6

Instructions EM36005 – 07/10

36005 Series V-Max® Control Ball Valve

Ensure rotation of AC actuator does not exceed

90deg. Damage to actuator rod may result.

K. If actuator action is air to open, rotate ball plug (2) to

open position. Pneumatically stroke actuator to open

position. Loosen rod end bearing locknut (93) and

adjust position of rod end bearing (94) so that holes

in lever (32) and rod end bearing (94) line up. Insert

pivot pin (39) and retaining rings (40).

When stroking valve keep hands and equipment

clear of ball plug and seal ring to avoid injury or

damage to personnel and equipment.

L. If action is air to close place ball plug (2) in closed

position. The pad on lever should contact the closed

position travel stop (102). If it does not, repeat

adjustment as noted in step I above. Return ball plug

(2) to open position. Pneumatically stroke actuator to

open position.

Do not exceed maximum air supply pressure. Keep

hands clear of actuator stem and linkage.

Loosen rod end bearing locknut (93) and adjust rod

end bearing (94) so that holes in lever (32) and rod

end bearing (94) line up. Insert pivot pin (39) and

replace retaining rings (40).

M. For both air to open and air to close action, stroke valve

fully to ensure proper closure of ball plug and operation

of valve. It may be necessary to readjust rod end

bearing slightly by loosening locknut and rotating stem.

N. Replace handwheel assembly in housing (31),

washer (54-7) and retaining clip (54-4).

O. Replace shaft cover (42) and screw (43).

P. Set and lock indicator arm (35) to indicate plug position.

2.5 Changing Valve Action

Note: If the valve action is to be changed it should be done

before the valve is installed in the line. This allows a positive

visual check to ensure that the ball plug is fully closed when

the actuator is in the proper position.

2.5.1 Model 33, sizes B & C only. For size AC refer

to section 2.5.2

A. If the valve is equipped with a handwheel disengage

the handwheel and remove retaining clips (63), clevis

pin (66), and pivot pins (39). Remove cap screws

(70), washers (71) and handwheel bracket (62).

B. If necessary, scribe a witness mark on the lever (32)

in relation to the slot on the end of the shaft (5).

Note: Standard lever has arrows stamped into it for

alignment. For handwheel lever use slot for alignment.

C. Remove pivot pin retaining clips (40), pivot pin (39)

and spacer rings (69). Remove shaft cover (42)

and screw (43). Remove actuator hex nuts (75) and

washers (76). Remove actuator.

Note: Spacer rings apply only on handwheel option.

D. Loosen lever cap screw (33). Remove packing flange

stud nuts (24), bracket mounting stud nuts (24) and

washers (18). Loosen ball plug indicator arm (35).

E. Slide bracket (31) away from body until it clears bracket

and packing flange mounting studs. Remove lever

(32), lever arm (64) and indicator arm (35) from shaft.

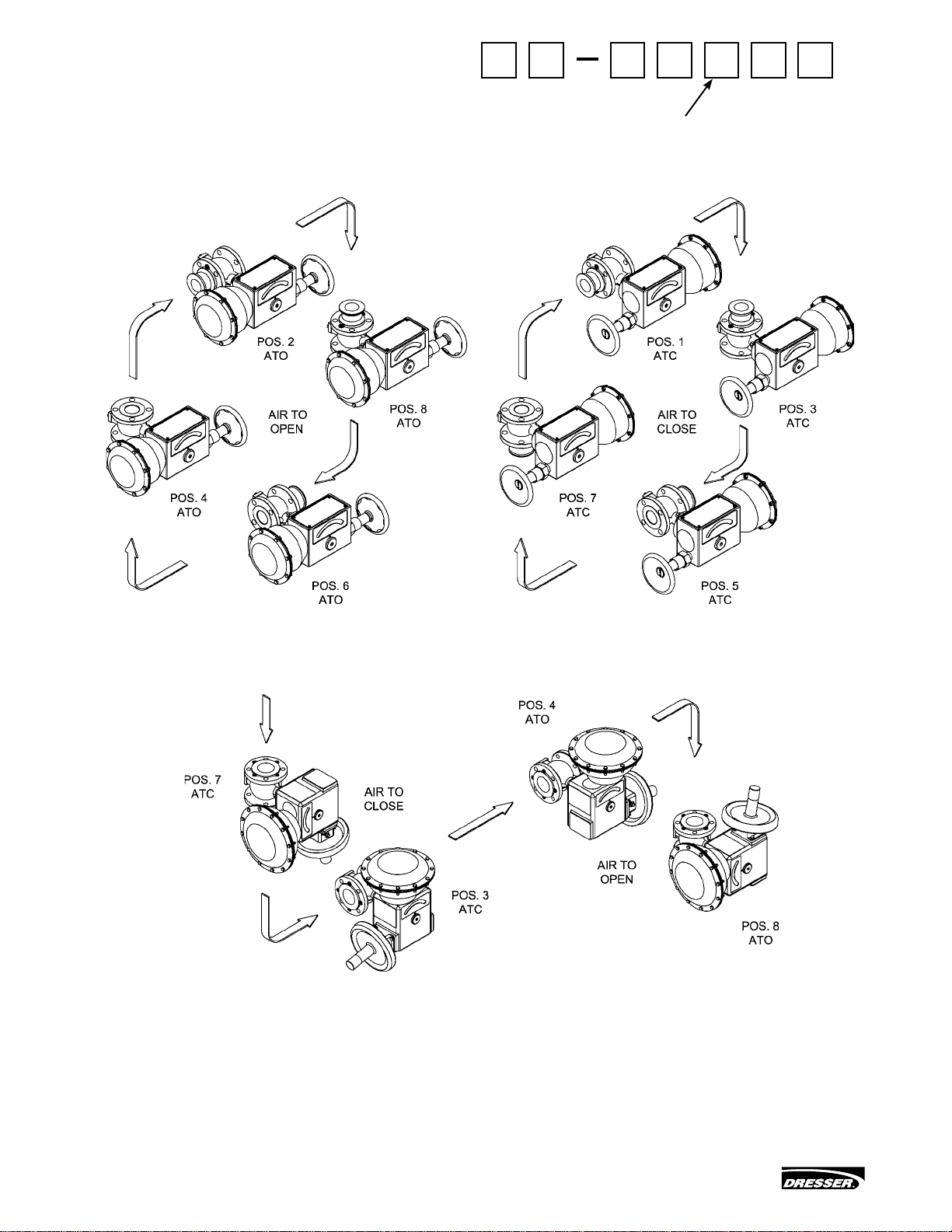

Before proceeding determine valve action (air to open/

air to close), refer to the appropriate figure (Figure 10 to

open, Figure 11 to close). To obtain proper alignment,

the lever must be oriented on the shaft so that the slot

in the end of the shaft and arrows or indicator lines are

aligned as shown; with the ball in the closed position,

the distance between the top of the bracket and the

top of the pivot pin must be as shown.

F. Flip lever (32) and lever arm (64) and replace on

shaft 90 away from original position. Replace

indicator arm (35). Slide bracket back onto bracket

mounting studs (26), replace washers (18) and nuts

(24) and tighten. Slide packing flange (23) back

over packing flange studs (25) and replace packing

flange stud nuts (24) and tighten.

G. Replace actuator on bracket in correct mounting

position for air action. Replace actuator stud nuts

(75) and washers (76). Position lever (32) and lever

arm (64) so that rod end bearing (94) lines up in lever

(32). Tighten lever cap screw (33).

H. Place ball plug (2) in closed position. If actuator

action is air to open, loosen rod end bearing nut (93)

and adjust position of rod end bearing (94) so that

holes in lever (32) and rod end bearing (94) line up.

Insert pivot pin (39) and replace retaining rings (40).

I. If action is air to close, place ball plug (2) in closed

position and pneumatically stroke actuator fully.

Do not exceed maximum air supply pressure.

J. For both air to open and air to close action, stroke valve

fully to ensure proper closure of ball plug and operation

of valve. Tighten rod end bearing locknut (93).

When stroking valve keep hands and equipment

clear of ball plug and seal ring to avoid injury or

damage to personnel or equipment.

K. Replace handwheel bracket (62), cap screws (70)

and lockwashers (71) on opposite side of actuator

bracket from where originally found. Insert handwheel

assembly in bracket and replace clevis pin (66),

retaining rings (63), lever arm bearing (65) and pivot

pins (72). Replace shaft cover (42) and screw (43).