Manual

V1.1 Mk1 Page 2of 23

Table of Contents

Introduction ............................................................................................................................................4

Important Health and Safety Information ............................................................................................4

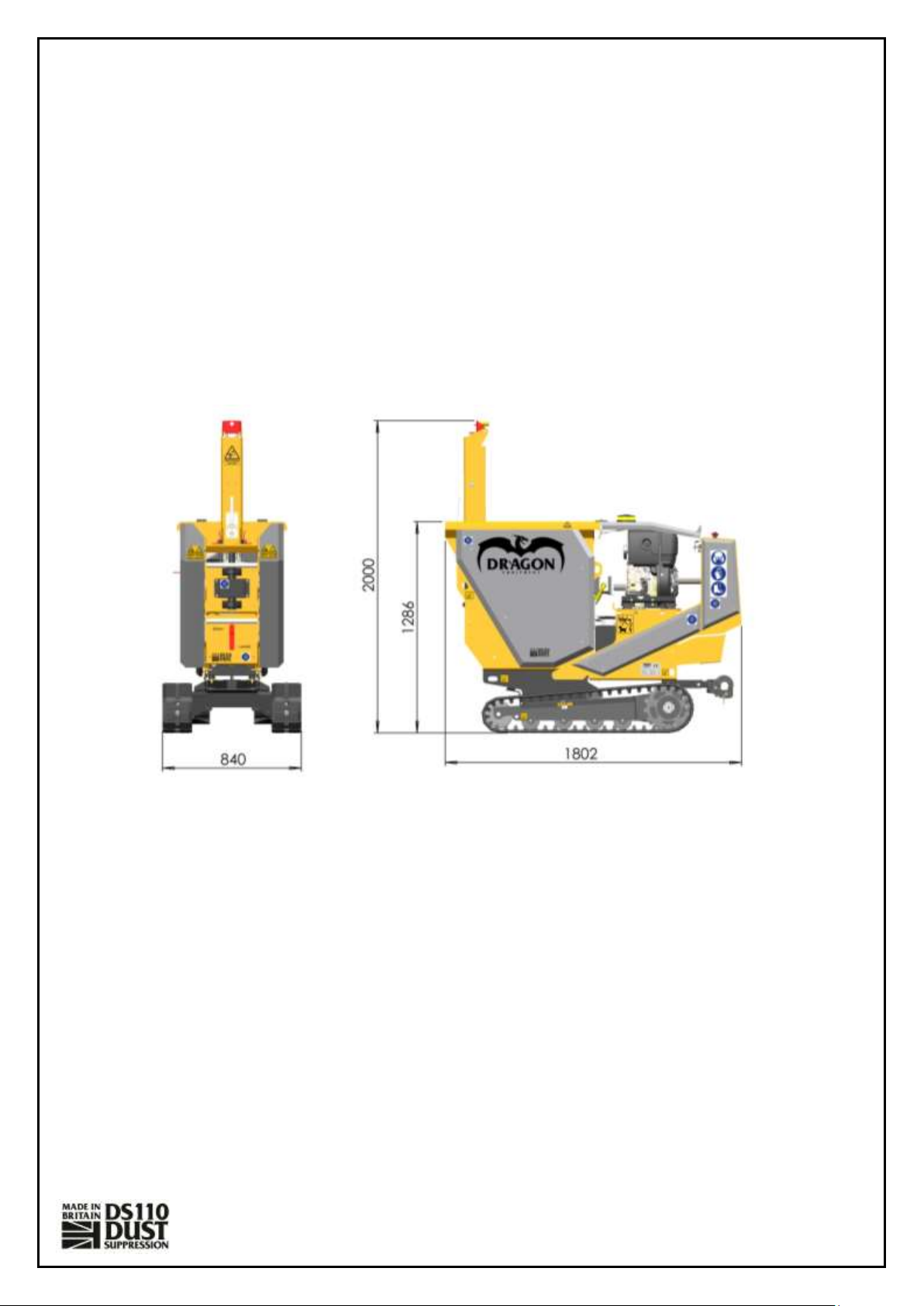

Specifications ..........................................................................................................................................5

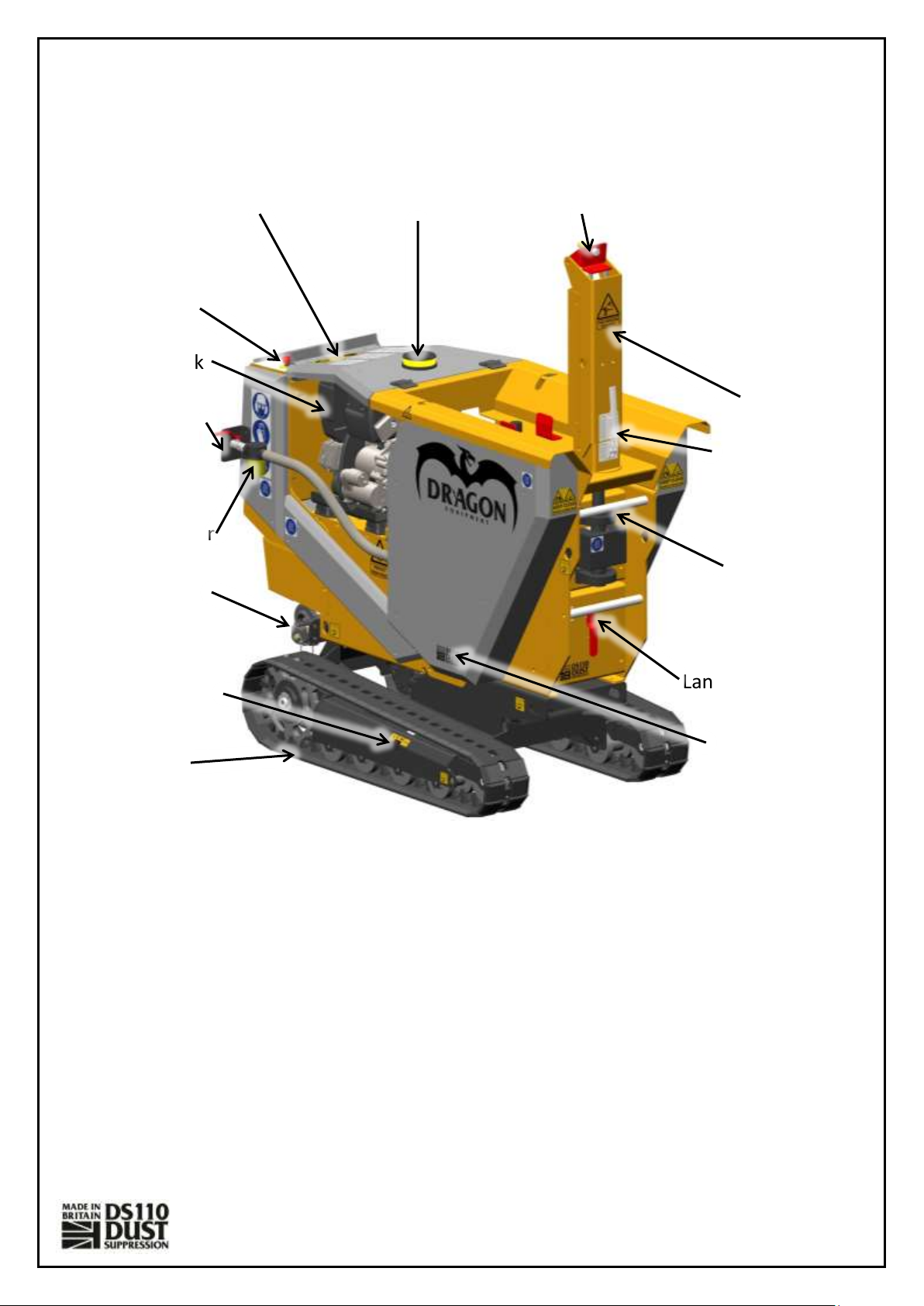

Parts Locator........................................................................................................................................6

Safe Working...........................................................................................................................................7

Operator’s Personal Protective Equipment (PPE).................................................................................7

Basic Operation Safety.........................................................................................................................7

General Safety Matters........................................................................................................................7

Engine Noise........................................................................................................................................8

Refuelling.............................................................................................................................................8

Operating Instructions............................................................................................................................9

Storage and Parking...........................................................................................................................10

Starting the Machine .........................................................................................................................10

Checks Before Starting..................................................................................................................10

Starting Procedure........................................................................................................................10

......................................................................................................................................................11

Stopping the Engine...........................................................................................................................11

Emergency Stopping ..........................................................................................................................11

Operating the Machine......................................................................................................................12

Checks Before Tracking.................................................................................................................12

Tracking the Machine....................................................................................................................12

Spraying Water ..................................................................................................................................12

Checks Before Spraying Water......................................................................................................12

Manual Water Mode.....................................................................................................................12

Using the Teach/Auto Function ....................................................................................................12

Using the High-Pressure Lance .....................................................................................................13

Lowering the Mast ........................................................................................................................13

Service Instructions...............................................................................................................................14

Service Schedule................................................................................................................................15

Engine Servicing ............................................................................................................................15

Hydraulic Hose Check....................................................................................................................15

Changing Hydraulic Oil Filter.........................................................................................................16

Changing Hydraulic Oil and Filter..................................................................................................16

Grease Moving Parts.....................................................................................................................17

Grease Bearings ............................................................................................................................17