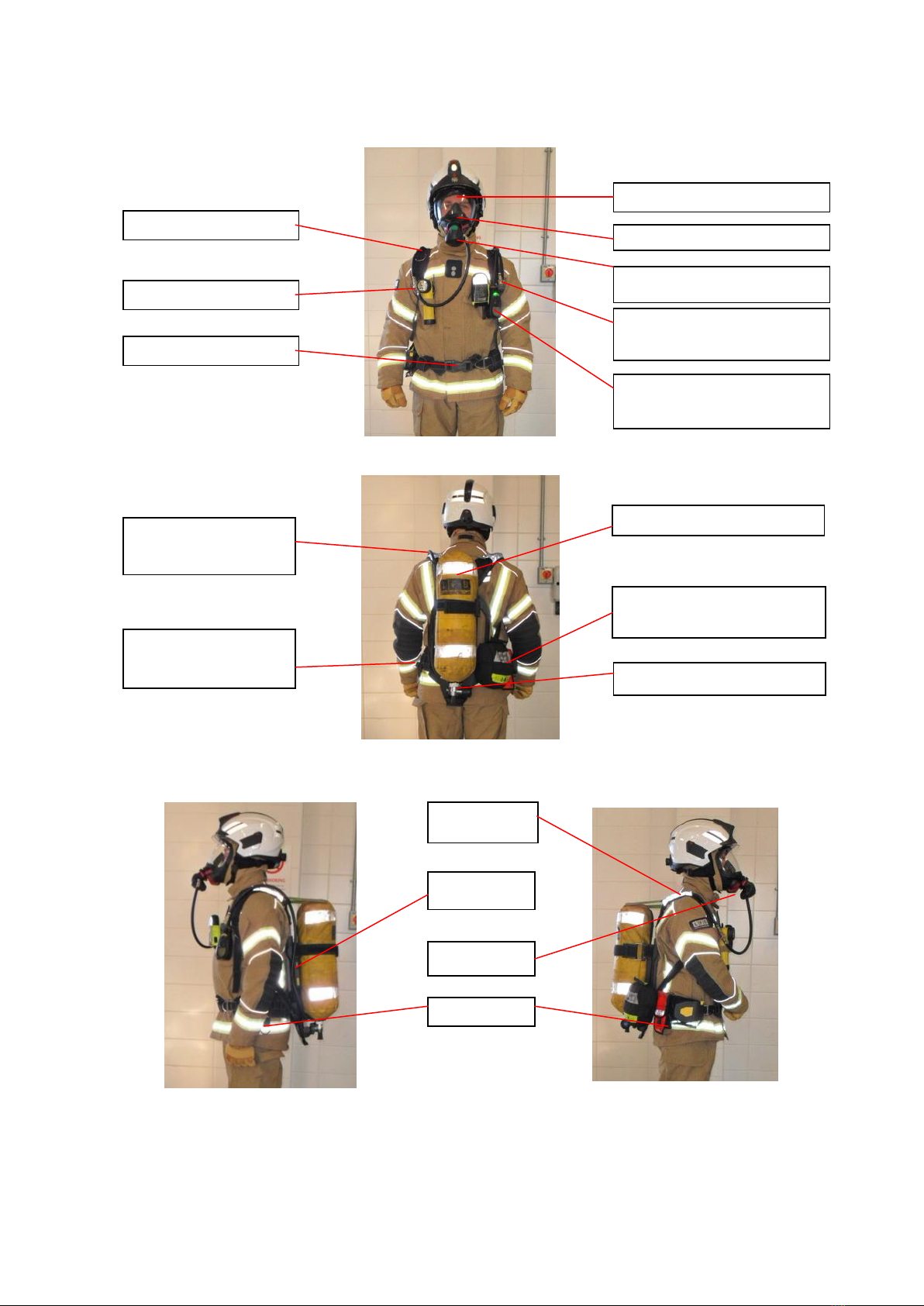

3Backplate assembly

General

3.1 The height adjustable, and articulating backplate assembly, provides the wearer maximum

comfort and ease of use, resulting in reduced wearer fatigue. The backplate assembly consists of

three elements:

1. The adjustable shoulder yoke.

2. The backplate.

3. The waist belt pivot slide assembly.

3.2 Each of the elements is manufactured from a moulded

carbon composite material, providing an anti-static,

lightweight and durable system.

3.3 The adjustable shoulder yoke has two guide arms that

locate, and slide, in the two channel slots in the rear of

the backplate.

3.4 At the base of the backplate is the waist pivot slide

assembly. This unit is assembled to a spring loaded

vertical slide that is guided in a vertical slot in the

backplate.

3.5 Two compression springs, in the slide assembly, act against the slide and pivot slide assembly to

hold the unit at the top of the slide.

3.6 When wearing the BA set, the waist pivot slide assembly slides, and pivots, in response to the

twisting and bending movements of the upper body of the wearer. This flexibility improves the

weight distribution, and provides freedom of movement and increased manoeuvrability for the

wearer.

3.7 For maximum comfort and improved weight distribution adjust the

shoulder straps to allow the BA set waist belt to be positioned

comfortably on the hips so that weight is taken through legs.

3.8 A twin hook arrangement, moulded at the base of the SDBA backplate,

provides a positive mounting for the body of the pressure reducer.

3.9 Located in the recess behind the twin hook is a pre-loaded coiled return

spring. The spring latches onto an extended portion (lug) on the body

of the pressure reducer, securing the reducer assembly in its twin hook

location.

3.10 A degree of pivotal movement of the reducer is possible to allow for the

alignment of the hand wheel of the reducer to the cylinder valve.

3.11 The EDBA reducer is not mounted to the backplate.

3.12 A rubber shock buffer, at the base of the backplate, provides additional

impact protection.

3.13 Side handles, incorporated into the backplate moulding, allow for the

BA set to be easily carried (without cylinder attached).