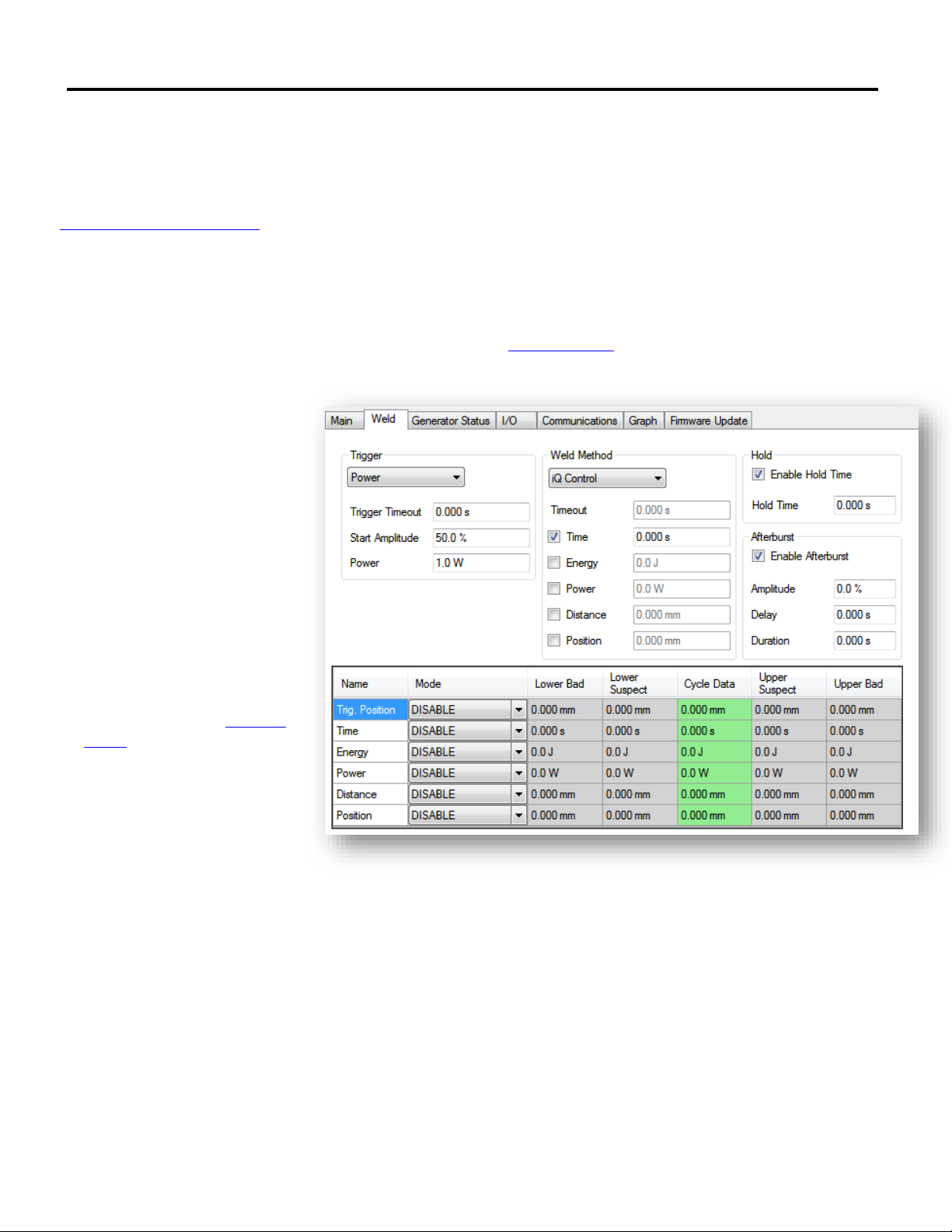

Programming the Aim Generator for use with hard wired connections using iQ Commander

IQ Commander is a PC based utility that can be used to communicate to Dukane generators that contain a USB port. This utility can

be downloaded from the following location:

https://update.dukane.com/

The following control parameters are available via iQ Commander:

1. Set weld method and associated values.

2. Set Amplitude, Ramp Up Time, and Ramp Down Time.

3. Enable iQ Control and program Weld Methods.

4. Enable and set Trigger by Power or Trig. Distance parameters. (See App Note AN506 for Trigger by Power settings)

5. Enable and set Hold and Afterburst.

6. Enable checking for Good, Suspect and Bad Parts.

7. Configure advanced I/O settings.

Parameters that can be obtained

via iQ Commander

1. All parameters that are configured

via iQ Commander.

2. Real time data which includes

welder state, frequency, power,

position, and amplitude.

3. Weld cycle data from previous weld.

Operations that can be done via

iQ Commander

1. Scan an ultrasonic stack to

determine the optimal Free Run

Frequency value. (See App Note

AN512)

2. Test the ultrasonic Stack for

operating frequency and power.

3. Weld a part.

4. Select a probe when an MPC

module is connected.

NOTE: If Weld Time is not used as a control parameter, a weld Timeout needs to be programmed.

Generator Cloning:

If a generator needs to be swapped and a new generator put in its place, it is possible to clone the generator setups and complete

configuration so that it can be loaded into the new generator. This is done through iQ Commander by going to the File menu and

selecting Clone Generator to File. This will save the complete generator configuration and setups for later use. Cloning can only be

performed on generators where the model number precisely matches both generators. If the model number does not match exactly,

cloning will be prohibited.

Saving Setups:

Setups can be saved by opening the FILE menu and clicking on Save A