Instruction No EF 5000 E

01/2004

5

Care must be exercised when unpacking the valve to

prevent damage to the accessories and component

parts. Should any problems arise, contact the

Masoneilan Representative or District Office.

Note: For ease of shipment and to prevent damage,

valves equipped with the spring diaphragm actuator

are shipped with the handwheel unassembled. Refer

to section 10.3 for handwheel assembly procedures.

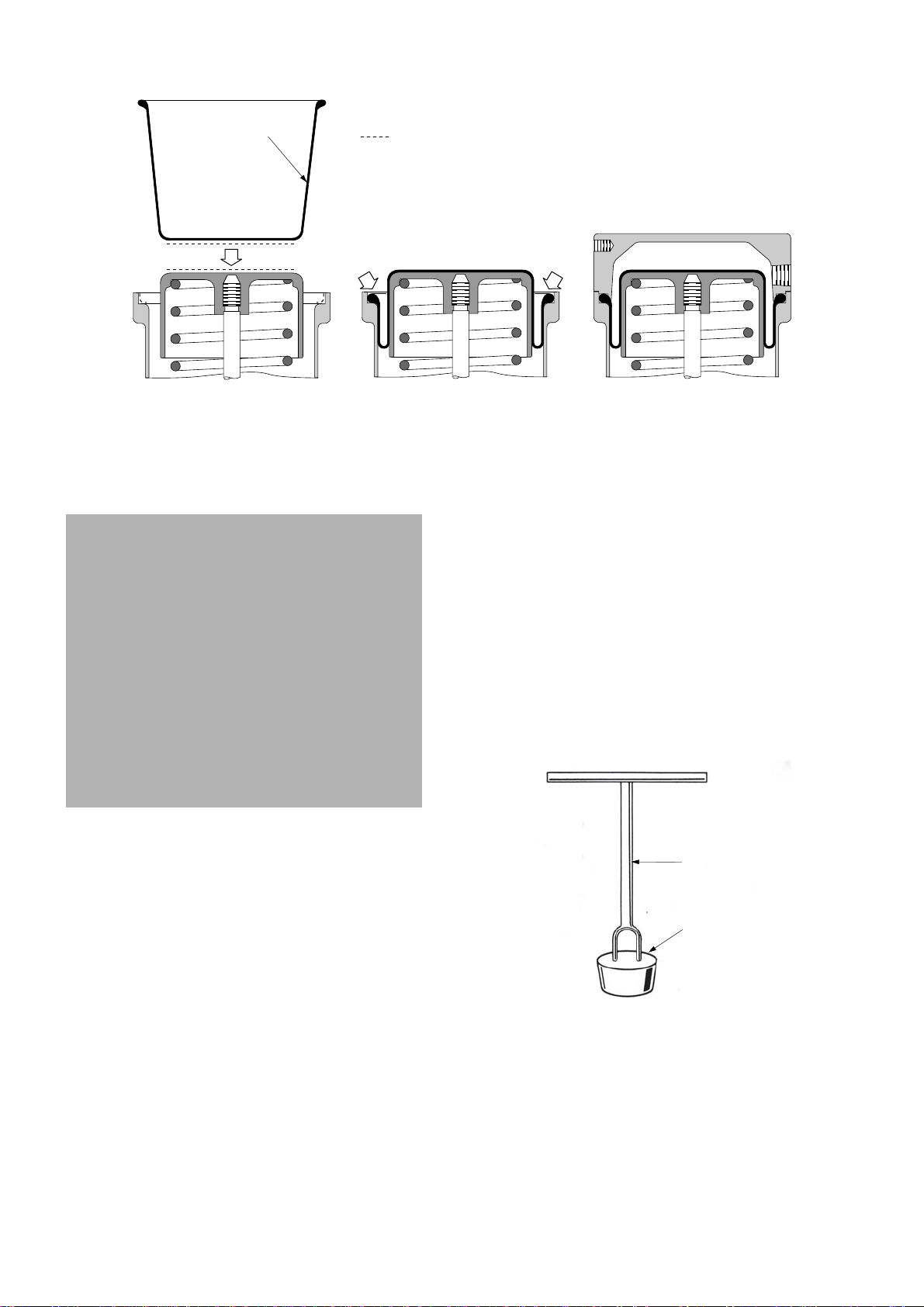

The Camflex® II valve has been assembled at the

factory in accordance with specify instructions

concerning flow direction and actuator mode. The

valve must be installed so that the controlled

substance will flow through the valve in the direction

indicated by the flow arrow (25), which is located on

the upper part of the valve body neck. The valve

actuator should be installed so the actuator is above

the centerline of the shaft. To install the valve in the

line, proceed as follows:

A. Check the model number on the serial plate (56)

against the numbering System described in

figure 1 to determine the valve mode.

B. Clean piping and valve of ail foreign material

such as welding chips, scale, oil, grease or dirt.

Gasket surfaces should be thoroughly cleaned to

insure leak proof connections.

C. To allow for in-line inspection, maintenance or

removal of the valve without service interruption,

provide a manually operated stop valve on each

side of the Camflex® II valve with a manually

operated throttling valve mounted in the by-pass

line.

Note: If a flanged Camflex® II is being installed

and the distance between flanges is established

by ANSI or DIN, spool pieces (spacers) are

inserted between the line flange and the valve

body flange. Gaskets and valve bolting are then

installed and torqued using standard flange and

line bolting criteria.

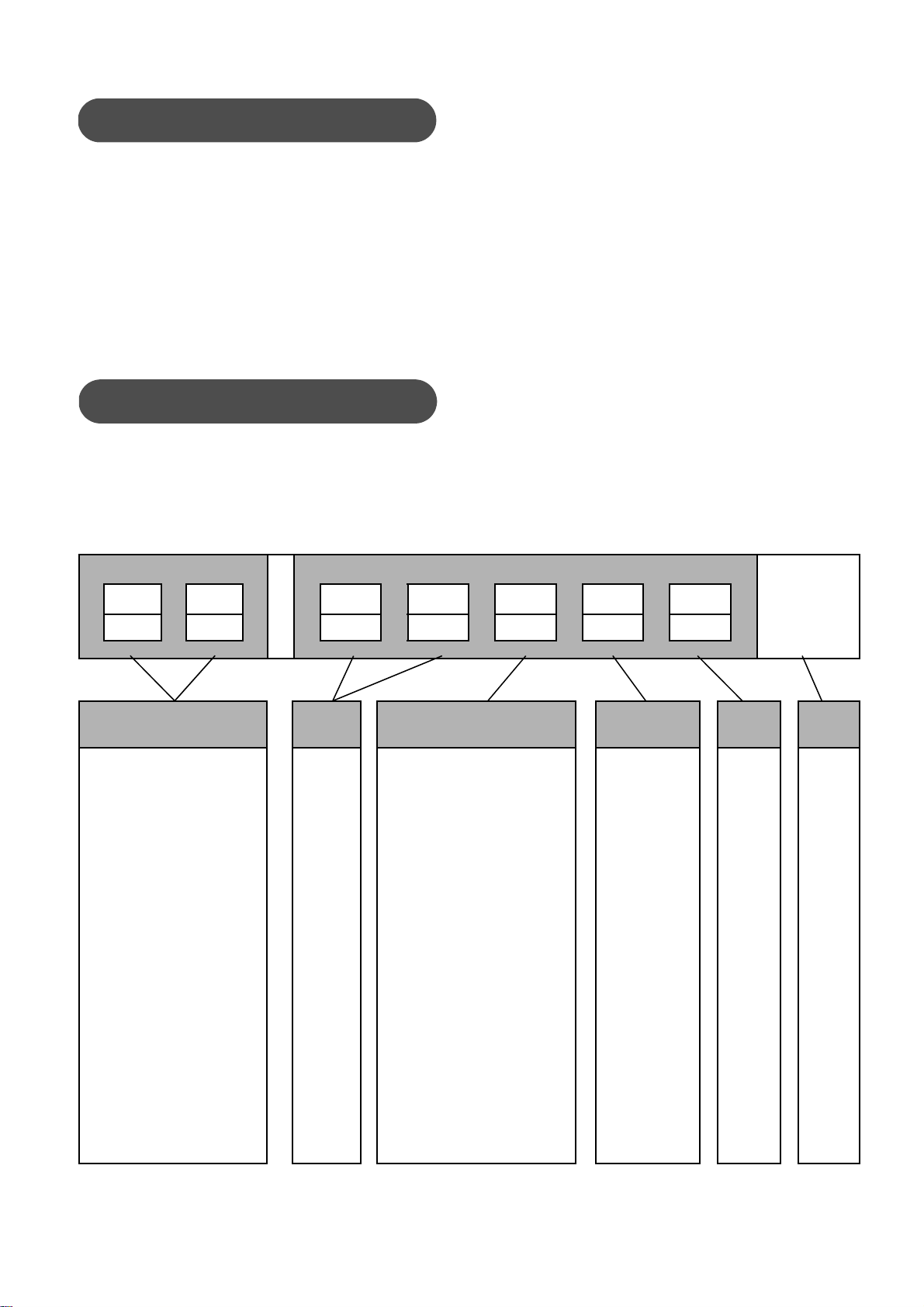

D. For flangeless valves, refer to figure 23 and

determine the correct size and quantity of bolts

to be used for the valve and flange rating.

E. If the valve is to be installed in a horizontal

position, install the lower flange bolting to

provide a cradle, which will help support, the

valve while installing the remaining bolts.

F. Place the valve in the line.

G. Select and install correct gaskets.

Note: Spiral wound gaskets, suitable for service

conditions are recommended.

H. Insert remaining flange bolting insuring that the

bolts align with the special bosses on the body,

which assure the valveis centered in the line and

also prevent rotation.

Note: For certain flange standards, through

bolting is not possible because of the valve body

neck or bonnet. To accommodate flange bolting,

guide arms with threaded holes or slots are

provided on the valve body to receive flange

bolts (refer to figure 22).

I. Tighten flange bolts evenly and firmly.

Note: If the valve is equipped with manual

handwheel, it may now be placed in service.

Air is supplied to the actuator through the 1/4" NPT

tapped connection in the diaphragm case. Refer to

figure 14 to determine the correct supply pressure

and tubing size, then connect air supply piping.

Note: When the valve is equipped with regulators or

other accessories supplied by Masoneilan, only

connections to those accessories are required since

the piping to the actuator is connected at the factory.

Some valves equipped with electrical accessories

will require appropriate wiring. Refer to

manufacturer's instructions for correct wiring

information.

With the valve properly installed in the line and all air

or electrical service connected, it is recommended

Caution: Any change in flow direction or

actuator mode must be accomplished as

outlined. In this instruction otherwise

equipment malfunction could result.

4. Unpacking

5. Installation

Cantion: If the valve is to be insulated, do not

insulate the valve body neck.

Caution: Do not exceed maximum air

pressure indicated. Personal injury and

equipment malfunction could result.

6. Air Supply Piping

7. Placing in Service