07-02292A F571-115V 2 Dri-Eaz Products, Inc.

maintain a healthy level of humidity. Using the Cube may

also prevent secondary damage caused by high humid-

ity.

How the Cube works

The Cube refrigerant dehumidifier uses a fan to draw

moist air in and condenses it into water that collects in a

tray and is automatically pumped out through a drain

hose. The unit can be set to operate continuously or the

user may select Humidistat Mode. In Humidistat Mode,

the Cube will turn on and off automatically to maintain

the inlet humidity level the user has selected.

CONTROLS AND OPERATING INSTRUC-

TIONS

Set unit upright

NOTICE: Always store, transport, and use the unit in

a horizontal position. If the unit is ever placed in a

vertical position, return it to the horizontal position

and let it stand for at least 30 minutes before turning

it on.

Positioning a Dehumidifier

For best results, operate your dehumidifiers in an en-

closed area. Close all doors and windows that open to

the outside to maximize water removal efficiency. Place

your dehumidifier away from obstructions, and keep it

away from anything that could block airflow into and out

of the unit. For more information about creating an opti-

mum drying environment, contact Dri-Eaz at

800-932-3030.

Set up drain hose

The Cube condensate pump connects to a plastic drain-

age hose. This hose is equipped with a quick-connect fit-

ting for quick attachment to the provided 20 ft. (6 m)

drain hose. Unwrap the entire hose and place the unat-

tached end in a sink, drain, bucket or outdoors –any-

where that water can drain out safely. If you use a

bucket or other container for water collection, check it

regularly to prevent overflows.

NOTICE: Uncoil and straighten the entire drain hose. Do

not leave any part of the hose coiled and do not place

the end of the hose higher than 20 ft. (6 m) above the

bottom of the unit. Also check for kinks or other obstruc-

tions that might restrict the flow of water. Obstructions

may cause a water backup and result in overflows.

Plug in electrical cord

The Cube should be plugged into a GFCI-protected 115

volt outlet rated for at least 15 amps.

Startup display and normal display modes

When unit is first plugged in to AC power, the control

panel display will briefly cycle through a series of

readouts. This is part of the unit’s self-diagnosis proce-

dure and no user intervention is required.

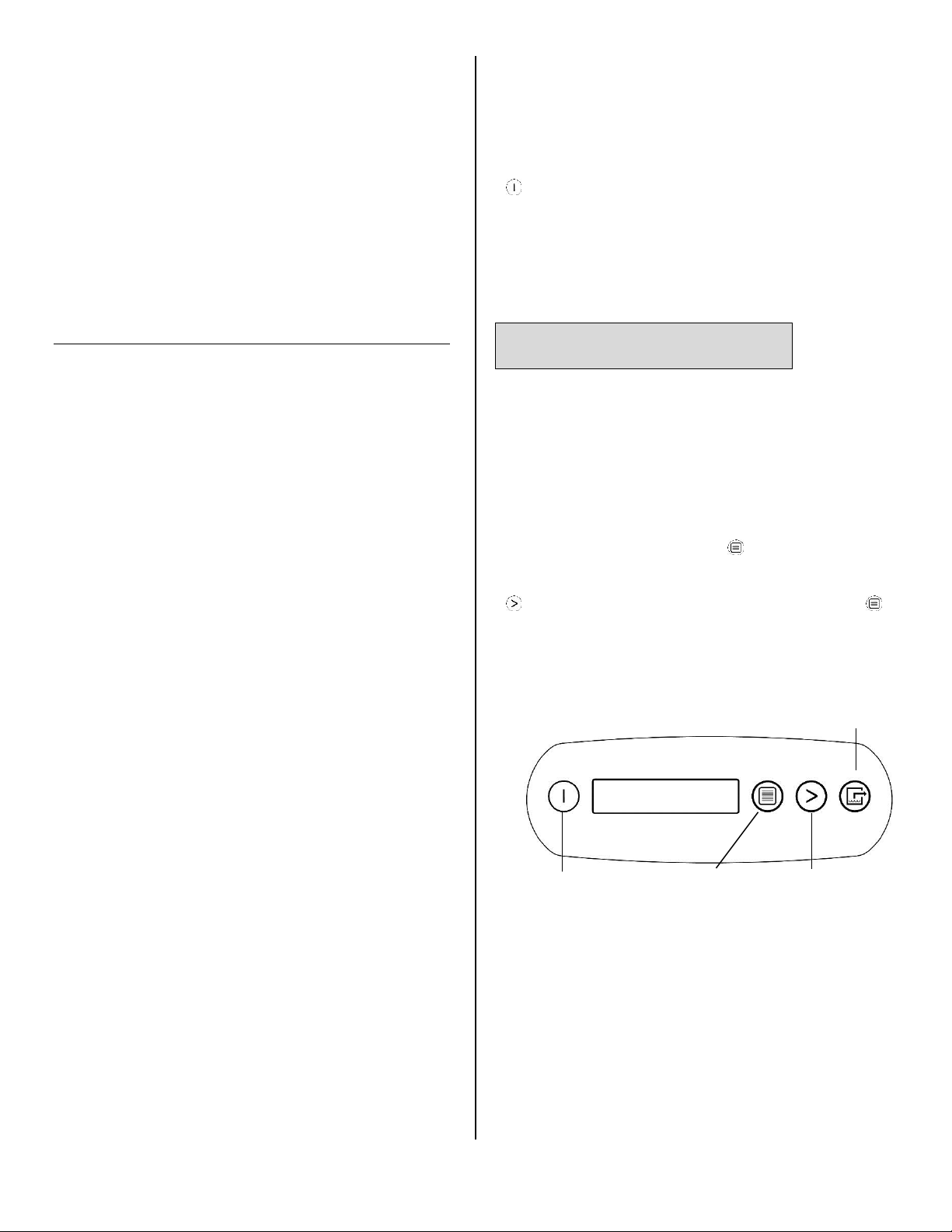

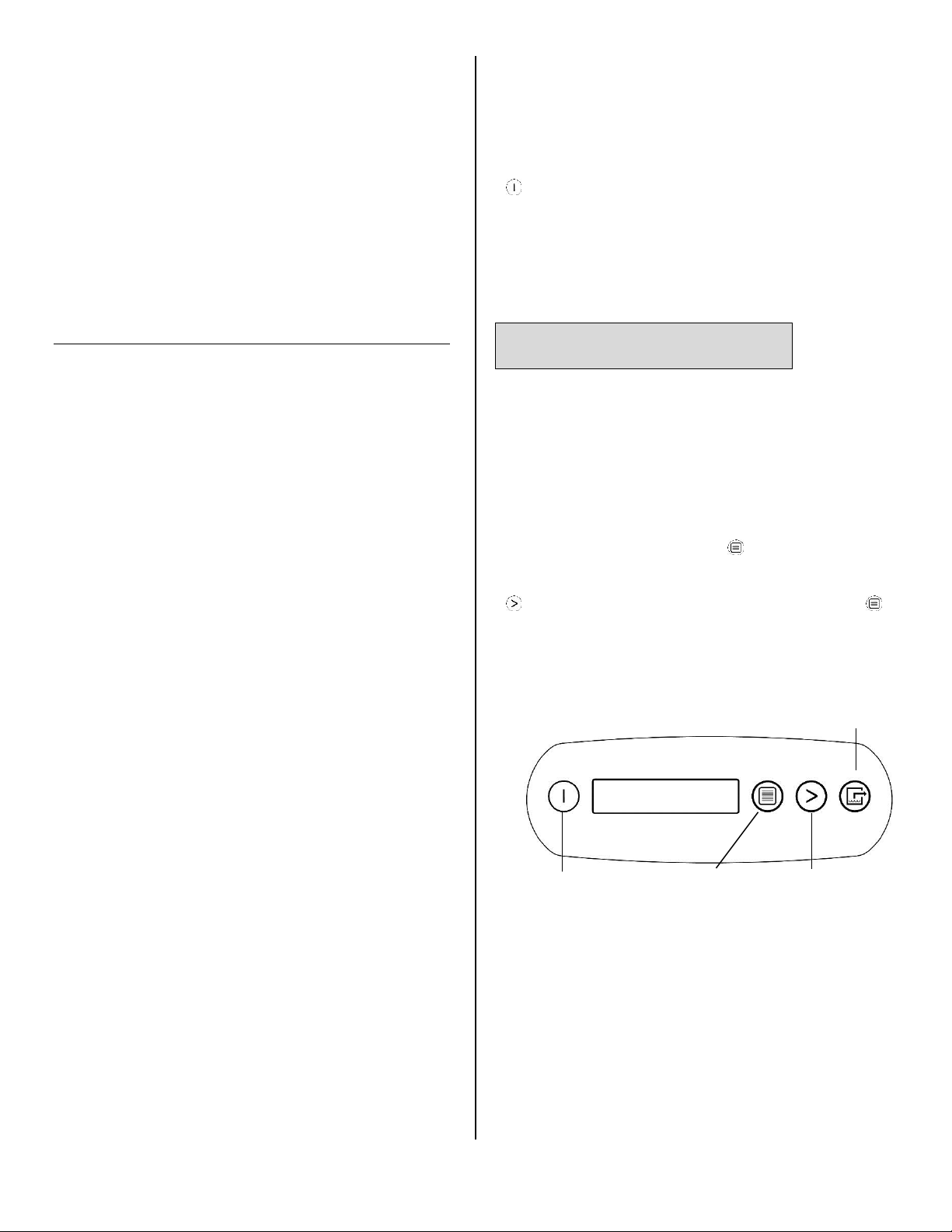

Turn the unit on

The control panel on the Cube dehumidifier has a dis-

play and a touchpad with four keys. Press the

ON/OFF to turn the unit on. The unit will now go

through a compressor delay countdown (up to sixty sec-

onds in duration) and a self-diagnostics process.

Once the compressor delay countdown and self-diag-

nostics are complete, the display will switch to normal

display mode.

UNIT ON 00 HRS

INLET 00°C / INLET 00%

The first line of the display shows the total number of

hours the unit has been in operation. This value may be

reset to zero to track job hours (see “Job Hours Reset”

below). The second line of the display alternates be-

tween inlet temperature and inlet humidity.

User Settings Menu

A number of display settings may be changed by the

user. System information can also be displayed. These

items are accessed by pressing DISPLAY MENU.

Each press of the key will display the next parameter.

When you reach the parameter you wish to adjust, press

MENU SELECTION to increase the value. Press

DISPLAY MENU again to accept the setting and re-start

the display cycle.

Press and release to turn unit

on

or off.

Press to select next item in

menu. Menu item will show

in display.

Press to toggle or select val-

ues in menu displayed.

Press and release to start

purge. Display will count

down seconds remaining until

purge is complete.