Dual 622 User manual

Other Dual Speakers manuals

Dual

Dual DMP66 Operating instructions

Dual

Dual DMP670 Operating instructions

Dual

Dual LU48BTS User manual

Dual

Dual SBX6502 User manual

Dual

Dual L83BK Operating instructions

Dual

Dual DMP670 User manual

Dual

Dual LU Series Operating instructions

Dual

Dual CS 505-1 User manual

Dual

Dual DC265 Operating instructions

Dual

Dual DMS652 Operating instructions

Dual

Dual CST 100 User manual

Dual

Dual DMP672 User manual

Dual

Dual LS205EB Operating instructions

Dual

Dual LU47PB Operating instructions

Dual

Dual DMP670 User manual

Dual

Dual DC265W Operating instructions

Dual

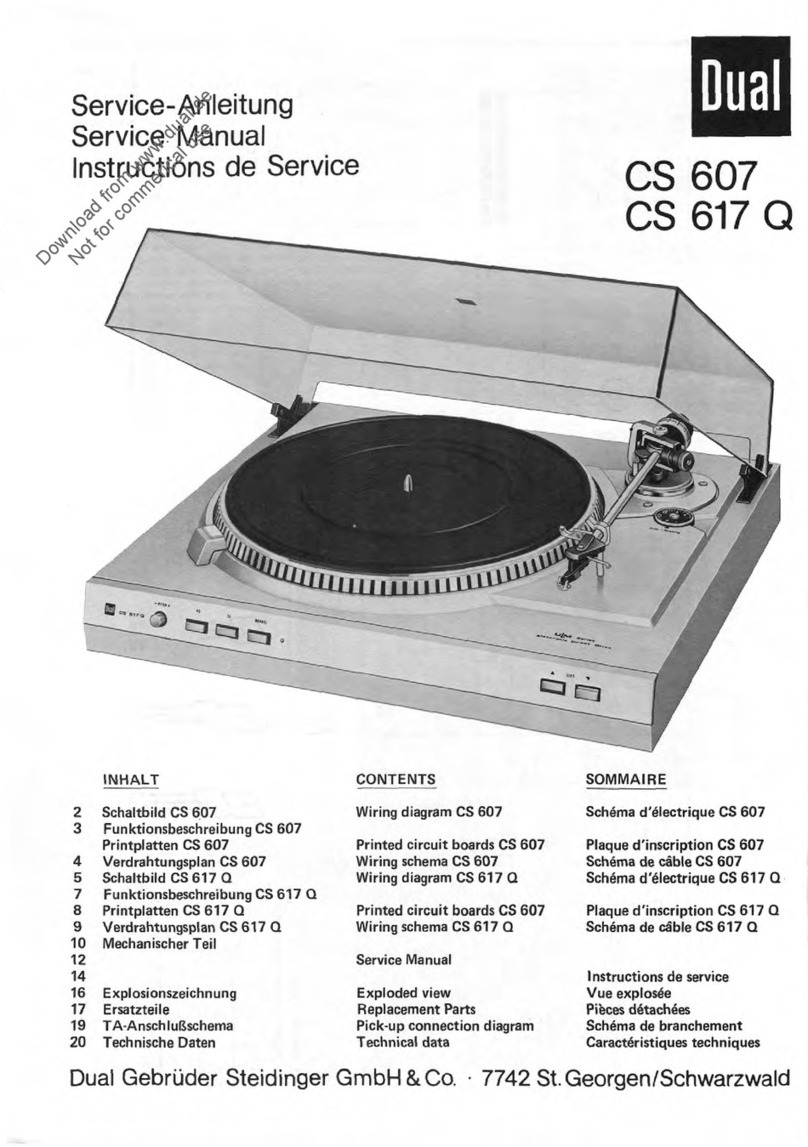

Dual CS 607 User manual

Dual

Dual LU43PB Operating instructions

Dual

Dual ASP 128 User manual

Dual

Dual DMS651 Operating instructions