3

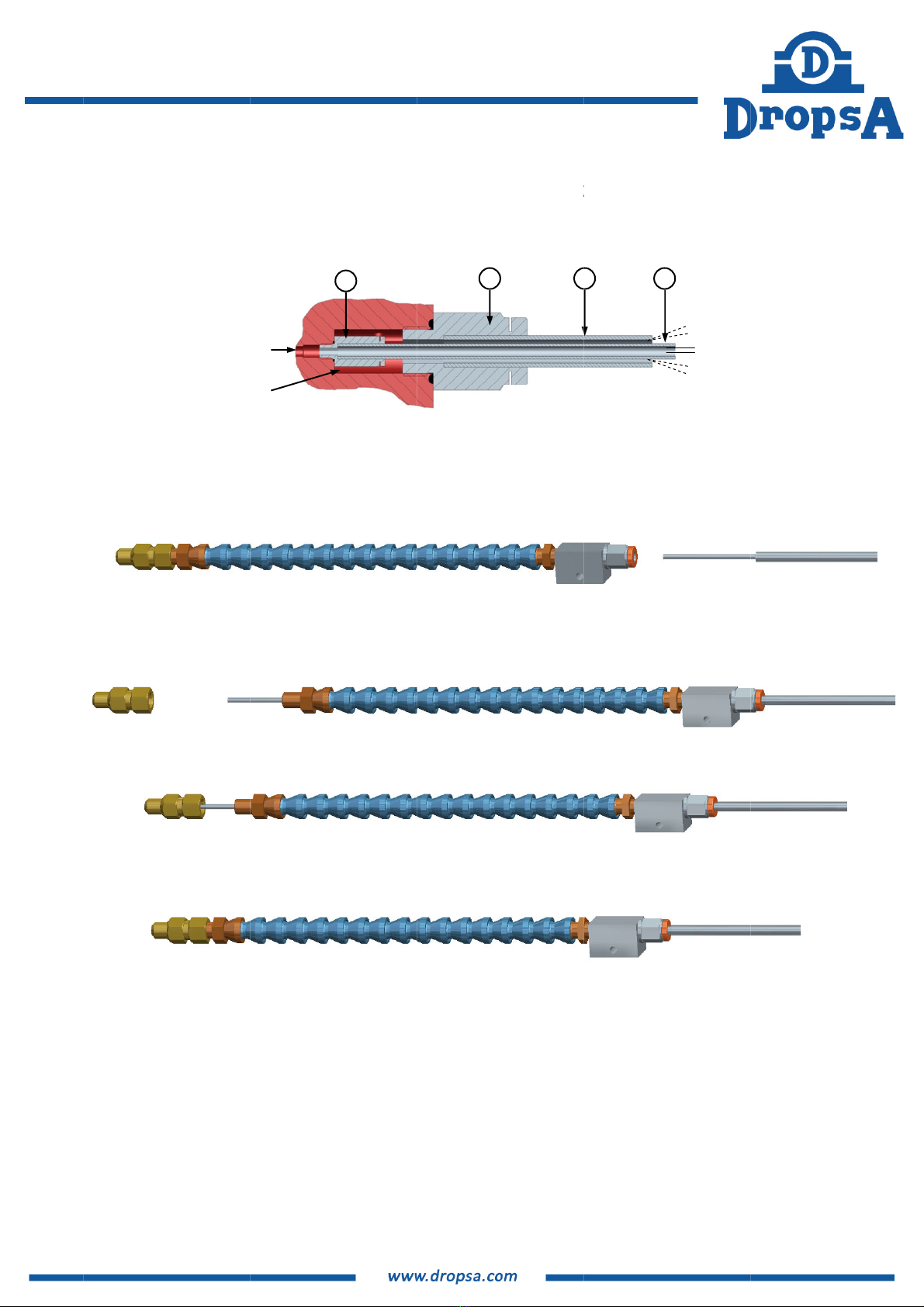

Spraynozzles

When traditional pipes are used, the air and oil are already mixed when they arrive at the nozzle.

If coaxial pipes are used, the nozzle mixes the air and oil at the point to be lubricated. The lubricant is atomised in

minuscule particles by the air flow that passes in front of the oil outlet hole.

The geometry of the nozzle is designed based on the type of spray to be obtained (conic, blade-shaped, etc.).

Advantages

Easy to install on the machine

Reduction in tool wear

Improved surface finish on the part

No lubricant residuals left on the part when the work is complete

The nozzles do not drip after being turned off

Large spray range (up to 300 mm)

Greater safety and environmental hygiene at the workplace

Application

Machine tools

Machines for cutting and bending plate

Steelworks

3.MACHINEIDENTIFICATION

There is a plate on the side of the unit that displays the product code, the power supply voltages and the basic

characteristics.

4.TECHNICALSPECIFICATIONS

TECHNICAL SPECIFICATIONS

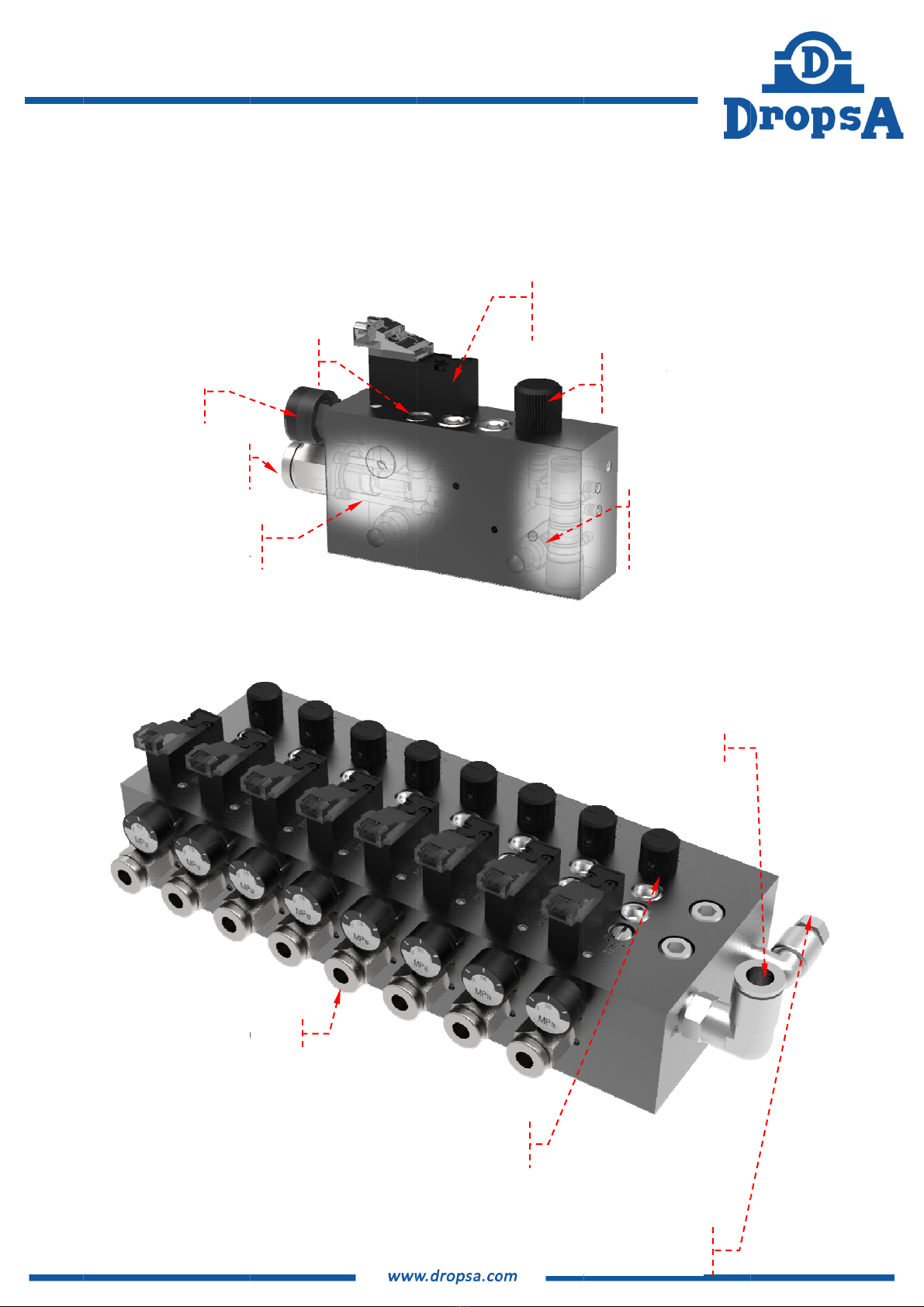

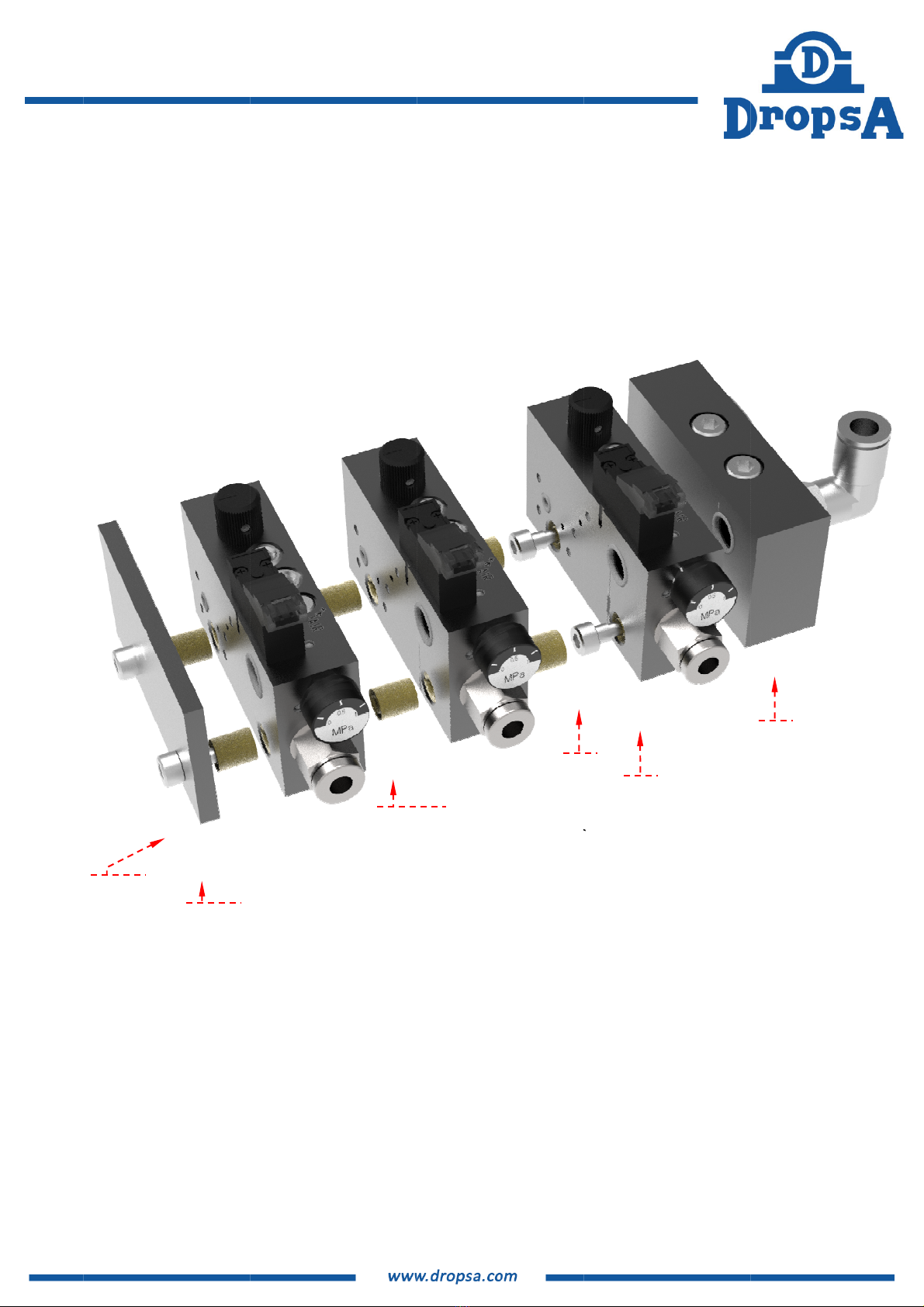

Pumping system External pump

Maximum number of modules 8

Maximum Oil inlet pressure 2,5:1 in relation with air inlet pressure

Air inlet pressure 4bar ÷ 7bar [87psi ÷ 101,5psi]

Maximum air consumption at the outlet ~50Nl/min (per module)

Air inlet pipe

8mm

Oil inlet pipe Ø6mm

Air outlet pipe Ø6mm

Oil outlet pipe Ø3mm

Oil flow rate per element

PRO

0,1 ÷ 2,7 cc/min (Oil 10cSt)

0 ÷ 1 cc/min (Oil 32cSt)

0 ÷ 0,2 cc/min (Oil 100cSt)

BASE

0,3 ÷ 8 cc/min (Oil 10cSt)

0,1 ÷ 3 cc/min (Oil 32cSt)

0 ÷ 0,6 cc/min (Oil 100cSt)

CART

cc/min = (P x 8,16)/

P = Operating pressure in [bar]

V = viscosity [Engler] at operating temperature

Lubricant 10cSt ÷ 100cSt

Protection grade of module “-i”Standard IP 0

On request (special) IP 65

Element solenoid valve power supply 24Vd

Operating temperature +5°C ÷ +50°

Storage temperature -10°C ÷ +80°

Max relative humidity without operating condensate 90%

Sound level pressure < 70 db (A)