07-01496D F284-230V UK/EU 3 Legend Brands Europe Holdings Ltd.

microns. See Fig. 4, Filter Positions, and “HEPA 500 Filter

Configurations,” p. 4, for details.

Filters should be replaced whenever they show visible

accumulation of dust. For environments with a high volume of

aerosolized particles, we recommend the use of two prefilters

to extend the life of the HEPA filter.

Always replace the HEPA filter promptly when the Filter

Change Light illuminates. Do not attempt to vacuum and reuse

the HEPA filter.

NOTICE: When using the HEPA 500 on remediation

projects, the filters should be changed and properly

disposed of after every job.

Replacement filters are available from your Dri-Eaz

distributor.

MAINTENANCE

WARNING! ELECTRIC SHOCK HAZARD.

Disconnect from electrical supply prior to servicing

or cleaning.

WARNING! BREATHING HAZARD. Always wear

an appropriate NIOSH-approved respirator and

personal protective equipment when removing or

replacing filters, or when cleaning the HEPA 500.

Before each use

1. Inspect the electrical cord for damage, and do not use the

unit if you find any fraying, cuts, etc. Contact your local Dri-Eaz

distributor for service.

As Needed

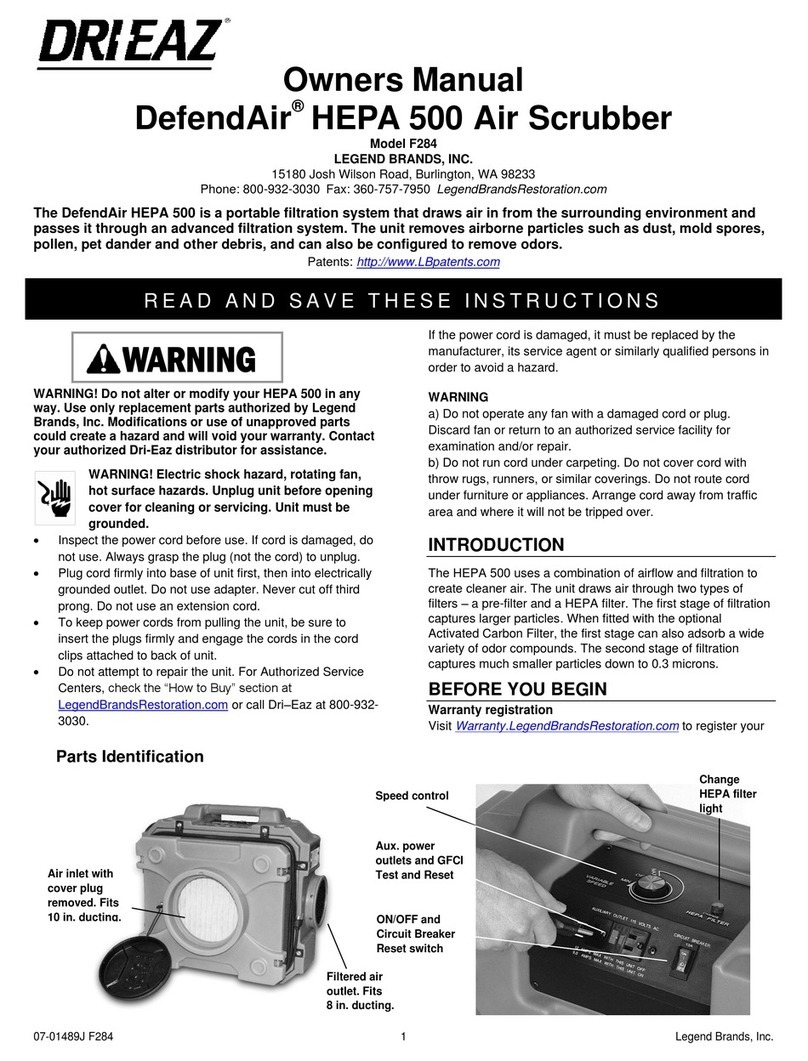

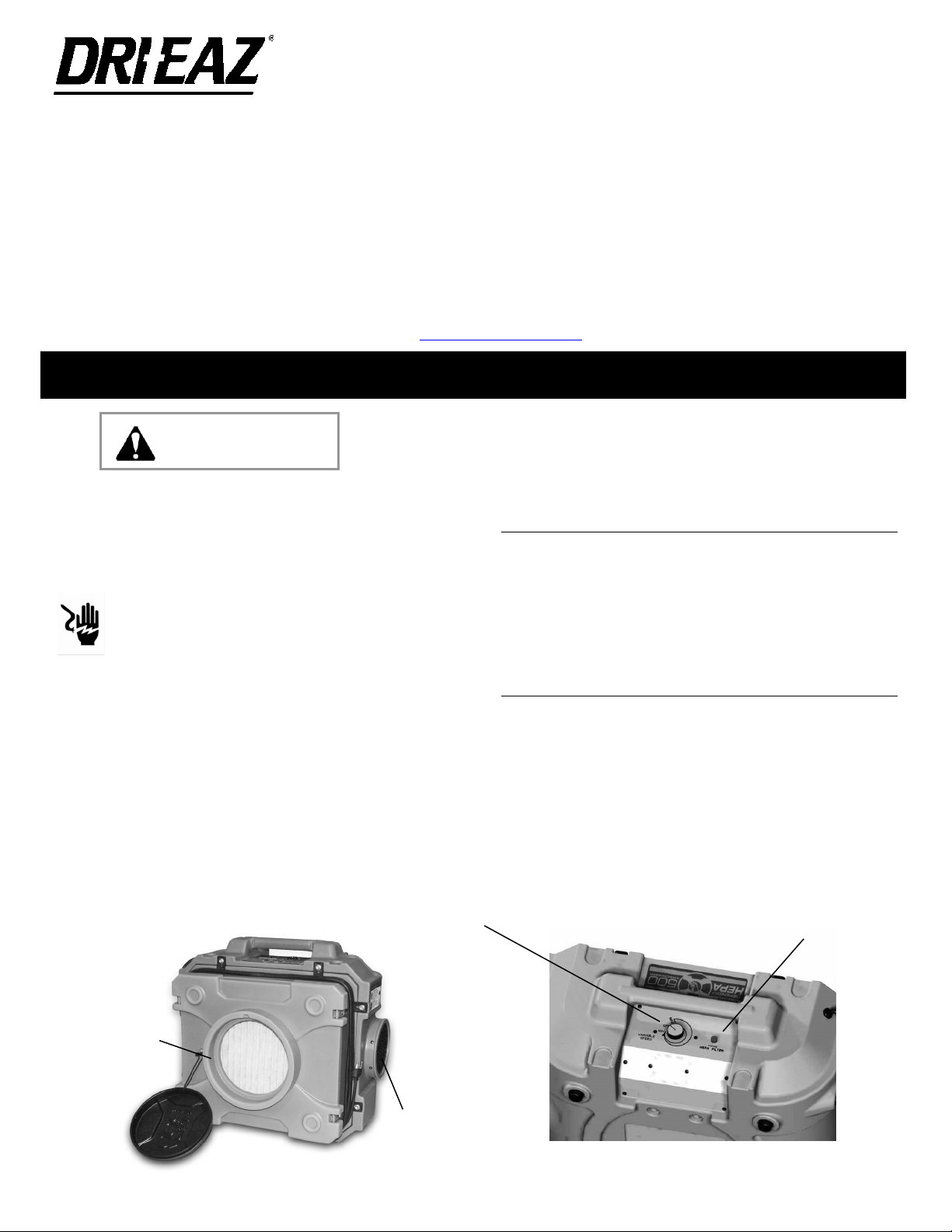

Clean housing and impeller. Lay the the unit on its back and

loosen the four filter cover clamps (Fig. 2). Lift off the filter

cover and remove any prefilters present. Use a 3/8 in. wrench

to loosen the 8 retaining tab nuts holding the inlet panel in

place. Slide the retaining tabs outward away from the center of

the inlet panel, and lift off the inlet panel.

Always replace the HEPA filter promptly

when the Filter Change Light illuminates. Do

not attempt to vacuum and reuse the HEPA

filter.

Filters

The prefilters should be inspected regularly

and changed whenever dust has visibly

accumulated on the filter surface.

The HEPA filter should be changed

whenever the change filter light comes on.

See “HEPA 500 Filter Configurations,” p. 4,

for the available filter combinations.

Water damage restoration

applications

Before each use

Look for accumulated dust and dirt that

could restrict airflow through the filter into

the unit. If any is visible, change out the pre-

filter.

Remediation applications

• Wear NIOSH-approved protective gear when changing filters.

• Change filters after every remediation job.

• Change HEPA filter when the filter indicator light comes on.

• Dispose of used filters according to local regulations.

• Replace both the prefilters and HEPA filter to prevent cross-

contamination.

• Clean the unit thoroughly (vacuum and damp wipe per IICRC

S520, 10.11) after each job before removing it from the

containment area to avoid cross-contamination. Pay particular

attention to the area around the air intake. Let the unit dry

before installing clean filters.

Filter access instructions

To inspect and change the prefilters, lay the unit flat on its

back. Lift and release the four latches on the outlet panel and

lift off the panel. Inspect and/or replace the prefilters as

necessary.

After ensuring that the prefilter(s) are properly seated, replace

the outlet panel, and re-engage the latches. The HEPA 500 is

now ready to return to service.

To change the HEPA filter, lay the unit flat on its back, then

use a 3/8 in. wrench to loosen the 8 retaining tab nuts holding

the inlet panel in place. Slide the retaining tabs outward, away

from the center of the inlet panel, and lift off the inlet panel.

Lift out the used HEPA filter and replace it with a new one. Do

not clean and reuse the HEPA filter.

After making sure that the filter is properly seated, replace the

inlet panel, slide the tabs back into place, and tighten the nuts.

Do not overtighten. The HEPA 500 is now ready to return to

service.

About DOP first-pass filtration efficiency

DOP (Dispersed Oil Particulate) first-pass efficiency refers to a

standard procedure for testing the effectiveness of HEPA

filtration. The DOP test introduces a dense cloud of extremely

fine particulates into the filter under controlled conditions. DOP

verification is required in certain settings.

The addition of the DOP filter (F415) makes the HEPA 500 a

high efficiency three-stage air filtration unit suitable for any job

housing

second refilter)

(prefilter)