4Dräger SAM 3100/3200

For your safety

1 For your safety

1.1 General safety notes

Before using this product, carefully read the Instructions

for Use.

Strictly follow the Instructions for Use. The user must fully

understand and strictly observe the instructions. Use the

product only for the purposes specified in the Intended use

section of this document.

Do not dispose of the Instructions for Use. Ensure that they

are retained and appropriately used by the product user.

Only trained and competent users are permitted to use

this product.

Comply with all local and national rules and regulations

associated with this product.

Only trained and competent personnel are permitted to

inspect, repair and service the product as detailed in these

Instructions for Use (see section 6 on page 8). Further

maintenance work that is not detailed in these Instructions

for Use may only be carried out by Dräger or personnel

qualified by Dräger. Dräger recommends a Dräger service

contract for all maintenance activities.

Use only genuine Dräger spare parts and accessories,

or the proper functioning of the product may be impaired.

Do not use a faulty or incomplete product. Do not modify

the product.

Notify Dräger in the event of any component fault or failure.

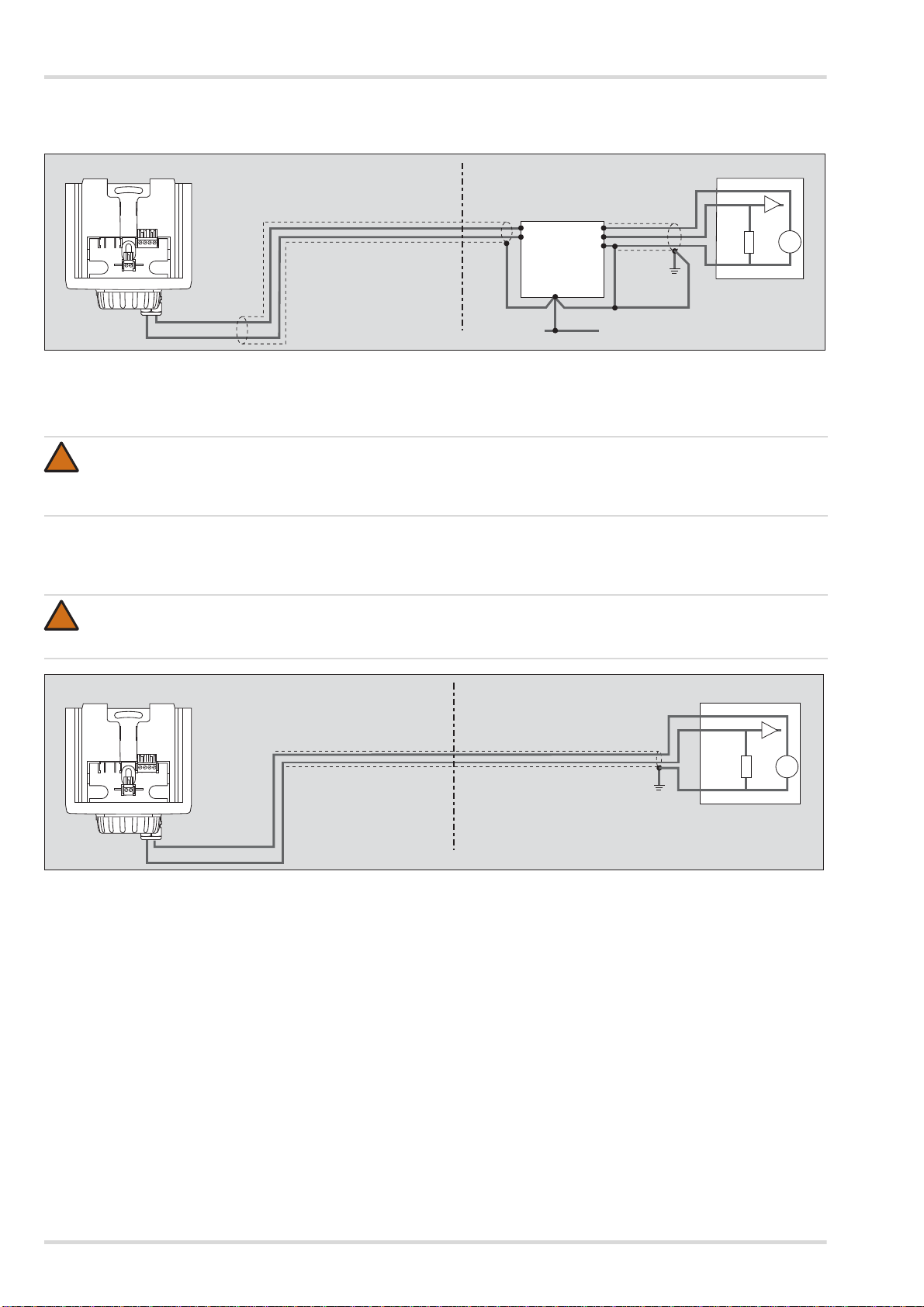

Safe connection to electrical devices

Electrical connections to devices which are not listed in

these Instructions for Use should only be made following

consultation with the respective manufacturers or an expert.

Use in potentially explosive atmospheres

Devices or components for use in potentially explosive

atmospheres, which have been tested and approved

according to national, European or international Explosion

Protection Regulations, may only be used under the

conditions specified in the approval and with consideration

of the relevant legal regulations. The devices or

components may not be modified in any manner. The use

of faulty or incomplete parts is forbidden. The appropriate

regulations must be observed at all times when carrying

out repairs on these devices or components.

1.2 Definitions of alert icons

The following alert icons are used in this document to identify

and highlight areas of the associated text that require a greater

awareness by the user. A definition of the meaning of each

icon is as follows:

2 Intended use

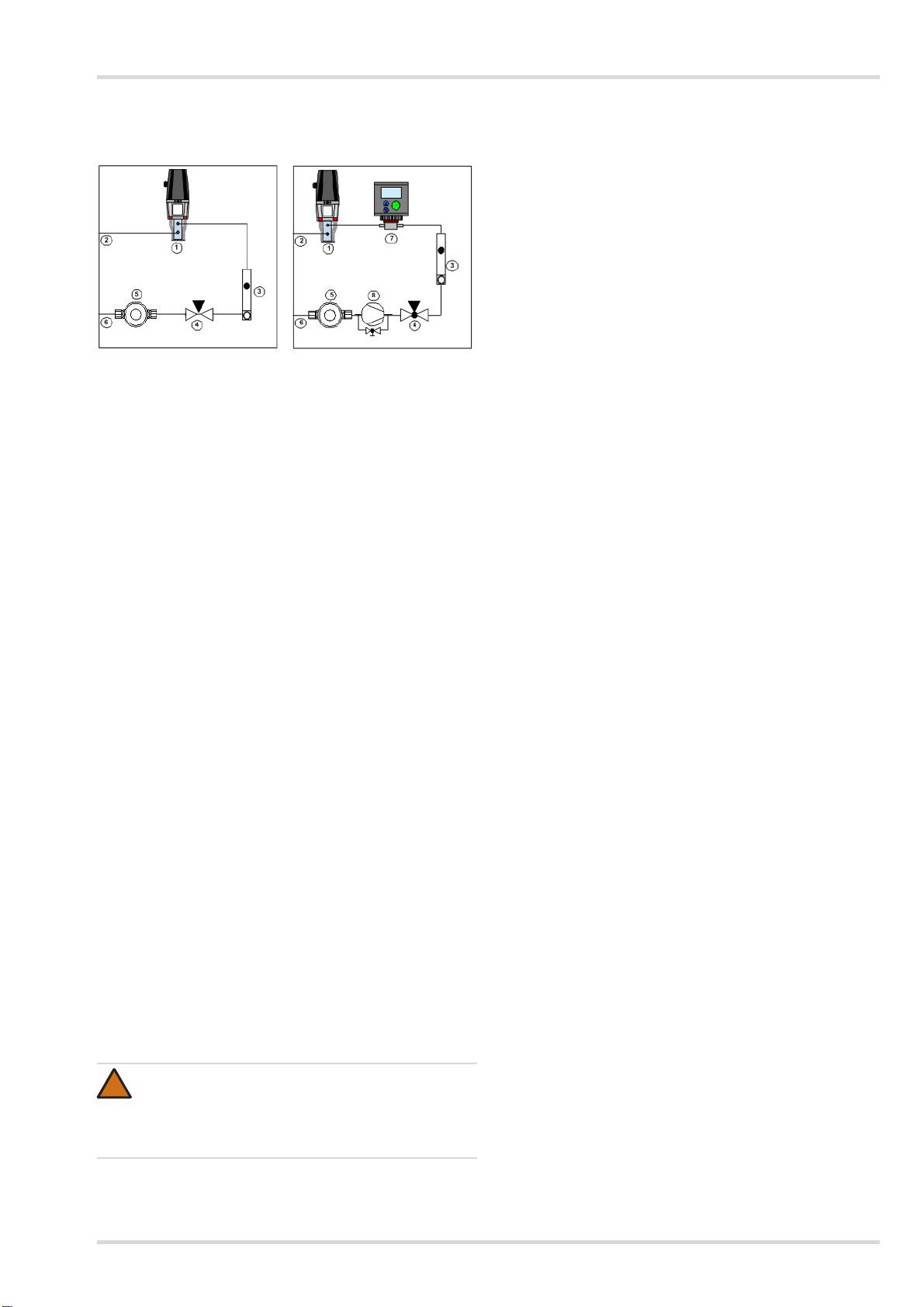

The Dräger SAM 3100/SAM 3200 is an aspirator system for

continual intake of gas/air mixtures for a gas transmitter

(SAM 3100) or for two gas transmitters (SAM 3200), in order

to carry out measurements of toxic and/or explosive

substances in hard-to-access places.

In the event of insufficient process overpressure, a partial flow

of the process gas is siphoned off from the process using

a gas sampling pump with electric drive, or alternatively using

an ejector.

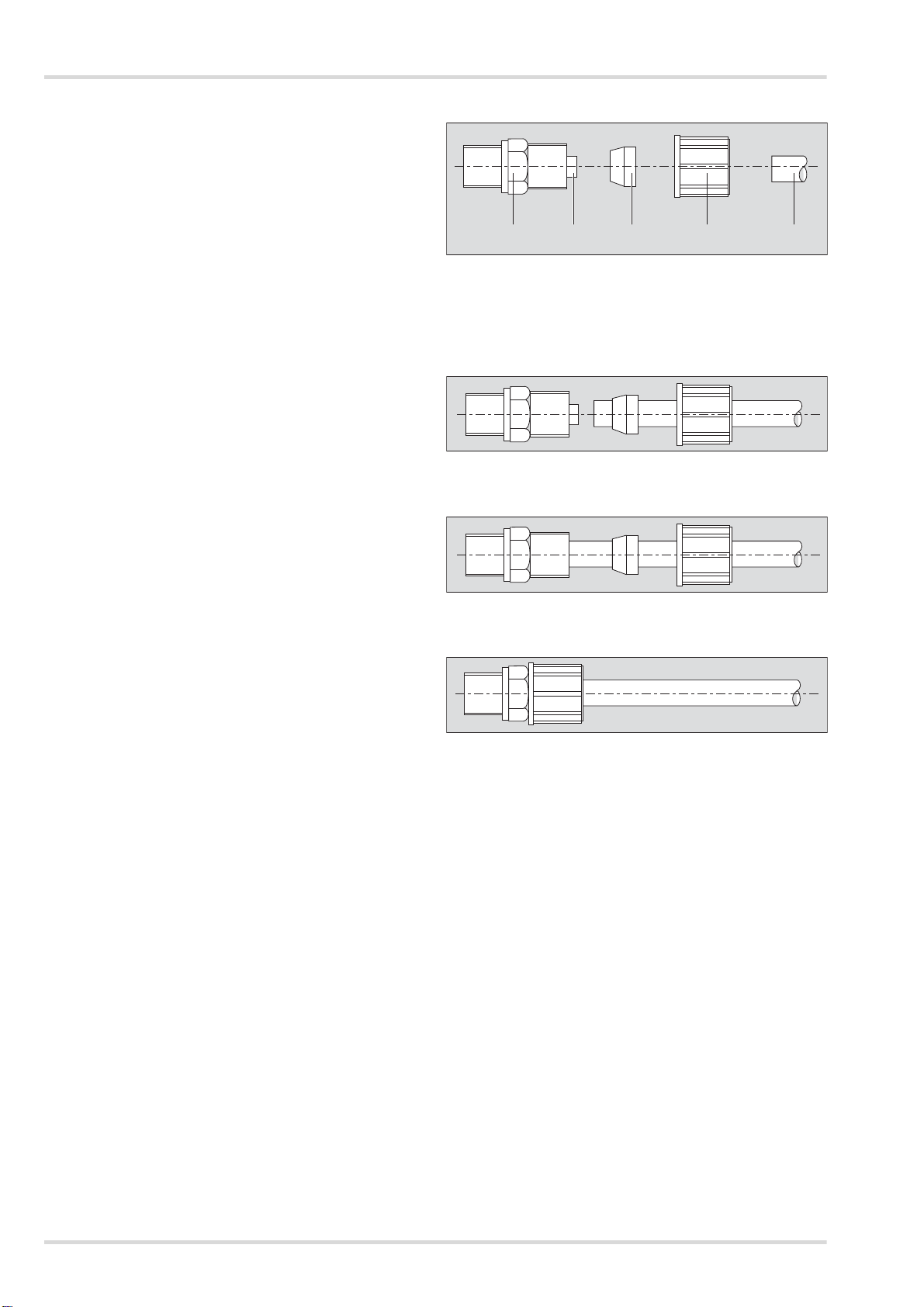

In order to separate solid particles from the gas flow,

the gas is passed across a filter.

The sample gas is passed to the flow meter with ring

initiator (for flow monitoring) via a 3/2-way spherical valve

(option for simplified feeding of test gas) and then flows into

the sample chamber of the sensor or sensors.

The air is either discharged to atmosphere or fed back

to the intake point by means of the air outlet on

the transmitter.

WARNING

The equipment is only approved for use in potentially

explosive atmospheres when using components

suitable for such areas, complete with test certificate.

Risk of explosion!

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, could result in physical injury, or damage to

the product or environment. It may also be used to

alert against unsafe practices.

NOTICE

Indicates additional information on how to use

the product.

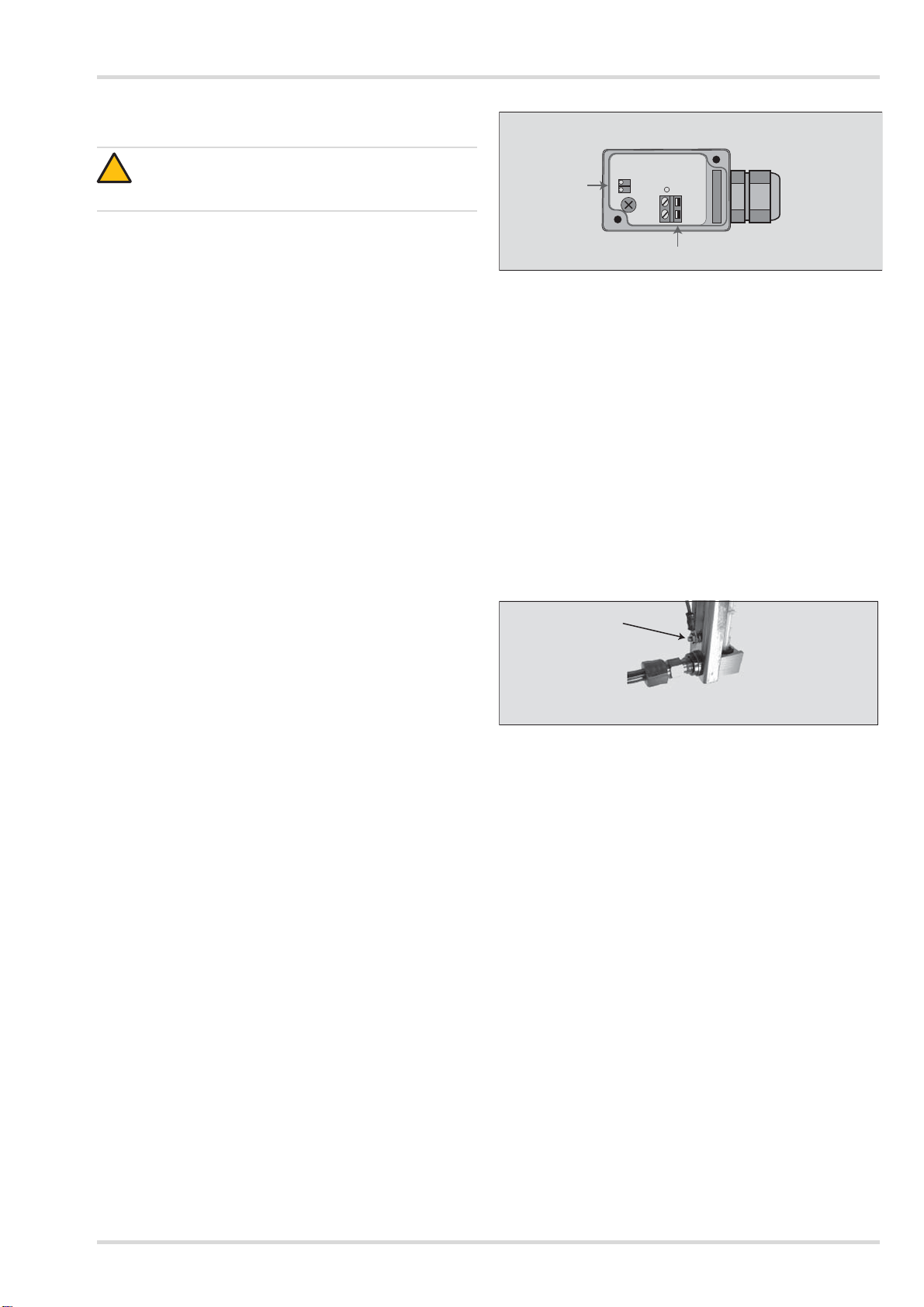

WARNING

During installation without return feed for the sample

gas back to the intake point, the sample gas should be

guided to a vent or outside. Risk of poisoning or

explosion! The return feed must not be pressurised.

!

i

i