LARATION OF CONFORMITY……………...……………………………………..………….1

2.- SYSTEM DESCRIPTION………………...….…..……………………………………….…………..2

SAFETY INSTRUCTIONS………………………..…………………………………….…….………3

3.1.- WHAT YOU MUST DO…………………………..………………………………………………...3

3.2.- WHAT YOU MUST NOT DO……………………..………………………………………………..3

4.- INSTALLATION…………………………………… …………………………………….………….4

4.1.- THE CB60 BATTERY CHARGER……………… ..………………………………….…………..4

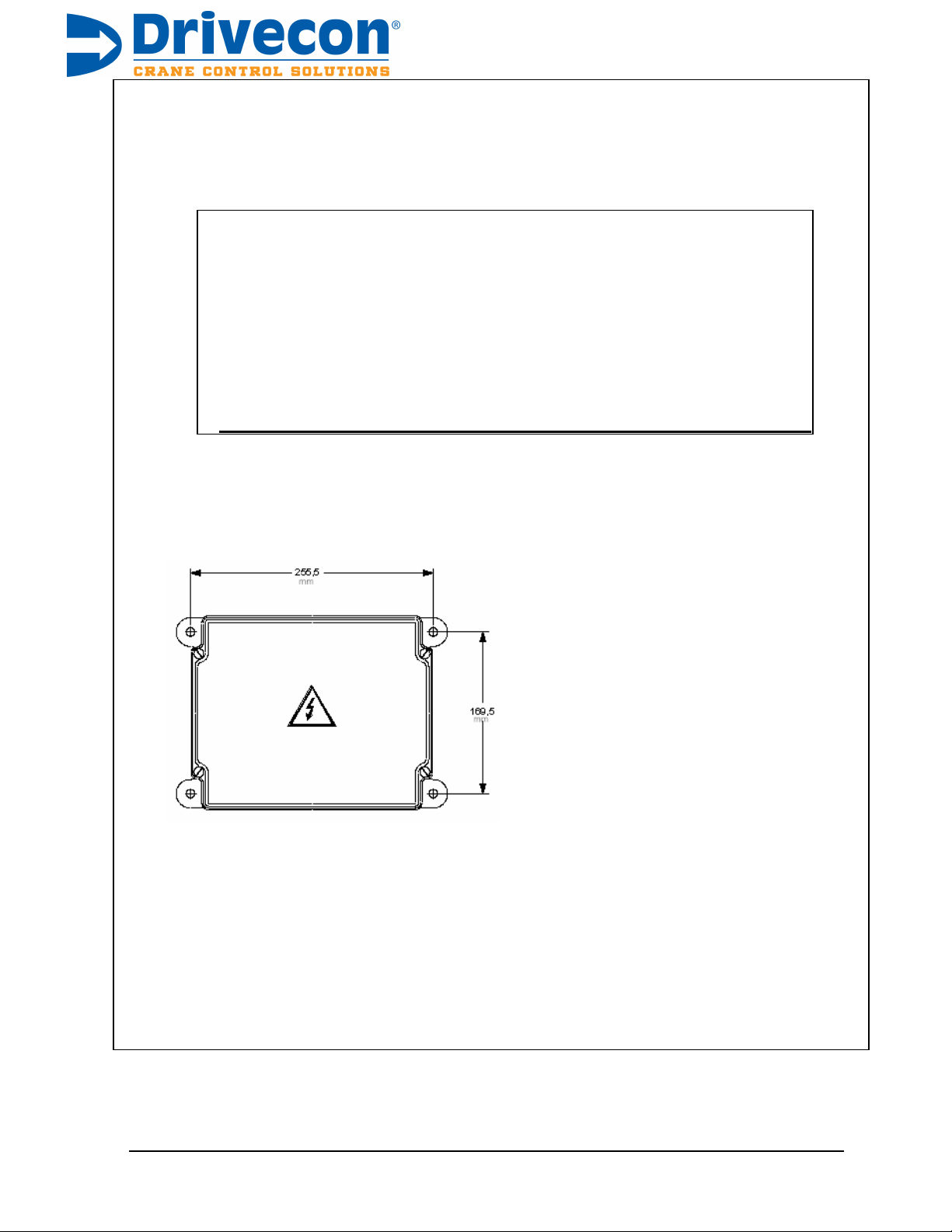

4.2.- RECEIVER…………………………………………..……………………………………...………5

4.3.- STARTING UP ………………………………………..………………………………………… .7

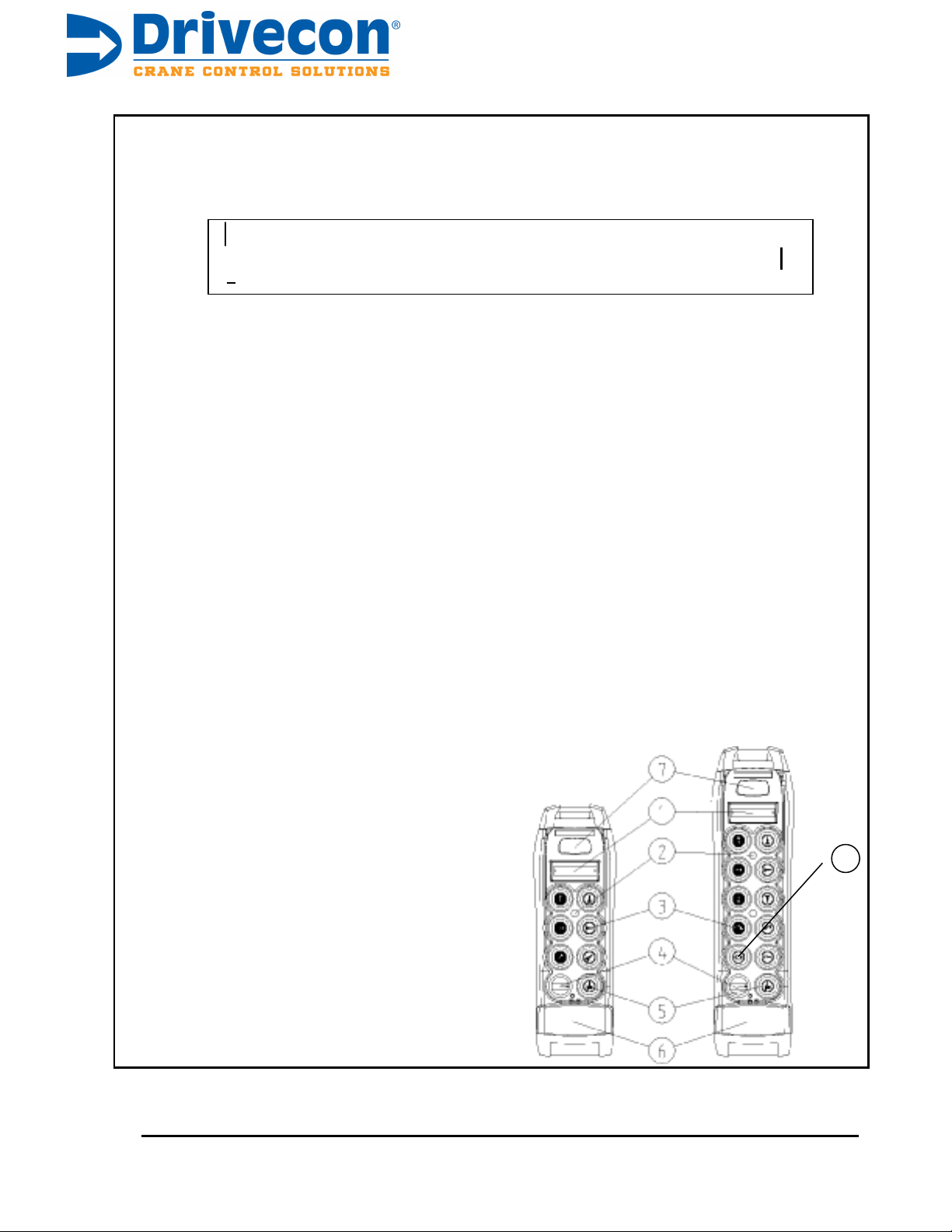

5.- USING THE RADIO..…………………………………. ….…………………………………………9

TANDEM OPERATION………….………………………..……………………………………......10

6.1 - INTRODUCTION...............................................................................................................10

6.2 - SYSTEMS WITH 1 MASTER TRANSMITTER..................................................................11

6.3 - SYSTEMS WITH 2 MASTER TRANSMTTERS................................................................12

7.- FIRST COME - FIRST SERVED OPERATION......................................................................13

7.1 - INTRODUCTION................................................................................................................13

7.2 - SYSTEMS WITH 2 TRANSMITTERS................................................................................14

8.- PITCH & CATCH OPERATION.............................................................................................15

8.1 - INTRODUCTION.................................... ..........................................................................15

8.2 - SYSTEMS WITH 2 TRANSMITTERS................................................................................16

9.- RANGE LIMITER OPERATION.............................................................................................17

9.1 SYSTEM DESCRIPTION....................................................................................................17

9.2 - INFRARED SENSOR..........................................................................................................17

9.3 - INFRARED TRANSMITTER ............................................................................................19

9.4 - INSTALLATION...................................................................................................................20

9.5 - TECHNICAL CHARACTERICS OF THE LA70...................................................................21

10.- MAINTENANCE.....................................................................................................................22

10.1 -PRECAUTIONS.................................................................................................................22

10.2 -FAULT FINDING............................................... ................................................................22

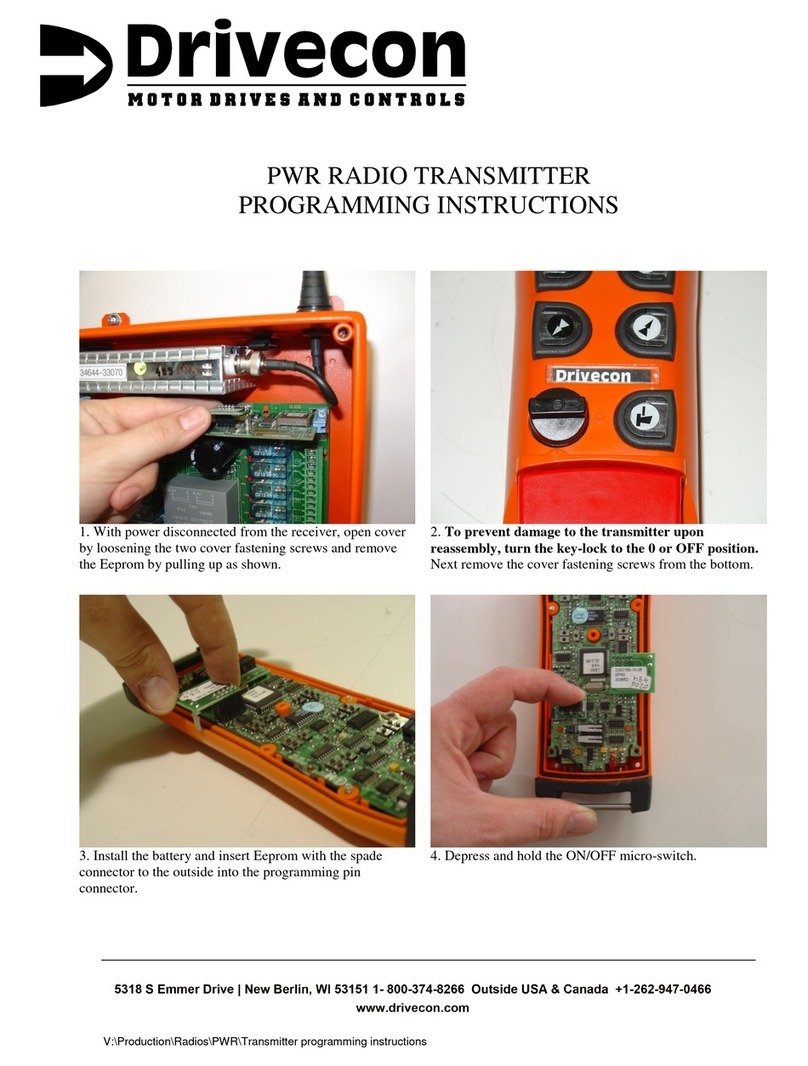

APPENDIX A - PROGRAMMING A SPARE TRANSMITTER…………………………………...24

STANDARD WIRING DIAGRAMS....

.................................................................25