3

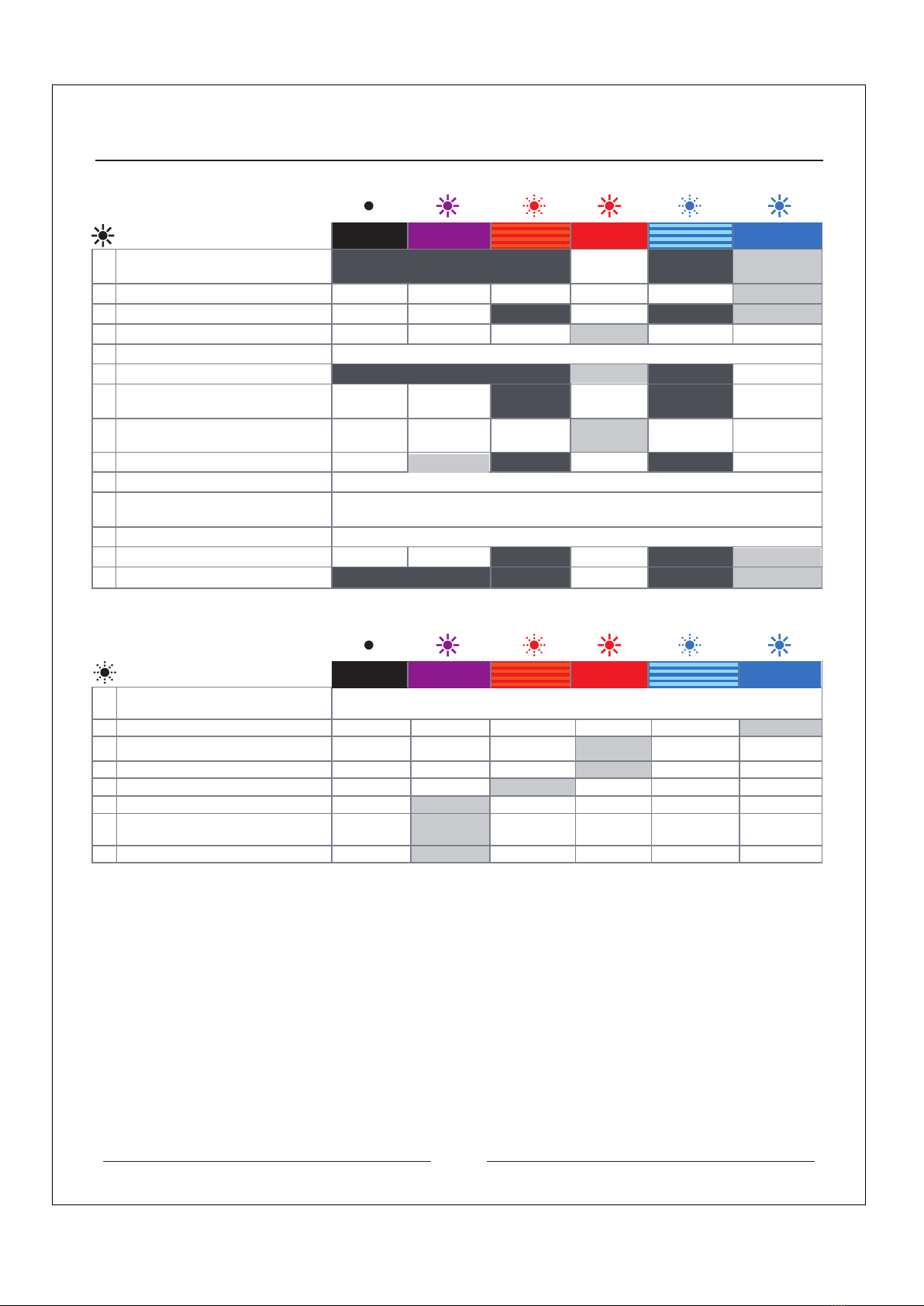

Warning Label Legend

Safety Precautions and Warning

Pre-flight check

Statement

FORBIDDEN

FORBIDDEN

Do not attempt under any circumstances.

WARNING

Mishandling due to failure to follow these instructions may result in danage or injury.

CAUTION

RC helicopter is controlled by radio signals. It may be interfered by other radio signals during operation.

These interference may cause the helicopter lose control.

Mishandling due to failure to follow these instructions may result in danger.

WARNING

An RC Helicopter is not a toy! For avoiding accidents and damage, please operate the helicopter properly.

Since the consumer have purchased the helicopter, they should take all the risks in the usage. To ensure

your safety, if you are a beginner, you are recommended to consult or get assistance from experienced RC

modelers or your local hobby stores.

You should buy the authorized DTS accessories when you choosing the accessories. Otherwise, some

RC functions may not be matched or function unproperly.

Please keep instruction manual to properly maintain your model.

1.An RC Model is not a toy! Improper operation or misuse may lead to serious damage or loss. It is

prohibited for children under 14 years to operate this product.

2.Keep it away from high temperature environment and corrosive chemicals for storage and flight.

(the operation temperature: from:-10℃to 50℃)

3.If you are not an experienced pilot or have not flown this type of model before, we recommend that

you get assistance of an experienced pilot for your first flights. Please avoid flying with other RC

models with same frequency.

4.Please choose a open flight area and use the training gear set for your first fight in order to minimize

your loss due to control mistakes.

1.To avoid the loss of the property of others, please keep away from high tension power lines, high

buildings or any other obstacles while flying!

2.Keep away from crowds in case of accidents!

3.Do NOT operate in rain, thunder, storms, lighting, strong wind or any other bad weathers to ensure

your and the helicopter’s safety!

4.Please avoid using in a bathroom or a rainy day to prevent moisture or water vapor from entering the

helicopter inside which may lead mechanical or electronic components malfunction and cause unex-

pected accidents!

5.Do Not re-equip, upgrade or repair your helicopter with the accessories outside the DTS parts catalog

in order to ensure the safety of the model structure!

6.Keep people and objects away from the spinning unit and parts in case of damage or injury!

1.Please make sure the helicopter frequency will not interfered with others before every flight.

2.You should confirm the batteries of your transmitter and helicopter are fully charged before every

flight and your first flight.

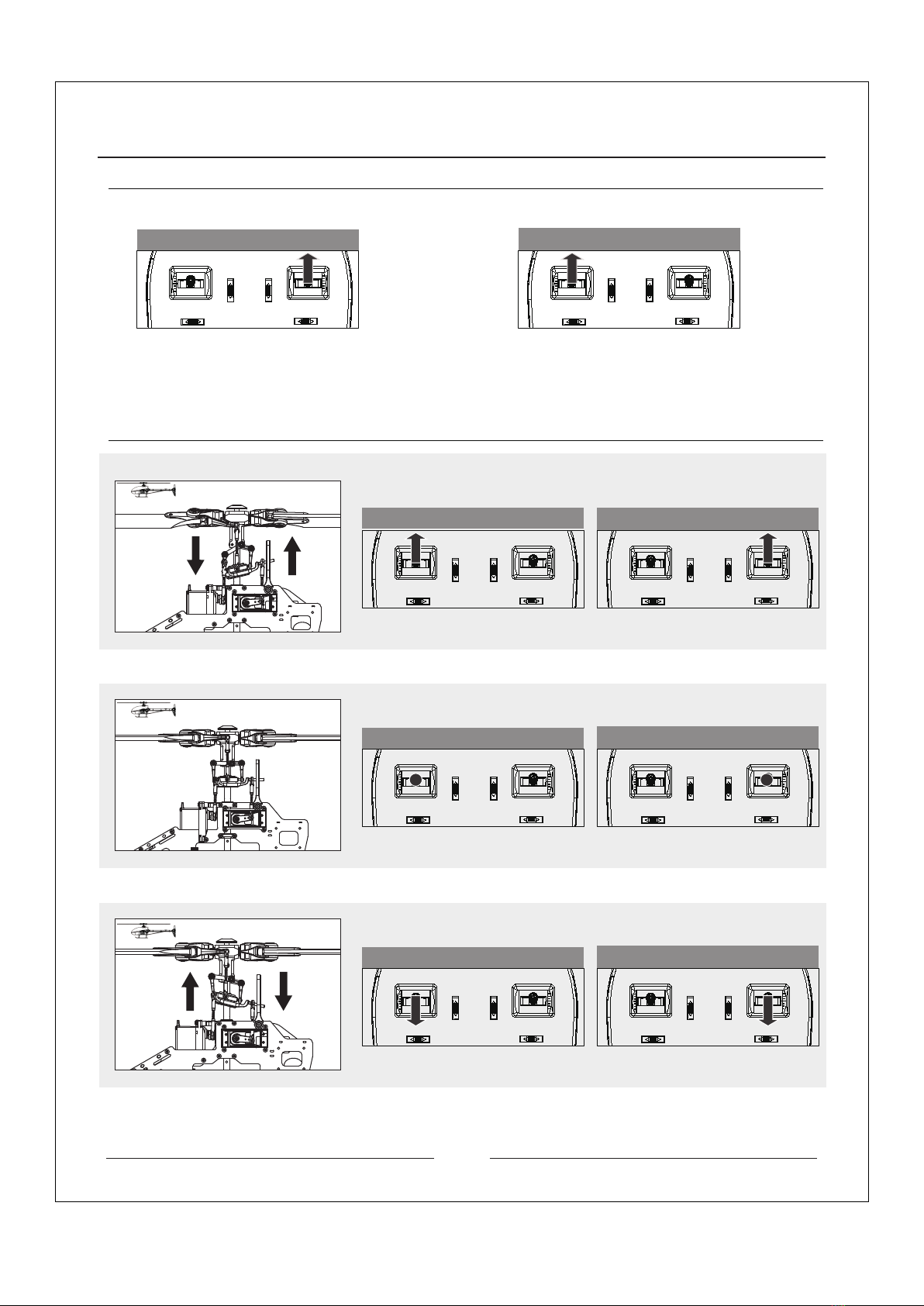

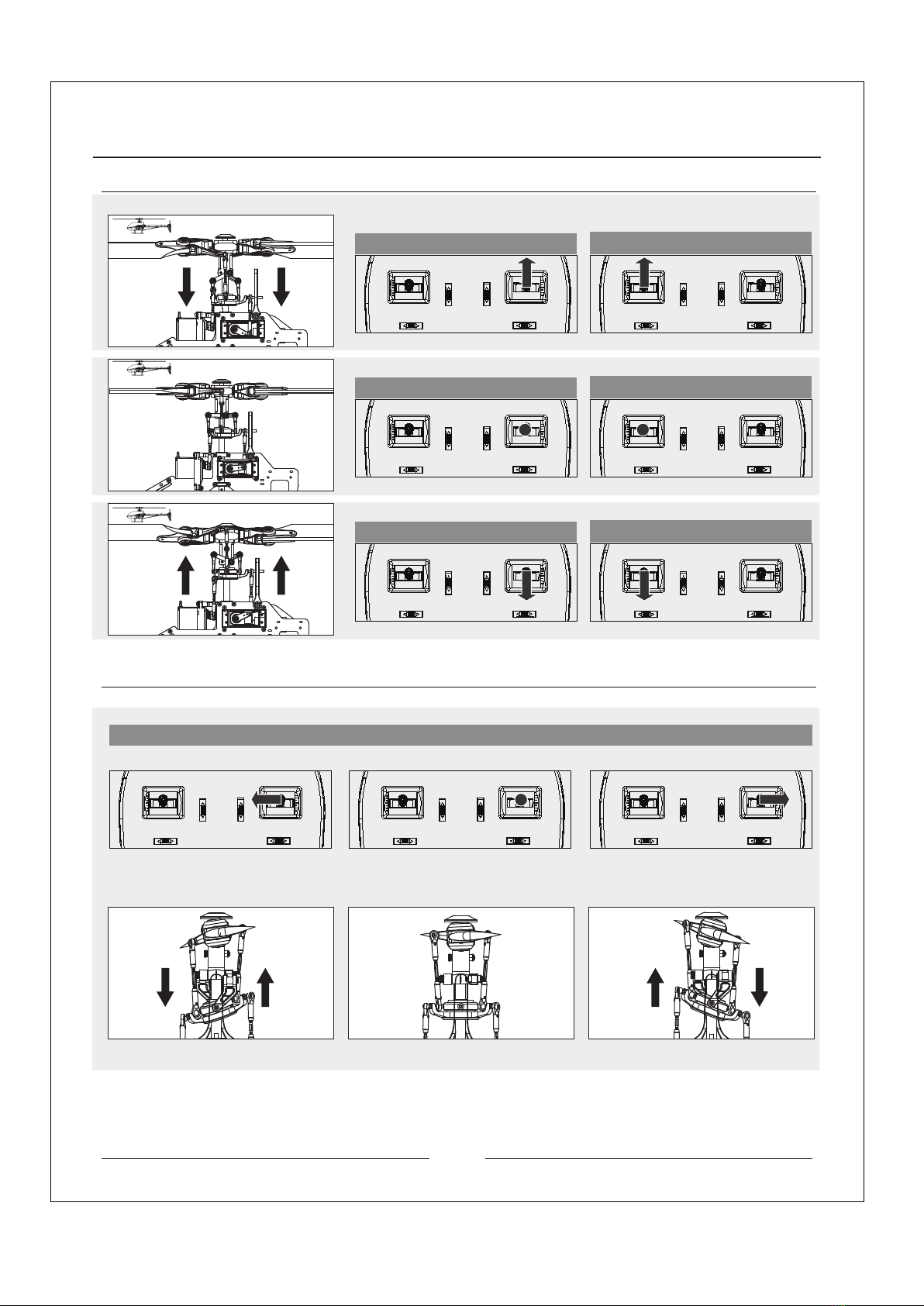

3.Both the throttle stick (left-hand stick) and throttle trim MUST be in their lowest position before every

flight. Each time before your flight, you must ALWAYS turn on the transmitter power first before con-

necting the flight battery to the receiver. After your flight, you should disconnect the flight battery from

the receiver before turn off the transmitter.

4.Please make sure that every servos function properly with correct directions after powering on.

5.Make sure every connection of pushrods is proper and the helicopter battery placed in fixed position.