•Important: When verifying rotor speed, make certain that all carriers are installed

in the rotor.

•No calibration adjustment of speed can be made, only a verification of rotor speed.

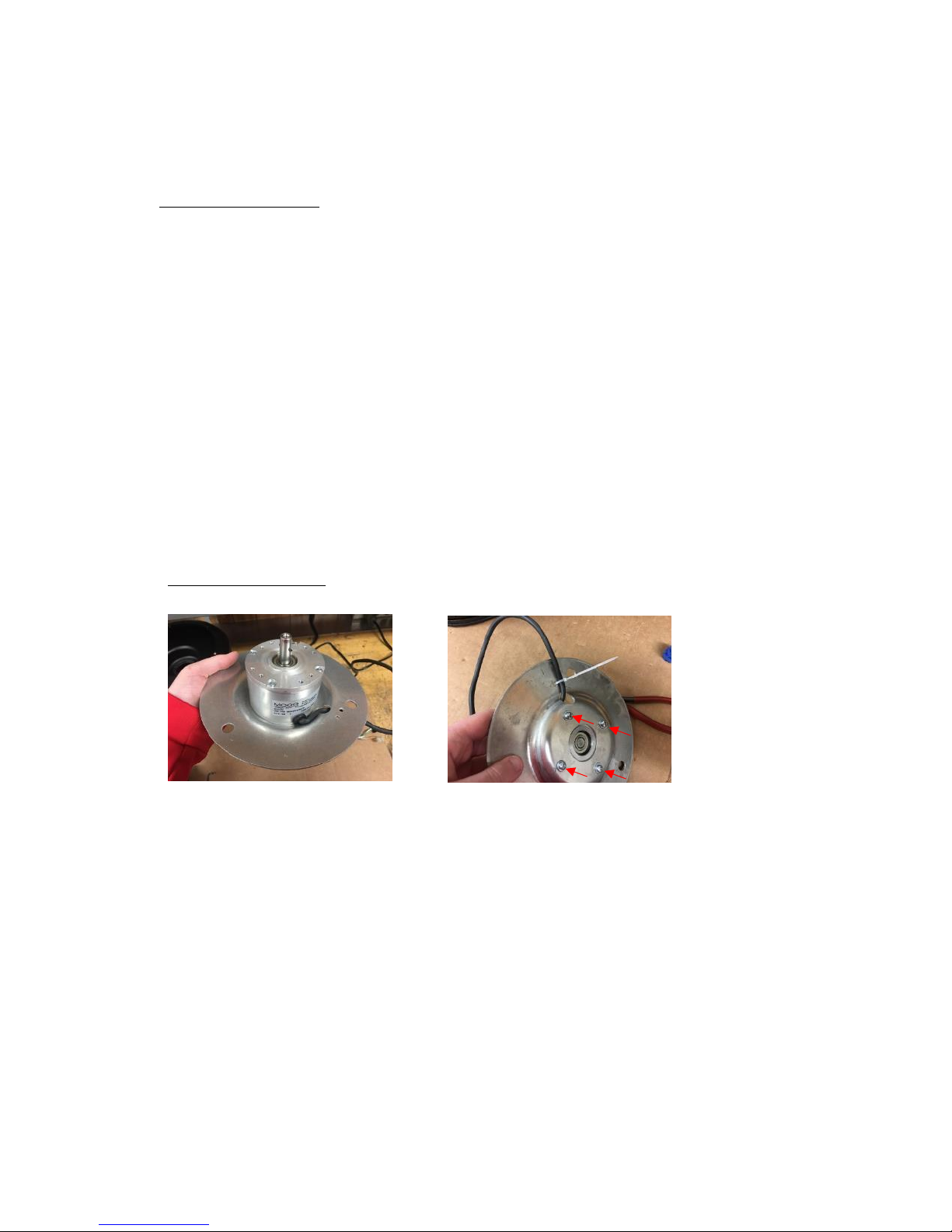

7.6. Removing the Cabinet (Upper Housing)

•There are eight screws that fasten the centrifuge cabinet to the base.

•Begin by unplugging the centrifuge.

•Use a 3/32 hex key to remove the cabinet screws (three on left and right sides, two

in the rear)

•The cabinet control panel is attached to the base internally with cable harnesses.

Be careful not to stress the cables when removing the cabinet.

•Stand directly in front of the centrifuge and lift the cabinet straight up and off the

base, setting it down on its right side.

•Gently remove the power supply and motor harnesses from the PCB.

7.7. Replacing the Lid Lock Assembly

•The lid tray assembly is accessible once the cabinet has been removed.

•Gently remove the lid tray wire harness from the PCB.

•The lid tray assembly is held in place with two #6 Nylok nuts. Use a 5/16” nut driver

to remove the nuts. The tray will slide off the threaded studs.

•To install the lid tray, slide it onto the studs, and secure it with two #6 Nylok nuts,

hand tight.

•Complete the installation by gently plugging the wire harness into the PCB header

‘J4’. The header and connector are keyed for proper orientation.

7.8. Replacing the PCB

•The PCB is accessible once the cabinet has been removed. Make certain that all

wire harnesses have been disconnected. Use standard precautions for handling

static sensitive components.

•The PCB is held in place with six #6 Nylok nuts and plastic insulator washers. Use a

5/16” nut driver to remove the nuts. The PCB and washers are now free to slide off

the threaded studs.

•Beneath the PCB are six plastic standoffs. If they are crushed, replace them before

reassembly.

•To install the PCB, make certain that six plastic standoffs are present on the control

panel studs.

•Slide the board onto the studs

•Install six plastic washers onto the studs securing the circuit card.

•The six nuts should be tightened only until the buttons on the control panel click

when pressed –do not over tighten. Each nut sets the height of a separate control

panel button. Too low, and they cannot be actuated, too high and they jam against