CON-2

Page 1

Contents

Section Subject Page

Product Safety Sign and Label System..................................................................... Inside Front Cover

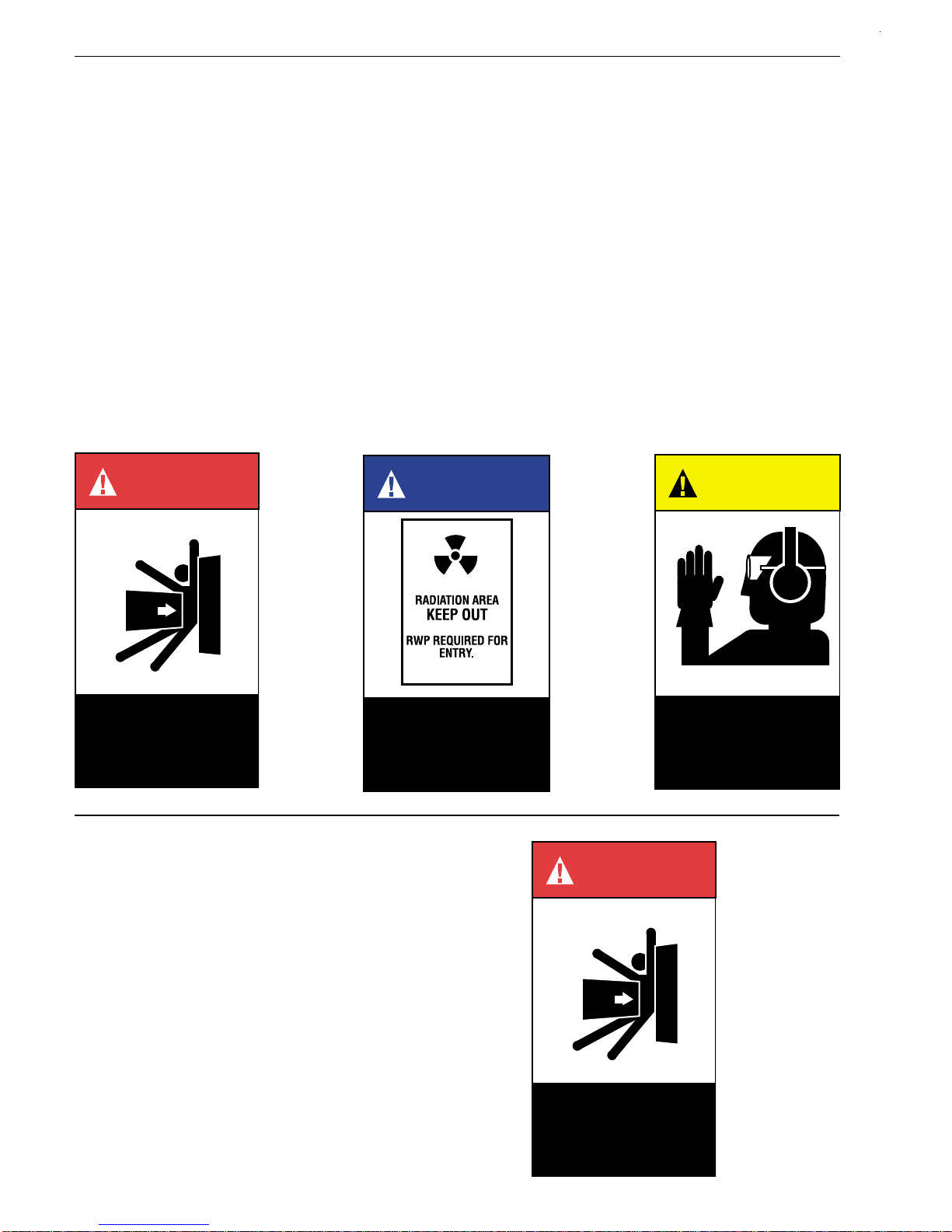

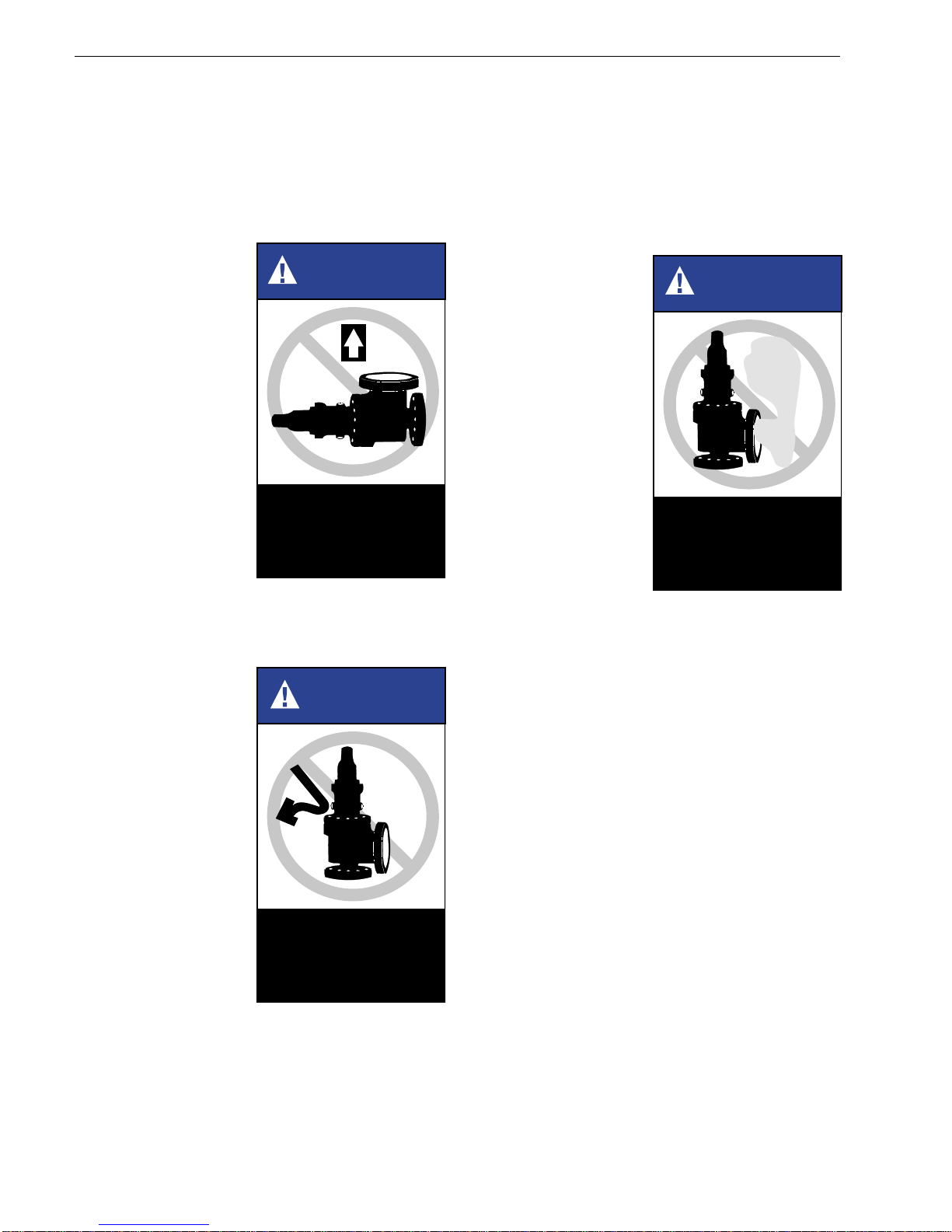

I. Safety Alerts .................................................................................................................................. 2

II. Terminology for Safety Relief Valves ............................................................................................ 4

III. Introduction ................................................................................................................................... 5

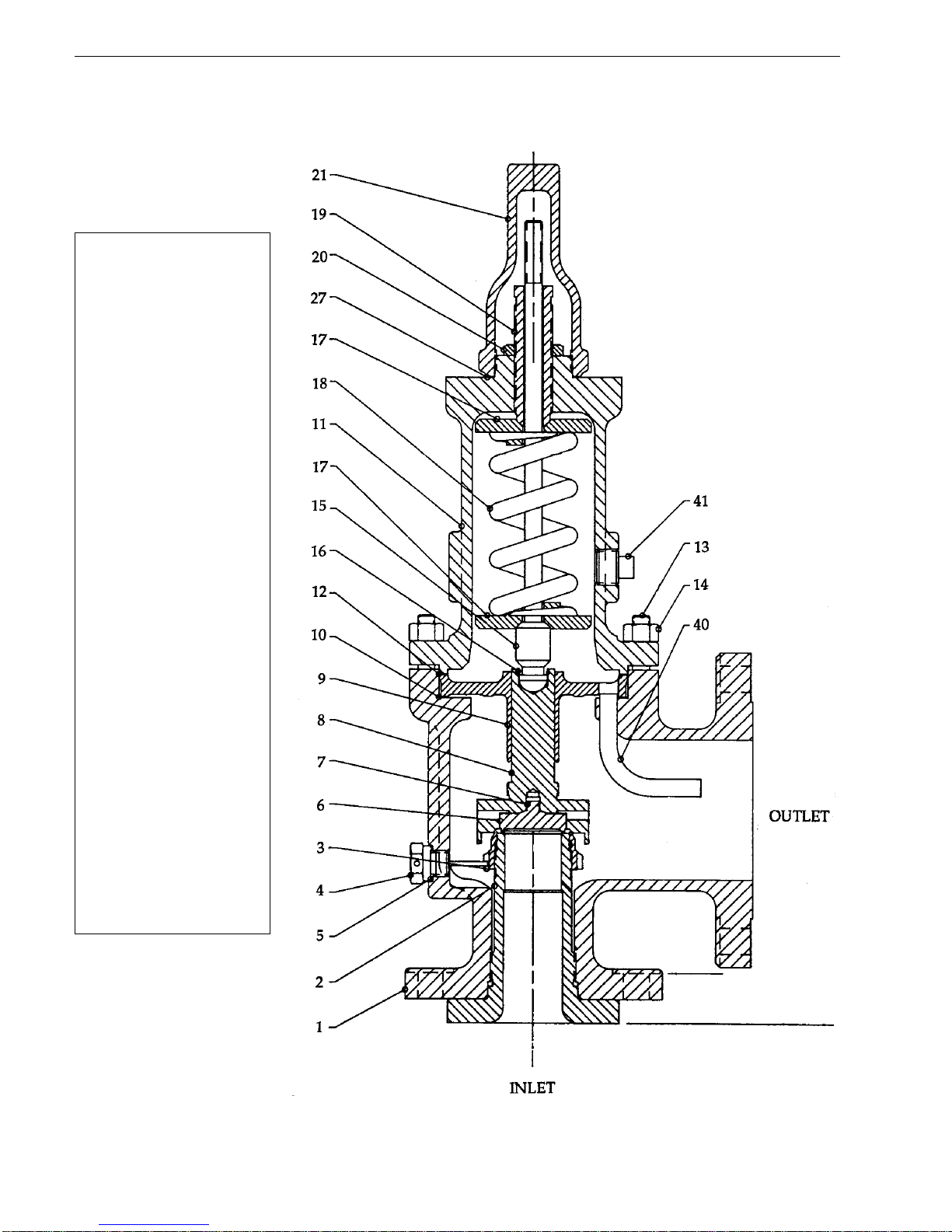

IV. Design Features and Nomenclature .............................................................................................5

V. Handling, Storage and Pre-Installation ......................................................................................... 8

VI. Recommended Installation Practices ............................................................................................ 9

A. Mounting Position ................................................................................................................ 9

B. Inlet Piping ........................................................................................................................... 9

C. Outlet Piping ........................................................................................................................ 11

VII. Disassembly Instructions .............................................................................................................. 12

A. General Information ............................................................................................................. 12

B. Specific Steps ...................................................................................................................... 12

VIII. Cleaning ........................................................................................................................................ 14

IX. Parts Inspection ............................................................................................................................ 14

A. Nozzle.................................................................................................................................. 14

B. Nozzle Seat Width ............................................................................................................... 16

C. Nozzle Bore ......................................................................................................................... 16

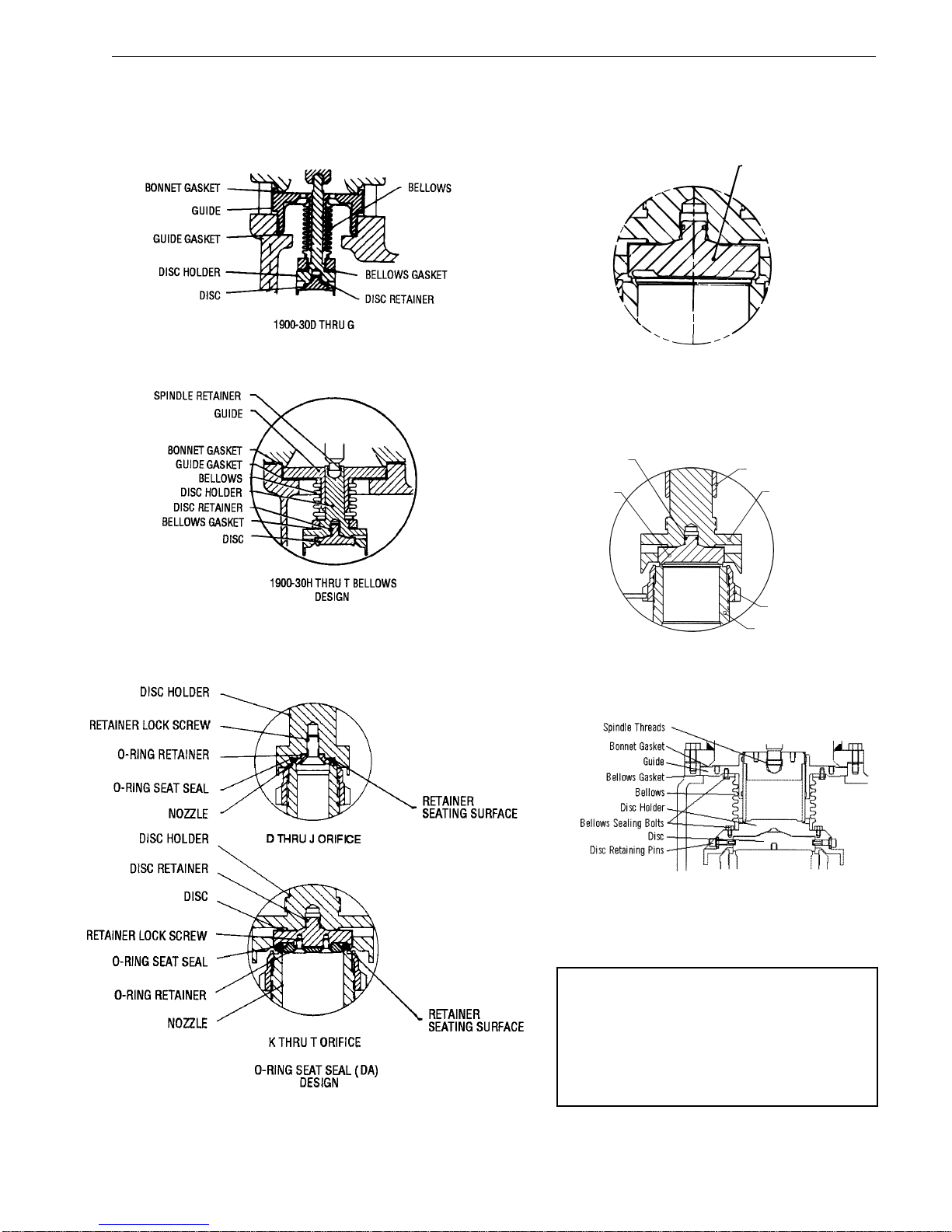

D. 1900, 1900-30 Standard Disc .............................................................................................. 16

E. 1900 Series Thermodisc...................................................................................................... 17

F. Disc Holder .......................................................................................................................... 18

G. Guide ................................................................................................................................... 21

H. Spindle................................................................................................................................. 21

I. Spring .................................................................................................................................. 21

X. Maintenance Instructions .............................................................................................................. 22

A. General Information ............................................................................................................. 22

B. Lapping Nozzle Seats (Non O-Ring Styles) ........................................................................ 22

C. Nozzle Seat Widths-Lapped ................................................................................................ 22

D. Lapping Disc Seats.............................................................................................................. 24

E. Precautions and Hints for Lapping Seats ............................................................................ 24

F. Lapping O-Ring Seating Surfaces ....................................................................................... 24

G. Reconditioning of Laps ........................................................................................................25

H. Remachining Nozzle Seats and Bores ................................................................................ 25

I. Remachining the Disc Seat ................................................................................................. 26

J. Checking Spindle Concentricity ........................................................................................... 27

K. Set Pressure Change-Disc Holder ...................................................................................... 28

L. Checking Lift on Restricted Lift Valves ................................................................................ 28

XI. Reassembly................................................................................................................................... 29

A. General Information ............................................................................................................. 29

B. Lubrication ........................................................................................................................... 30

C. Specific Steps ...................................................................................................................... 30

XII. Setting and Testing ....................................................................................................................... 35

A. General Information ............................................................................................................. 35

B. Test Equipment ................................................................................................................... 35

C. Test Media ........................................................................................................................... 35

D. Setting the Valve ................................................................................................................. 35

E. Set Pressure Compensation................................................................................................ 35

F. Seat Tightness Testing ........................................................................................................37

XIII. Hydrostatic Testing and Gagging .................................................................................................. 38

XIV. Manual Popping of the Valve ........................................................................................................ 39

XV. Conversion of Type 1900 Flanged Safety Relief Valves

From Conventional to Bellows Type, and Vice Versa ................................................................... 40

A. General Information ............................................................................................................. 40

B. Conversion From Conventional to Bellows Type................................................................. 41

C. Conversion From Bellows to Conventional Type................................................................. 41

XVI. Trouble Shooting Type 1900 Valves ............................................................................................. 42

XVII. Maintenance Tools and Supplies .................................................................................................. 42

XVIII. Replacement Parts Planning......................................................................................................... 44

A. Basic Guidelines .................................................................................................................. 44

B. Replacement Parts List ....................................................................................................... 44

C. Identification and Ordering Essentials ................................................................................. 44

XIX. Genuine Dresser Parts.................................................................................................................. 45

XX. Recommended Spare Parts for the 1900 Safety Relief Valves .................................................... 46

XXI. Manufacturer's Warranty, Field Service & Repair Program .......................................................... 48

A. Warranty Information ........................................................................................................... 48

B. Field Service ........................................................................................................................ 48

C. Factory Repair Facilities ...................................................................................................... 48

D. Safety Relief Valve Maintenance Training........................................................................... 48

Appendix RE: Optional Glide-Alloy® Parts ................................................................................... A.1

Service Engineers and Sales Office Locations ......................................................... Back Cover