3367233 (A3-D-P) Page 2 of 4

4 Use

WARNING

Only trained and competent users are permitted to prepare and use this

equipment.

►Ensure that any accessories, ancillary equipment, and other

protective clothing items do not interfere with the breathing apparatus

and do not create a safety hazard.

The effective working duration of the apparatus depends on the initial air

supply available and the breathing rate of the wearer.

►Fill compressed air cylinders to their full rated pressure before use.

►Do not commence any operation (including supplied-air respirator

(SAR) operations) using a cylinder that is less than 90 percent full.

CAUTION

Equipment damage may cause the release of high-pressure air.

►Do not apply excessive force or use tools to open or close a cylinder

valve.

►Do not drop or throw down the breathing apparatus.

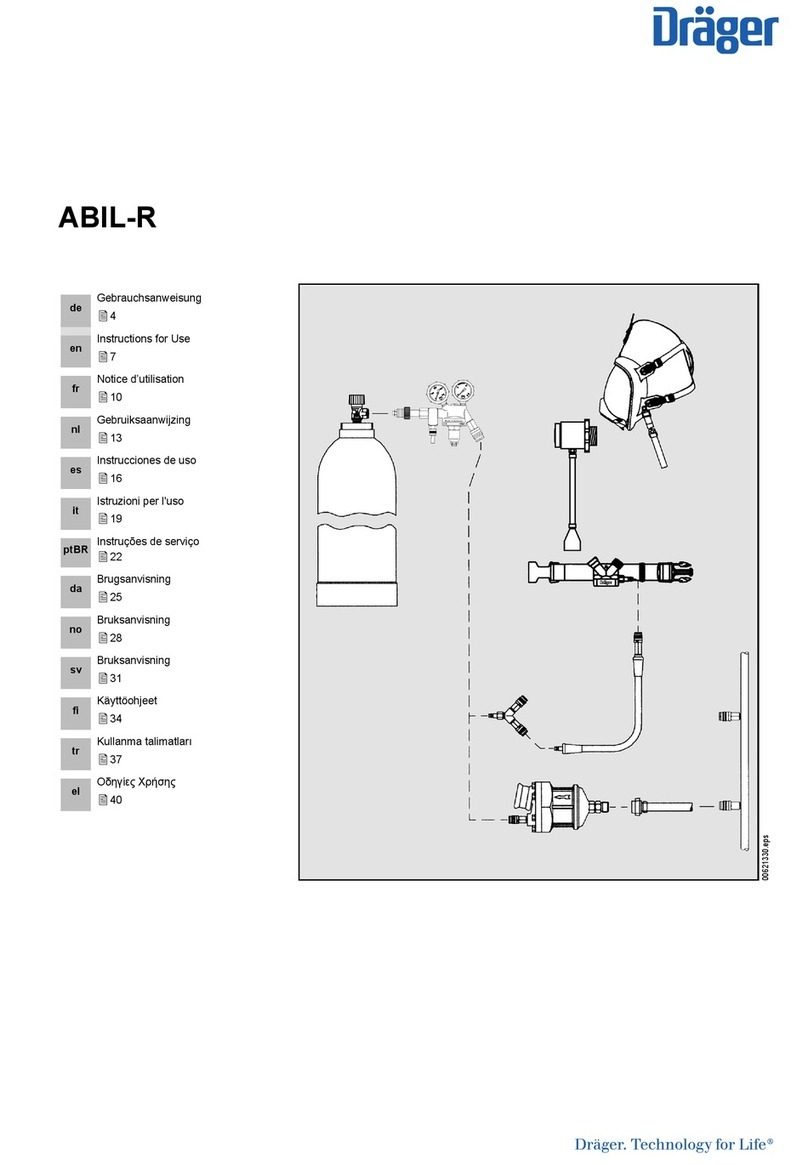

4.1 Prerequisites

Refer to the following additional information before preparing or using the

breathing apparatus:

●The special instructions (see Section 11).

●For non-CBRN use, see the separate NIOSH approval table 3367123

for approved configurations.

●For CBRN use, see the separate NIOSH CBRN approval table

3367124 for approved configurations. For CBRN use, the user must

also refer to the CBRN special instructions in the lung demand valve

instructions for use.

The TX Gauge battery cover and batteries are supplied unfitted. Install the

batteries and fit the battery cover before use (see Section 4.6.3).

4.2 Preparation for use

Replace the batteries if the device fails to operate, or if a low battery alarm

activates.

1. Carry out a visual inspection of the apparatus (see Section 4.6.1).

2. Install the TX Gauge batteries if necessary (see Section 4.6.3).

3. Fit the compressed air cylinder (see Section 4.6.4).

4. Adjust the backplate height to the position required by the wearer (see

Section 4.6.2)

5. Press the male coupling of the lung demand valve hose into the female

coupling of the medium-pressure hose until an audible click is heard

(do not connect the valve to the face mask at this stage).

6. Press the reset button (Fig C, Item 1) to switch off the positive

pressure. Press and rotate the bypass button (Fig C, Item 3) to align

the red spots and then release the button to switch off the bypass.

7. Pair the TX Gauge with one or more compatible PASS devices if

necessary (see the PASS device instructions for use).

8. Carry out a full functional test of the apparatus (see Section 4.6.5).

9. Align and push the lung demand valve into face mask port until it

latches in position, and check the attachment by gently attempting to

pull the coupling apart.

4.3 Putting on the breathing apparatus

1. Fully loosen the shoulder harness and waist belt and put on the

breathing apparatus.

2. Check that the shoulder pads are not twisted and take the weight of the

system on the shoulders by pulling the shoulder harness. Do not fully

tighten at this stage.

3. Close the waist belt buckle and pull the ends of the waist belt forward

until the strap padding fits securely and comfortably over the hips

(Fig D). Tuck the belt ends behind the waist pad.

4. Pull the shoulder harness until the breathing apparatus rests securely

and comfortably on the hips. Do not over tighten. Pull the strap

retainers down to secure the strap ends (Fig E).

5. Fully loosen the head straps of the face mask and place the neck strap

over the back of the neck.

6. Press the reset button (Fig C, Item 1) to switch off the positive

pressure.

7. Open the cylinder valve (counterclockwise) slowly, but fully, to

pressurize system. TX Gauge automatically switches on and performs

a self-test.

○If the self-test passes, the green LED will flash once every second

to indicate that the TX Gauge is switched on.

○If the self-test fails, the amber LED will flash once every 2 seconds

for 10 seconds. Report the fault to trained service personnel. Do

not use the breathing apparatus until the fault condition is rectified.

●After storage at temperatures below 32 °F (0 °C) leakage may be

observed when the cylinder valve is initially opened due to ice

formation.

○If leakage is observed from the lung demand valve, press the front

button (Fig C, Item 2) to allow a rush of air to pass through the lung

demand valve and then quickly press the reset button (Fig C,

Item 1) to switch off the positive pressure. Resume normal

operation.

○If leakage is observed from the quick connect coupling, close the

cylinder valve and vent the system. Disconnect then reconnect the

cylinder to the breathing apparatus (see the quick connect

coupling instructions for use), then reopen the cylinder valve

slowly, but fully, to pressurize the system. Resume normal

operation.

○If leakage still occurs, remove the breathing apparatus from

service and report the fault to trained service personnel or contact

Dräger.

WARNING

If there is not a good seal between the mask and the face of the wearer,

the mask may leak inward or outward during use.

►In a CBRN environment, use only face mask sizes that have been

confirmed by a quantitative fit test (QNFT).

8. Put on the face mask and check the seal between the mask and face

of the wearer (for non-CBRN use see the Dräger FPS®7000 face

mask instructions for use; for CBRN use see the CBRN special

instructions in the lung demand valve instructions for use).

4.4 During use

WARNING

Users should be in a safe area before the whistle or end-of-service-time

warnings commence.

►Fully open all cylinder valves and ensure that they remain open during

use.

►Evacuate to a safe area immediately if warnings commence during an

operation.

●Regularly check the remaining cylinder pressure on the gauge.

●Press the illumination button (Fig B, Item 1) to illuminate the gauge

face.

●React to the following alarm and warning signals as necessary:

○EOSTI – The mechanical warning whistle in the TX Gauge

sounds, and the red LED flashes. The warning whistle and red

LED will activate within the preset pressure range (see EOSTI

Alarms in Section 10). Due to the activation tolerance, they may

not activate at exactly the same time. The red LED will switch off

when the pressure in the compressed air cylinder drops below

116 psi. The warning whistle will continue to sound until the

compressed air cylinder pressure reaches zero.

○Low battery – The amber LED (Fig B, Item 2) will flash once every

5 seconds.

WARNING

Using the bypass button (Fig C, Item 3) uses air from the cylinder and may

rapidly reduce the working duration of the apparatus.

►Do not use the bypass button unless absolutely necessary.

●If additional air is required, briefly press and release the bypass

button (Fig C, Item 3) to deliver a single jet of air into the face mask.

WARNING

The following emergency air flow procedures may greatly reduce the

operating duration of the air supply.

►When activated the user must immediately evacuate to a safe area.

►The reason for using the procedure must be investigated and repaired

before reusing the breathing apparatus.

●Additional air flow required (emergency procedure only used in the

unlikely condition of low or blocked airflow) – Press and rotate the

bypass button (Fig C, Item 3) to deliver a sustained air supply (85 to

130 liters/minute) into the face mask.

●Excessive or loss of air flow (emergency procedure only used in the

unlikely condition of high or loss of airflow) – Close the cylinder valve

then immediately begin to slowly reopen the valve. Use the cylinder

valve as a regulating valve to set the air flow to meet the user

requirement. This procedure can be used with screw-type and ratchet-

type cylinder valves.

4.4.1 Sentinel TX Gauge visual signals

The visual signals provided by the TX Gauge are shown in the following

table.

4.5 After use

WARNING

Removing the breathing apparatus in a hazardous breathing environment

is unsafe.

►Do not remove the breathing apparatus until in a safe breathing

environment.

NOTICE

The equipment can be damaged if removed incorrectly.

►Do not remove the face mask by pulling on the lung demand valve.

1. Loosen the face mask straps. At the point when the seal between the

face mask and the face is broken, press the reset button (Fig C,

Item 1) to switch off the positive pressure. Fully remove the face mask

and extend all the straps of the head harness.

2. Close the cylinder valve.

3. Press the front button (Fig C, Item 2) to vent system and then press the

reset button (Fig C, Item 1) to switch off the positive pressure. The

TX Gauge will switch off automatically when the pressure drops below

116 psi. As the TX Gauge switches off, it transmits a signal. Paired

devices that receive the signal will either switch off or indicate that they

have logged off from the breathing apparatus (see the device

instructions for use).

4. Release the waist belt buckle (Fig F or Fig G).

5. Lift the shoulder harness ends to release the strap retainers (Fig E)

and then lift the shoulder harness buckles to loosen the straps.

6. Remove the breathing apparatus and face mask.

7. If the lung demand valve has been set to bypass, press and rotate the

bypass button (Fig C, Item 3) to align the red spots and then release

to switch off the bypass.

8. Carry out the after use tasks in the maintenance table (see

Section 6.1).

9. Remove the compressed air cylinder if necessary (see Section 4.6.4).

10. Pass the breathing apparatus to the service department with details of

any faults or damage that occurred during use.

Visual signal Explanation

Flashing green LED TX Gauge is switched on

Flashing red LED Low cylinder pressure

Flashing amber LED once every

5 seconds

Low battery

Flashing amber LED at 2 second

intervals for 10 seconds

Failed self check or hardware fault

Solid green LED Attempting to establish communication

with Dräger PC Link

Flashing green and amber LEDs Communicating with Dräger PC Link

Solid green and white LEDs; flashing red

LED

Attempting to pair with a PASS device

Alternating flashing white and green/

amber LEDs

Successfully paired with a PASS device

Alternating flashing red and amber LEDs Unable to pair with a PASS device

4.6 Common user tasks

4.6.1 Visual inspection

A visual inspection must check the full breathing apparatus including all

component parts and accessories. Check that the equipment is clean and

undamaged, paying particular attention to pneumatic system components,

hoses, and connectors. Typical signs of damage that may affect the

operation of the breathing apparatus include impact, abrasion, cutting,

corrosion, and discoloration. Report damage to service personnel and do

not use the apparatus until faults are rectified.

4.6.2 Adjusting the backplate height

1. Lift the apparatus into the vertical position.

2. Simultaneously press the two spring-loaded buttons (Fig H) to unlock

the shoulder yoke. Slide the yoke in the required direction then release

the buttons. Continue sliding the yoke until the buttons engage and

lock the yoke in the required position.

4.6.3 Fitting or replacing the batteries

WARNING

Improper handling and use of batteries may cause an explosion, a fire, or

a chemical hazard.

►Do not remove or install the batteries in a flammable atmosphere.

►Do not expose the batteries to heat sources.

►Do not attempt to recharge any non-rechargeable battery.

►Do not short out the battery terminals.

►Use only the recommended battery type.

►Replace batteries as a matched set and do not mix new and used

batteries.

NOTICE

Batteries that are not correctly disposed of may cause an environmental

hazard.

►Dispose of used batteries in accordance with national or local

regulations.

●The normal operating life of the batteries depends on operating time,

frequency of alarms and ambient temperature.

●Remove discharged batteries from the product.

●To preserve the datalog clock, install new batteries within 3 minutes of

removing the discharged batteries.

●Use only the following approved battery type: Panasonic®CR123AL/

1BP (3 V).

1. Remove the four screws using a 2.5 mm hexagon key, and remove the

battery cover (Fig L).

2. Remove the discharged batteries and install a new set observing the

polarity marked inside the battery compartment.

3. Check the cover and sealing ring. Lightly coat the sealing ring with

Dow Corning®Molykote®111 silicone grease (as a guideline, the

grease should be felt on the fingers but not seen).

4. Refit the battery cover and screws. Do not over tighten the

screws: Dräger recommend torque of 0.5 lbf ft (0.7 Nm).

4.6.4 Fitting or removing the compressed air cylinder

WARNING

High-pressure air release may cause injury to the user or other personnel

near the breathing apparatus.

►Close the cylinder valve and fully vent the system before attempting to

disconnect an compressed air cylinder.

Impact damage to the cylinder valve or first-stage regulator connector may

prevent valve connection or cause an air leak.

►Handle the compressed air cylinder and breathing apparatus with

care.

The following instructions are for a threaded cylinder coupling. See the

quick connect coupling instructions for use for details of fitting and

removing a quick connect coupling.

Fitting the cylinder

1. Set the backplate to position S.

2. Check the threads of the cylinder valve port and the first-stage

regulator. Ensure that the O-ring seal (Fig I, Item 1) in the first-stage

regulator is clean and undamaged.

3. Lay the backplate horizontal, with the first-stage regulator uppermost,

and fully extend the cylinder strap.

4. Insert the cylinder through the loop of the strap, and align the valve with

the regulator.

5. Lift the cylinder and backplate into the vertical position (supported on

the end of the cylinder opposite the valve).

6. Tighten the hand wheel of the regulator, using only the thumb and

index finger, until a definite metal-to-metal contact is felt. Do not use

tools or over tighten.

7. Place the unit back into the horizontal position.

8. Take up the slack in the cylinder strap (Fig J).

9. Pull the strap over the cylinder to operate the cam-lock buckle (Fig K)

and secure using the hook-and-loop fastener.

Removing the cylinder

1. Close the cylinder valve and press the front button (Fig C, Item 2) to

fully vent the system.

2. Set the backplate to position S.

3. Lay the backplate horizontal, with the cylinder uppermost.

4. Remove the free end of the cylinder strap from the hook-and-loop

fastener.

5. Lift the strap against the cam-lock buckle to release the buckle tension

and loosen the strap.

6. Disconnect the cylinder valve from the first-stage regulator.

7. Lift the cylinder away from the first-stage regulator and remove the

cylinder.

4.6.5 Functional testing

WARNING

Failure of the equipment to meet any of the standards or parameters in the

functional test, or any visible signs of damage, indicates a possible system

fault.

►Do not use the equipment and report the fault to trained maintenance

personnel or contact Dräger.