VPT10-H HART

®

PRESSURE TRANSMITTER INSTALLATION, OPERATION, CONFIGURATION AND MAINTENANCE MANUAL

____________________________________________________________________________________________________________________________

3

SUMMARY

1EQUIPMENT DESCRIPTION..................................................................................................................................6

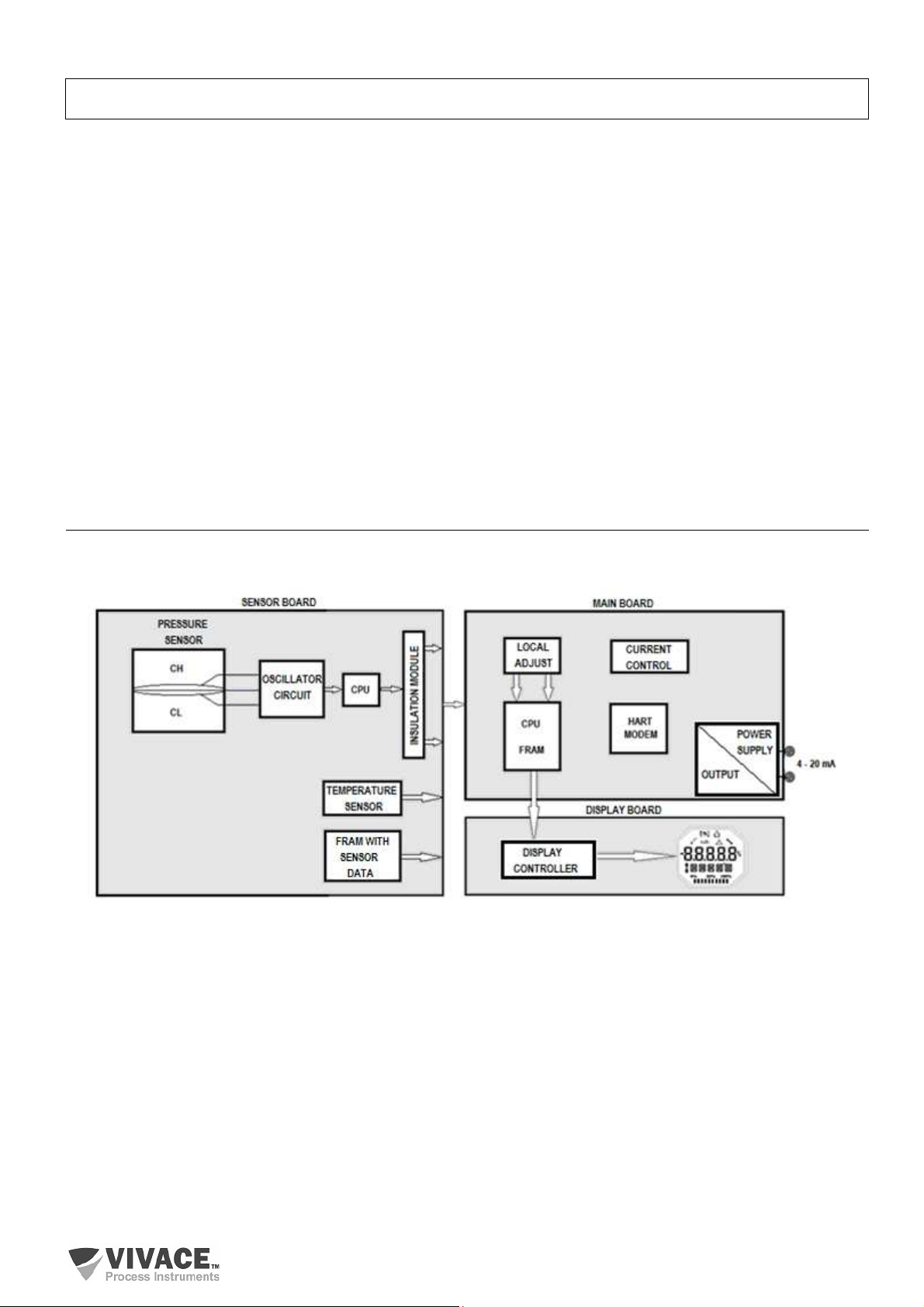

1.1. BLOCK DIAGRAM.........................................................................................................................................6

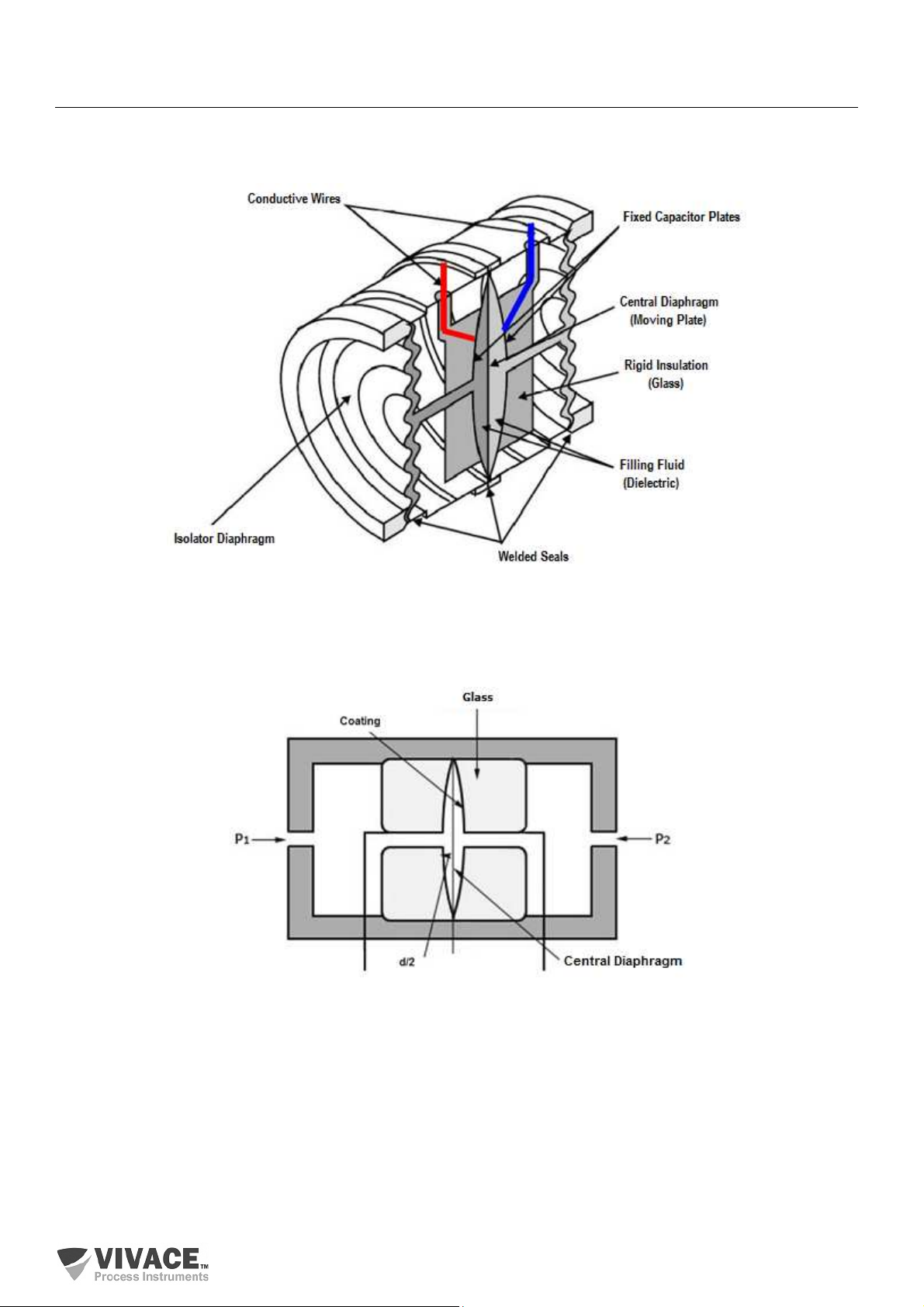

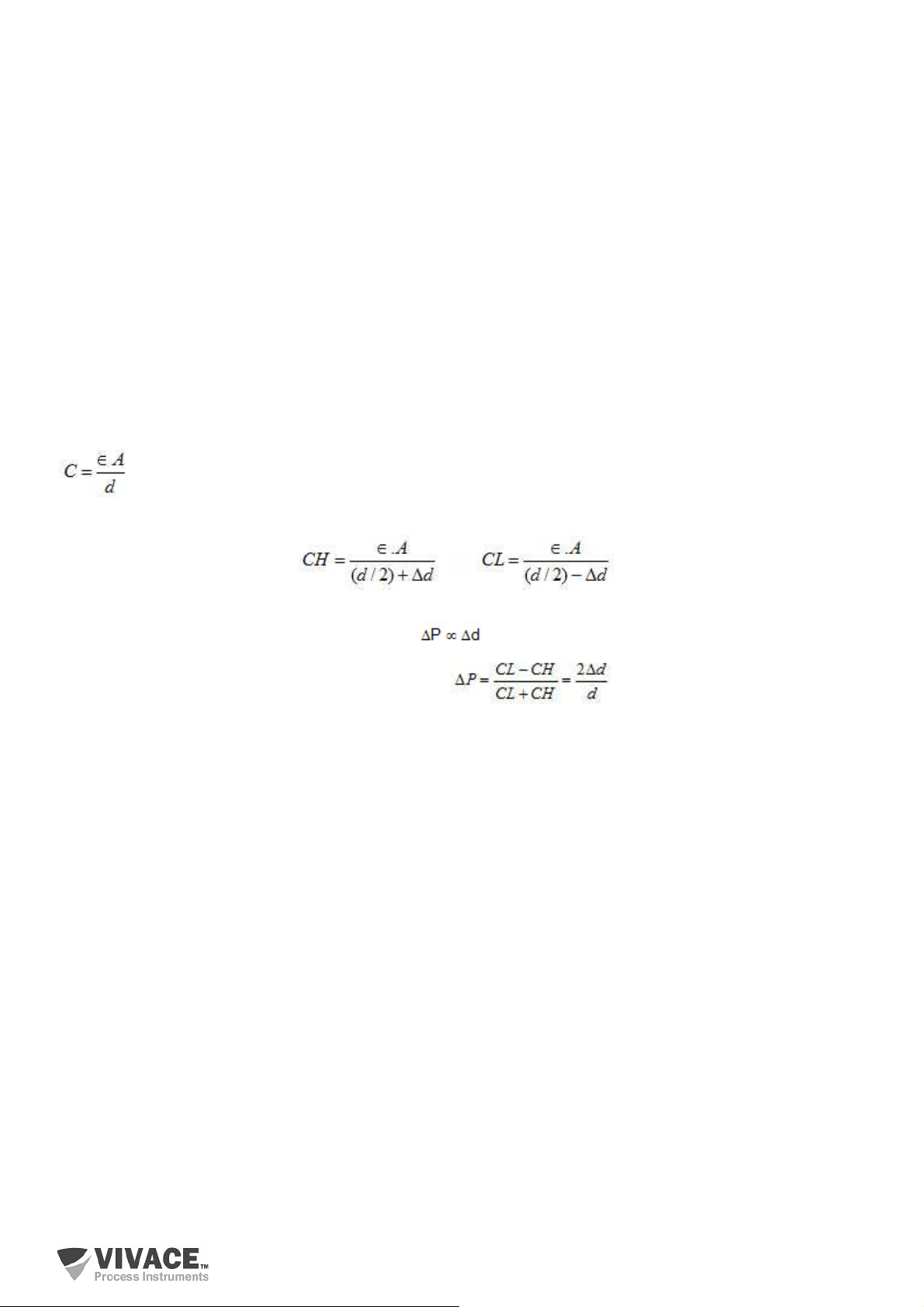

1.2. CAPACITIVE SENSOR .................................................................................................................................7

1.3. OPERATING PRINCIPLE..............................................................................................................................9

2INSTALLATION ....................................................................................................................................................10

2.1. MECHANICAL ASSEMBLY.........................................................................................................................11

2.2. ELECTRICAL CONNECTION .....................................................................................................................14

3CONFIGURATION ................................................................................................................................................16

3.1. LOCAL CONFIGURATION..........................................................................................................................16

3.2. JUMPER CONFIGURATION FOR LOCAL ADJUST AND WRITE PROTECTION ....................................17

3.3. LIQUID CRYSTAL DISPLAY (LCD) ............................................................................................................18

3.4. HART

®

PROGRAMMER..............................................................................................................................18

3.5. LOCAL ADJUST CONFIGURATION TREE ................................................................................................20

3.6. HART CONFIGURATOR PROGRAMMING TREE .....................................................................................21

3.7. CALIBRATION .............................................................................................................................................25

3.8. DIAGNOSIS .................................................................................................................................................26

3.9. FDT/DTM CONFIGURATION......................................................................................................................28

4MAINTENANCE ....................................................................................................................................................29

4.1. ASSEMBLY AND DISASSEMBLY PROCEDURES....................................................................................29

4.2. SPARE PARTS............................................................................................................................................30

5CERTIFICATION ...................................................................................................................................................32

6TECHNICAL CHARACTERISTICS ......................................................................................................................33

6.1. IDENTIFICATION ........................................................................................................................................33

6.2. TECHNICAL SPECIFICATION....................................................................................................................34

6.3. ORDERING CODE ......................................................................................................................................35

7WARRANTY..........................................................................................................................................................38

7.1. GENERAL CONDITIONS ............................................................................................................................38

7.2. WARRANTY PERIOD .................................................................................................................................38

APPENDIX ....................................................................................................................................................................39