Los filtros deben ser sustituidos cada vez que muestren una

visible acumulación de polvillo. Para entornos con un alto

volumen de partículas suspendidas, se recomienda usar dos

prefiltros para así extender la vida del filtro HEPA.

Siempre reemplace el filtro HEPA con prontitud, ni bien se

encienda la Luz de Cambio de Filtro. No intente pasar la

aspiradora y reutilizar el filtro HEPA.

AVISO: Cuando se utiliza el HEPA 500 en proyectos de

remediación, los filtros se deben cambiar y desechar

adecuadamente después de cada trabajo.

Filtros de repuesto disponibles en su distribuidor Dri-Eaz.

MANTENIMIENTO

¡ADVERTENCIA! PELIGRO DE DESCARGA

ELÉCTRICA Desconecte la alimentación eléctrica

antes toda reparación o limpieza.

¡ADVERTENCIA! PELIGRO AL RESPIRAR

Al retirar o sustituir los filtros o al limpiar el filtro del

HEPA 500, utilice siempre un adecuado respirador

aprobado por la NIOSH, y equipo de protección

personal.

Antes de cada uso

1. Verifique si el cable eléctrico presenta daños, y no utilice la

unidad en caso de encontrarlo deshilachado, con cortes, etc.

Póngase en contacto con su distribuidor local de Dri-Eaz para

su reparación.

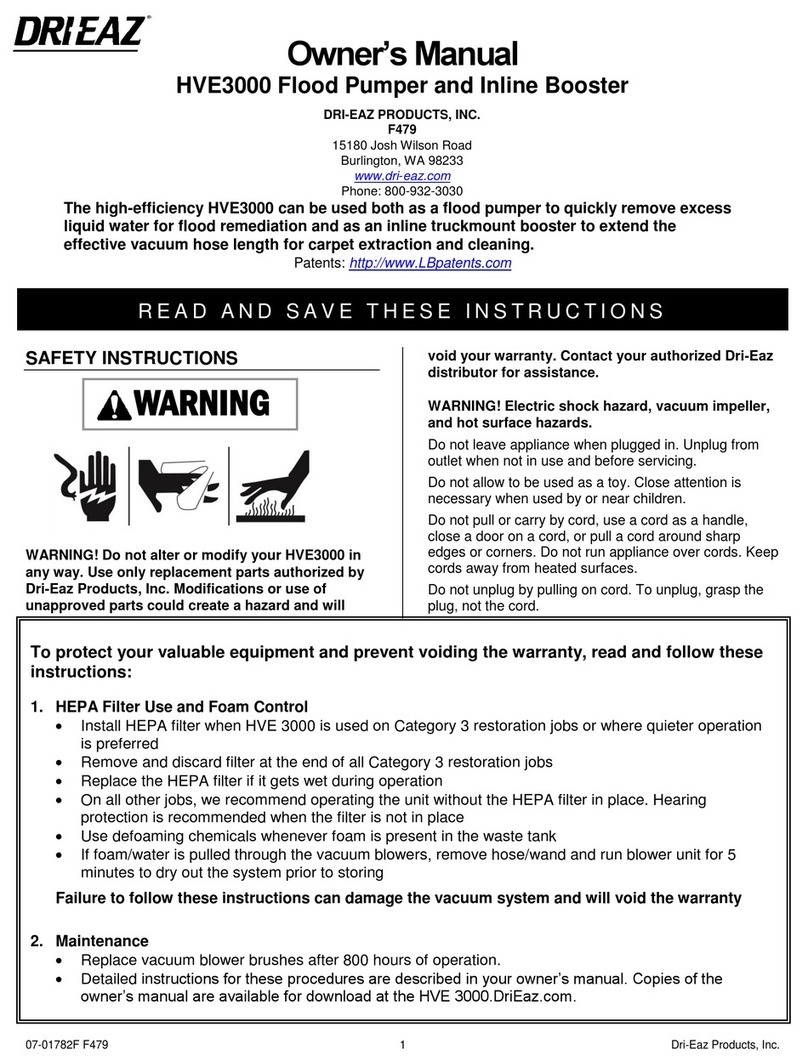

2. Prueba de protección GFCI. Enchufe la unidad y

enciéndala. Ahora presione el botón azul de prueba del GFCI.

Si funciona correctamente, la máquina se apagará y aparecerá

el botón rojo de reinicio. Pulse el botón de reinicio para

reanudar el normal funcionamiento.

Según sea necesario

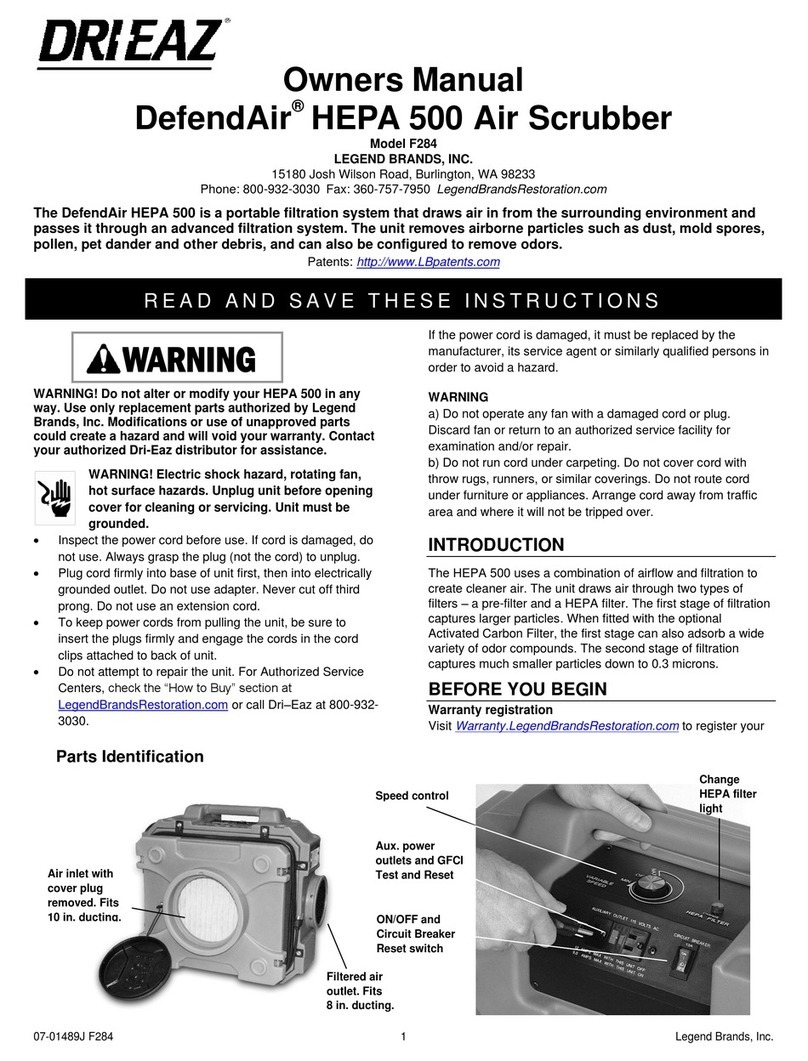

Limpiar la carcasa y el impulsor. Apoye la unidad sobre su

parte posterior y afloje las cuatro abrazaderas de la tapa de

filtros (Fig. 5). Levante la tapa del filtro y quite los prefiltros que

allí se encuentren. Use una llave de 3/8 para

aflojar las 8 tuercas de retención que sujetan

en su lugar el panel de entrada. Deslice las

lengüetas de retención hacia el exterior desde

el centro del panel de entrada y levante el

panel.

Siempre reemplace el filtro HEPA con

prontitud, ni bien se encienda la Luz de

Cambio de Filtro. No intente pasarle la

aspiradora para reutilizar el filtro HEPA.

Filtros

Los prefiltros deben ser inspeccionados

regularmente y reemplazados ni bien se haya

acumulado polvillo en la superficie del filtro de

manera visible.

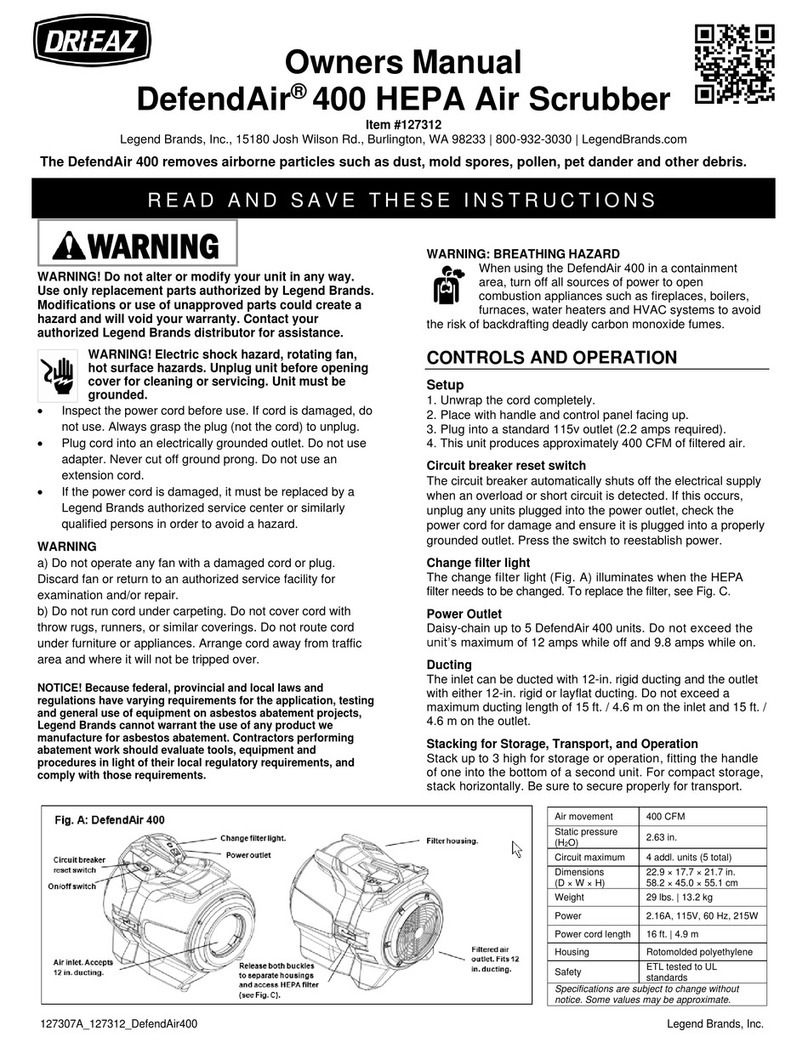

El filtro HEPA debe cambiarse cada vez que

se enciende la luz de cambio de filtro. (Fig. 3)

Consulte "Configuraciones de Filtro HEPA

500", pág. 11, para conocer las combinaciones

disponibles.

Aplicaciones de restauración de daños por agua

Antes de cada uso

Verifique si hay polvillo o suciedad acumulados que pudieran

restringir el flujo de aire a través del filtro de la unidad. Si

hubiera algo visible, cambie el pre-filtro.

Aplicaciones de remediación

• Al cambiar los filtros, utilice equipo de protección personal

aprobado por la NIOSH.

• Cambie los filtros después de cada trabajo de remediación.

• Cambiar el filtro HEPA cuando se encienda la luz del

indicador del filtro (Fig. 3)

• Deseche los filtros usados cumpliendo las normativas

locales.

• Reemplace los prefiltros y filtro HEPA, para así prevenir la

contaminación cruzada.

• Después de cada trabajo y antes de retirar la unidad de la zona de

contaminación, límpiela por completo (aspirar y limpiar con trapo

húmedo, según IICRC S520, 10.11), para así evitar la

contaminación cruzada. Preste especial atención a la zona

alrededor de la entrada de aire. Deje que la unidad se seque antes

de instalar filtros nuevos.

Instrucciones para acceder a los filtros

Para inspeccionar y modificar los prefiltros, apoye la

unidad sobre su parte posterior. Levante y suelte los cuatro

pestillos del panel de salida y levante el panel. Inspeccione

y/o reemplace los prefiltros, según sea necesario.

Tras asegurarse de que los prefiltros se hallan correctamente

colocados, vuelva a poner el panel de salida y enganche los

pestillos. El HEPA 500 ya está listo para volver al ser usado.

Para cambiar el filtro HEPA, apoye la unidad sobre su parte

posterior, luego use una llave de 3/8 para aflojar las 8 tuercas

que sujetan el panel de entrada. Deslice las lengüetas de

retención hacia el exterior desde el centro del panel de entrada

y levante el panel.

Saque el filtro HEPA usado y reemplácelo por uno nuevo. No

limpiar y reutilizar el filtro HEPA.

Después de asegurarse de que el filtro está instalado

correctamente, vuelva a colocar el panel de entrada, deslice

las pestañas en su lugar, y ajuste las tuercas. No ajustar en

exceso. El HEPA 500 ya está listo para volver al ser usado.

Fig. 7: Posiciones de filtrado

filtro HEPA

refiltrado opcional)

(prefiltro)

flujo de aire

07-01489F F284-115V 10 Dri-Eaz Products, Inc.