CONTENTS

I. Main performance and characteristics of the product................................................ 3

II. Precautions....................................................................................................................... 3

III. Range of application.......................................................................................................5

IV. Preparation for use.........................................................................................................5

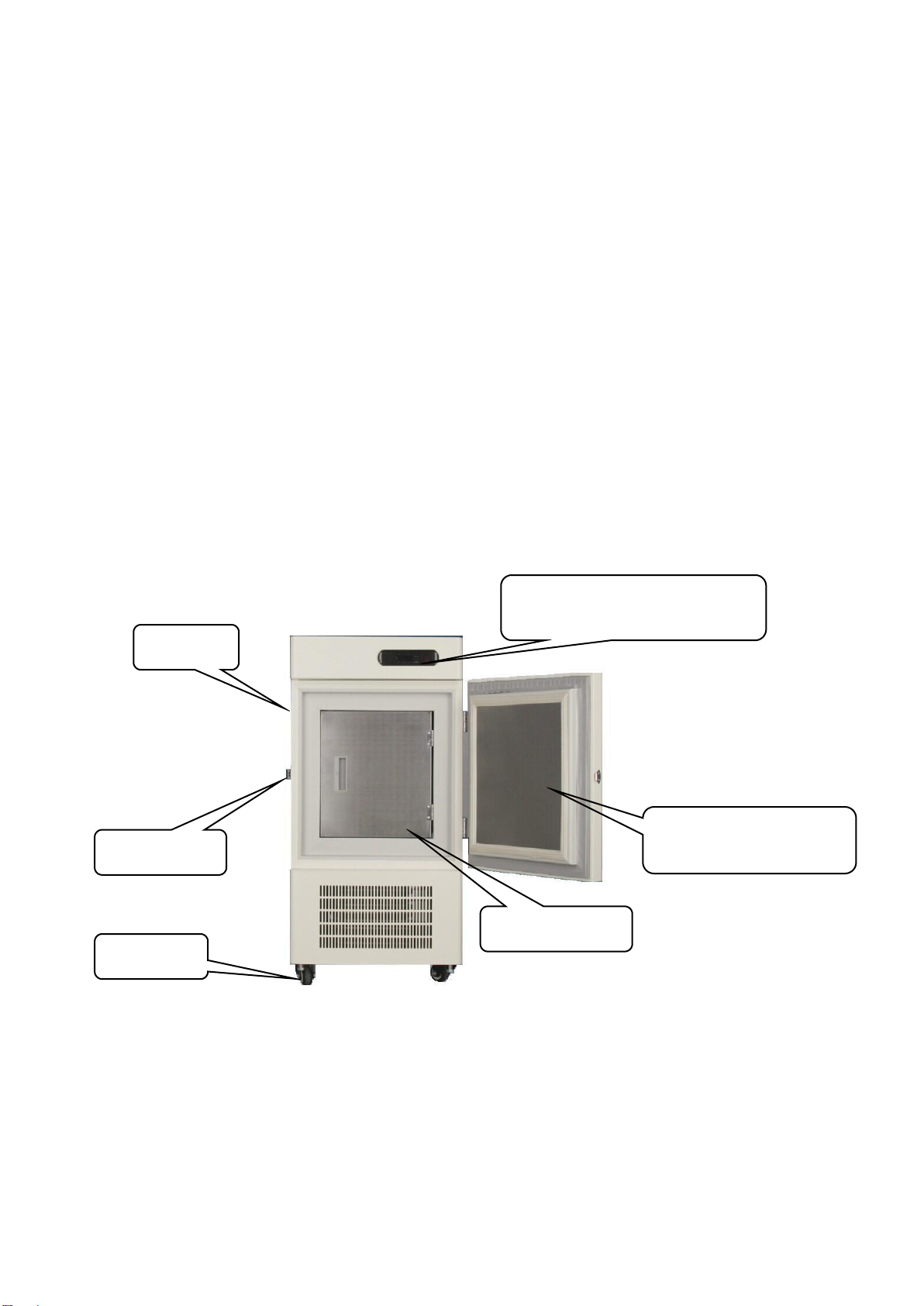

V. Structure diagram............................................................................................................5

VI. Start and test machine.................................................................................................. 6

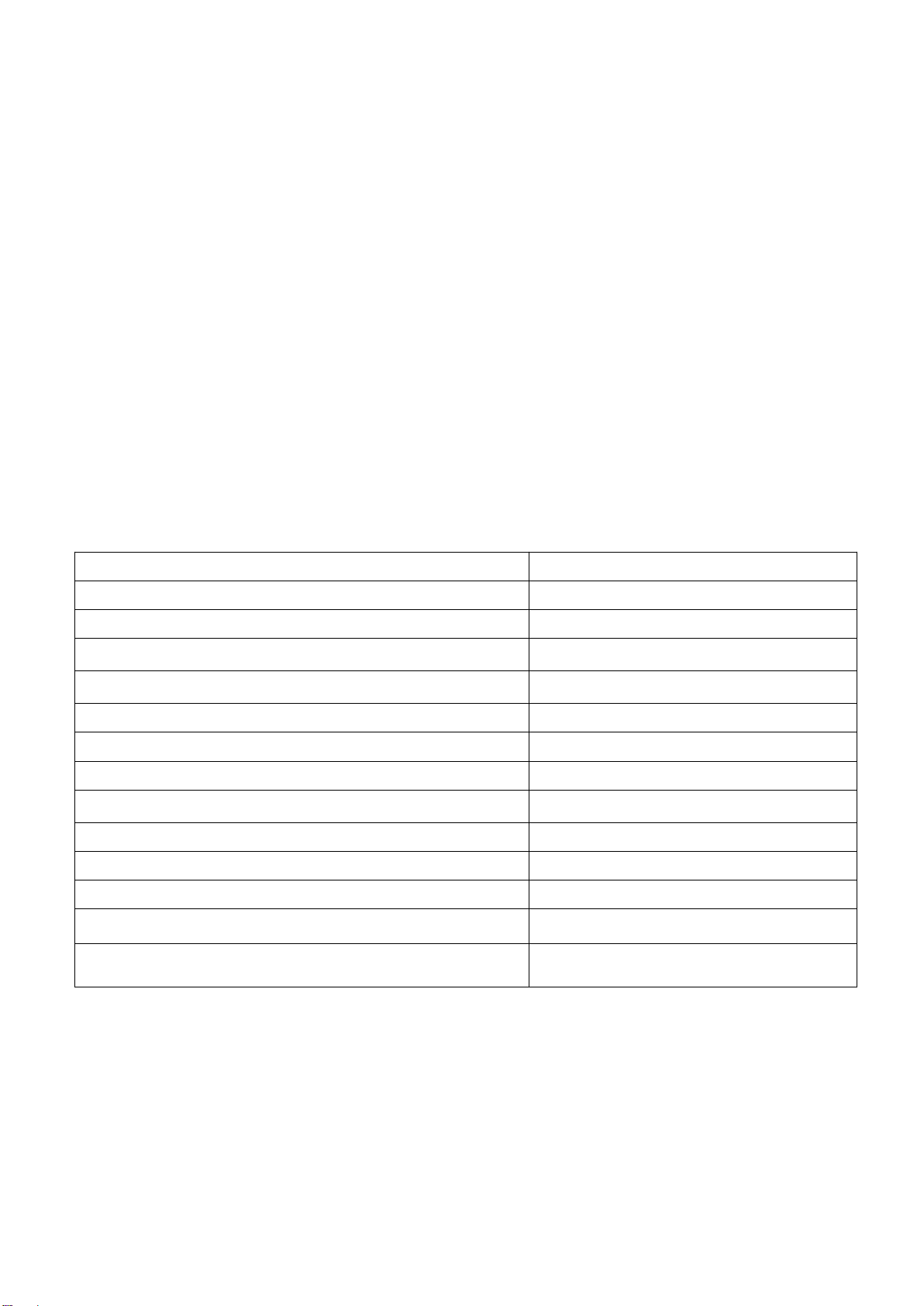

VII. Model and main technical parameters...................................................................... 6

VIII. Functions and basic operation of controller............................................................ 7

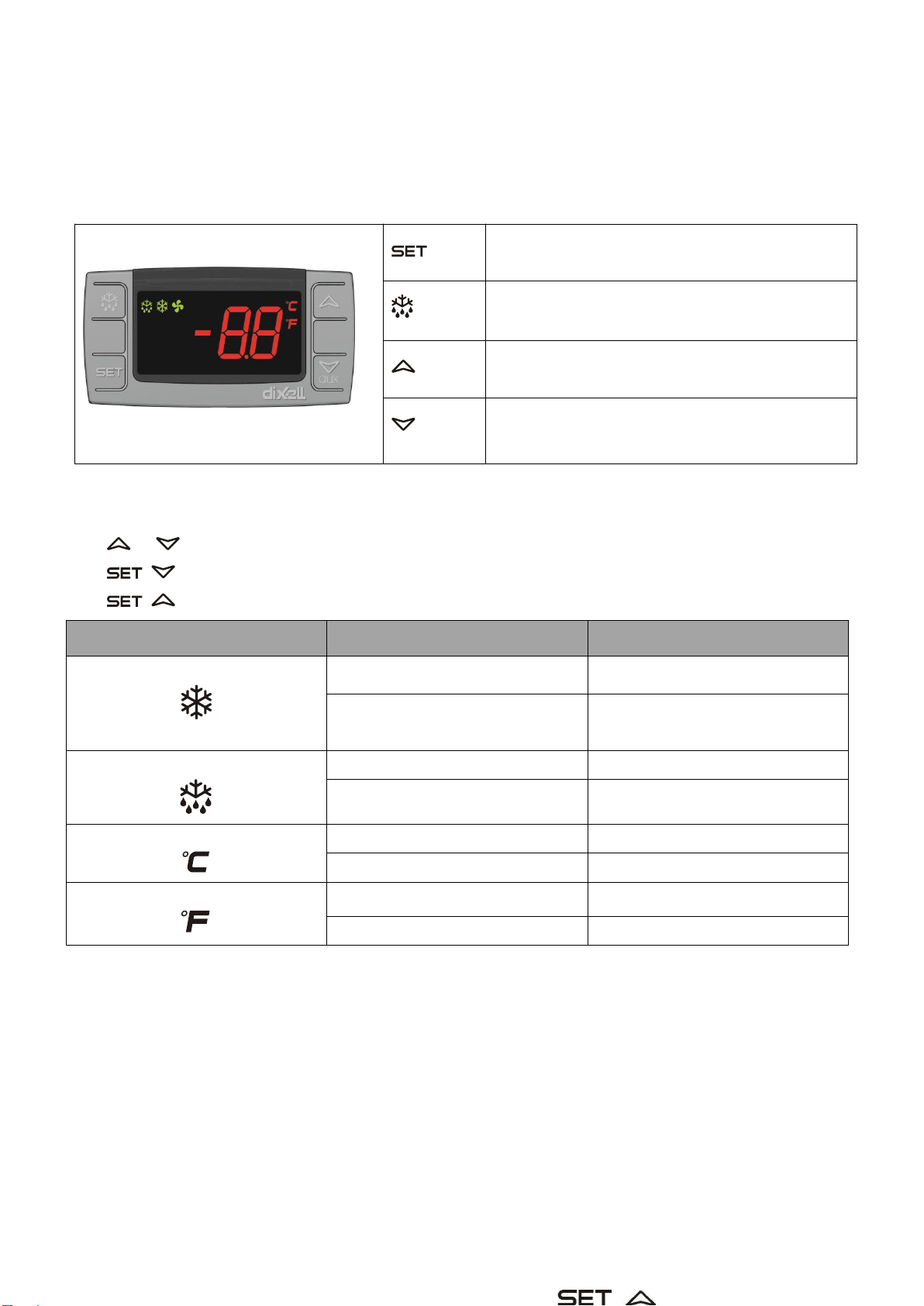

8.1 Control panel structure........................................................................................... 7

8.1.1 Keys Combination..........................................................................................7

8.1.2 How to see the set point............................................................................... 7

8.1.3 How to change the set point.........................................................................7

8.1.4 How to start a manual defrost (only xr02cx)............................................. 8

8.1.5 How to change parameter value................................................................. 8

8.2 parameters................................................................................................................8

8.3 Digital inputs...........................................................................................................10

8.4 Alarm signaling...................................................................................................... 10

8.4.1 alarm recovery..............................................................................................11

8.5 connection diagram...............................................................................................11

8.5.1XR01-02CX –1 X 8A –12VAC/DC....................................................11

8.5.2 XR01-02CX –20A OR 8A -- 110VAC OR 230VAC...........................11

IX. Schematic circuit diagram.......................................................................................... 12

X. Storage essentials.........................................................................................................12

XI. Maintenance..................................................................................................................13

XII. Non-fault phenomenon.............................................................................................. 13

XIII. General fault analysis and removal........................................................................ 14

XIV. Packing List................................................................................................................ 14