6

larger models should be used with a floor stand due to their size and weight. The ideal working

height of the press will vary depending on the operator. We suggest a height of 28 to 31 inches

(700 to 790 mm). It is critical that the lid of the press is able to open fully. Please be absolutely

sure that nothing interferes with this!

For proper operation, it is very important that the press be flat and level. The best way to verify

this is to use a carpenter’s (bubble) level. If one corner of the unit is at a different height from the

others, it may be difficult to achieve a proper vacuum. For best results, we recommend that the

press be located away from air conditioning vents, fans

and other sources of moving air.

Unpacking: Carefully inspect the vacuum press for

possible shipping damage. If any is discovered, please

contact our Customer Service Department immediately. If

you are using a floor stand, unpack and assemble it

using the instructions provided. Remove the vacuum

press from the shipping carton and place it on the stand

or table. Leave room to make connections to the rear of

the unit.

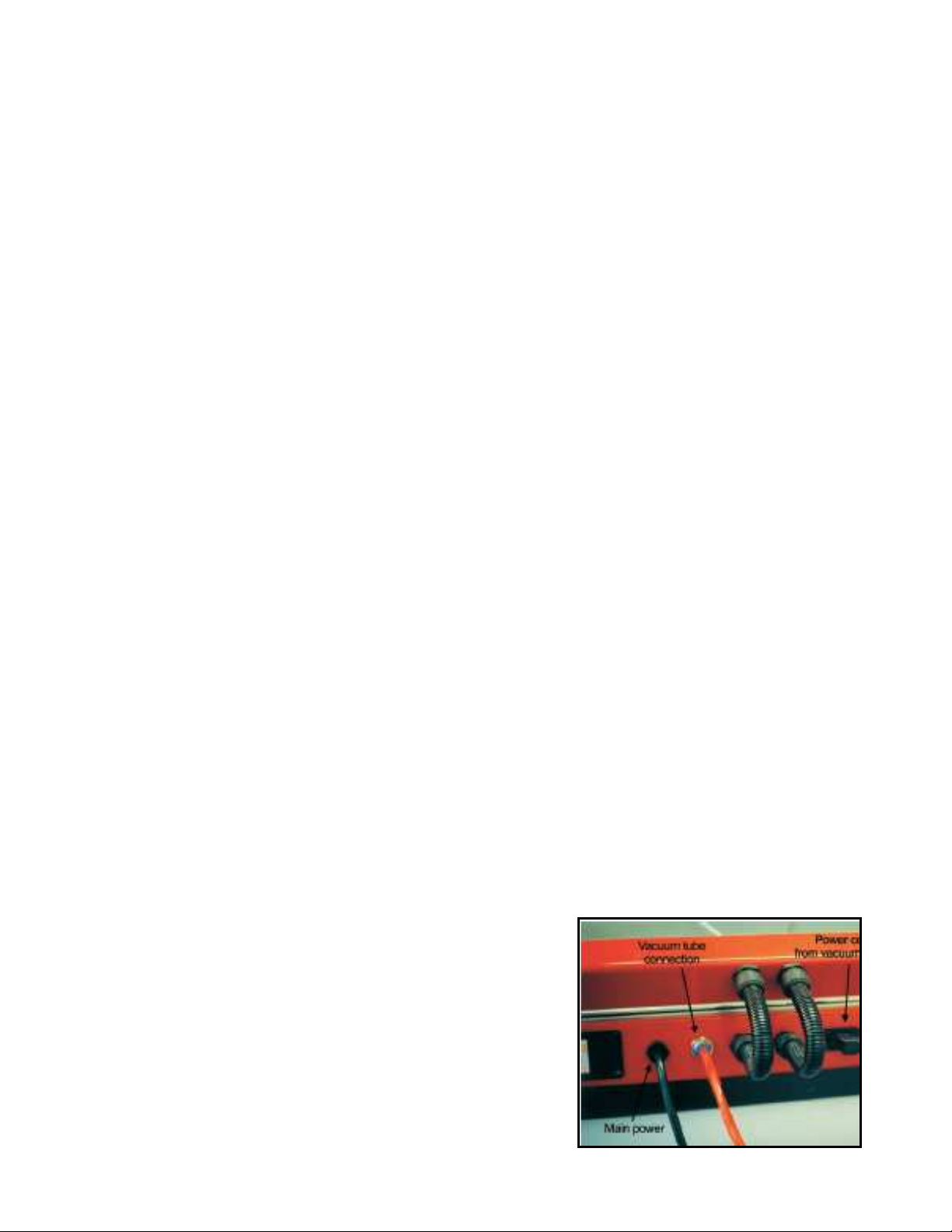

Unpack and remove the vacuum pump from its box. The

pump should be placed on or near the floor. There are

suction cups on the bottom of the pump to help keep it in

place, since the pump vibrates during operation. The

pump will become warm during extended usage. If the

equipment is going to be used in a high-volume production

environment, please allow for adequate ventilation of the

area where the pump is located.

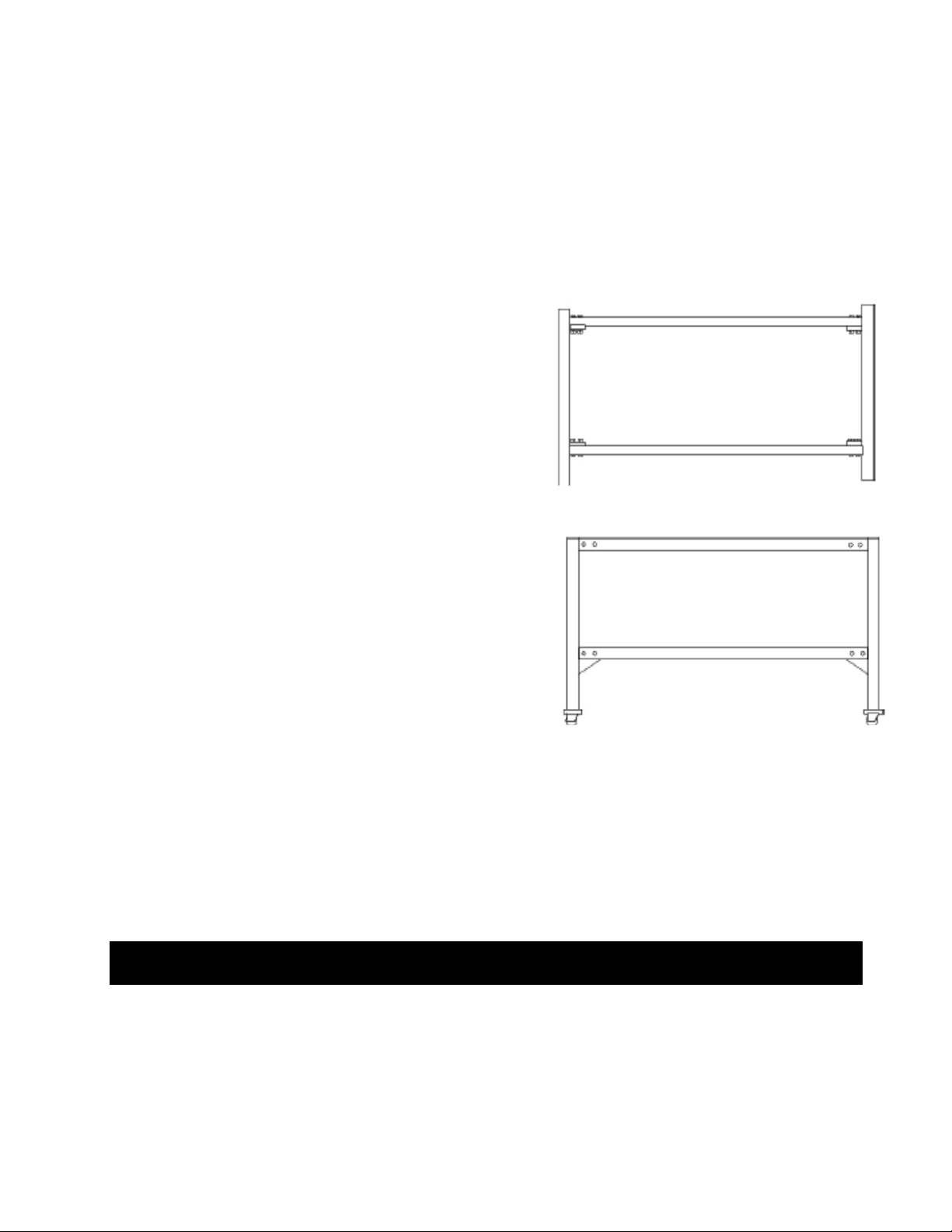

Stand Assembly (Model HPG560 Only)

Loosely fit the four tie bars to the ends of the stand (Illustration 4B), using the 16 M10 x 50 bolts,

32 x M10 plain washers and 16 M10 nuts. Tighten all nuts and bolts. Move stand into final position

and ensure that it is level by using the leveling spacers. The stand may be leveled by supporting

the low corner of the stand on the tie bar and removing the wheel. The leveling spacers can then

be inserted between the stand and the wheel assembly and the wheel assembly re-bolted to the

stand. Lower the stand back to the ground and re-check to make sure it is level.

WARNING: THIS OPERATION SHOULD BE CARRIED OUT BY A MINIMUM OF SIX PEOPLE!

The correct functioning of your vacuum press cannot be guaranteed if the press is not

mounted securely onto the stand and the press leveled.

Mount the Press onto the Stand (Model HPG560 Only)

Remove the divider panels from the crate. Remove the screws from the side pieces of crate.

Remove protective packaging from the press. HOLDING THE FRONT AND REAR OF THE

PRESS ONLY AND NOT WITHIN 75 mm OR 3 INCHES OF THE ENDS, lift the press from the

Illustration 4B: Stand Assembly

Illustration 4C: Stand Assembly