IMPORTANT INFORMATION – please read before you start

• Carefully read the complete user guide before use and

always follow instructions including those on the paint

pack packaging.

• Keep user guide in a safe place for future reference.

• Dispose of all waste packaging properly.

• The PaintPod is for indoor use only.

• Only use PaintPod paint packs, parts, products

and accessories.

• Always wear protective clothing and as with all

decorating, cover furnishings, ooring etc.

• Keep area around your work place clean and tidy to

help avoid accidents.

• Ensure children and animals are kept away at all times

whilst operating the PaintPod.

• Always place and use the PaintPod on a at, stable

and horizontal surface.

• Always unplug the PaintPod after use.

• Keep power lead away from water, heat, oil, sharp

edges and moving parts.

• Keep the PaintPod away from sources of heat, naked

ames or ignition.

• Only use clean warm water to clean the PaintPod.

• Clean the PaintPod thoroughly after each use to

ensure it works effectively next time.

• Only store the PaintPod when clean and dry.

• Dispose of waste water by pouring down the sink.

• DO take care not to trip over the power lead or

delivery tube.

• ONLY USE a CR2032 3v battery in the roller handle.

• WARNING Fire Hazard! DO NOT incinerate waste

batteries.

• DO NOT dispose of batteries as household waste.

Dispose of or recycle according to local authority

guidelines.

• DO NOT store batteries in any location where

temperatures may exceed 40°C.

• DO NOT tamper with the battery.

• When replacing battery, follow manufacturer

instructions.

DO

DO NOT

BATTERIES

MAINS CONNECTION

DISPOSAL

• DO NOT use any other paint with the PaintPod.

Dulux PaintPod paint is specially formulated.

• DO NOT modify the PaintPod.

• DO NOT place PaintPod on ladders or on stair treads.

• DO NOT use hot or boiling water to clean the

PaintPod.

• DO NOT use solvents, detergents chemical or abrasive

cleaners to clean the inside or outside of the PaintPod.

•DO NOT pour paint directly into the PaintPod.

• DO NOT use the PaintPod if any parts of it are

damaged, excessively worn, faulty or missing.

• DO NOT put any object or part of your body near any

moving parts of the PaintPod.

• DO NOT use the PaintPod with wet hands.

• DO NOT use the PaintPod in explosive atmospheres.

• DO NOT pour waste water into rain water drains, natural

water courses or on to land.

• DO NOT pull the unit by either the power lead or

delivery tube.

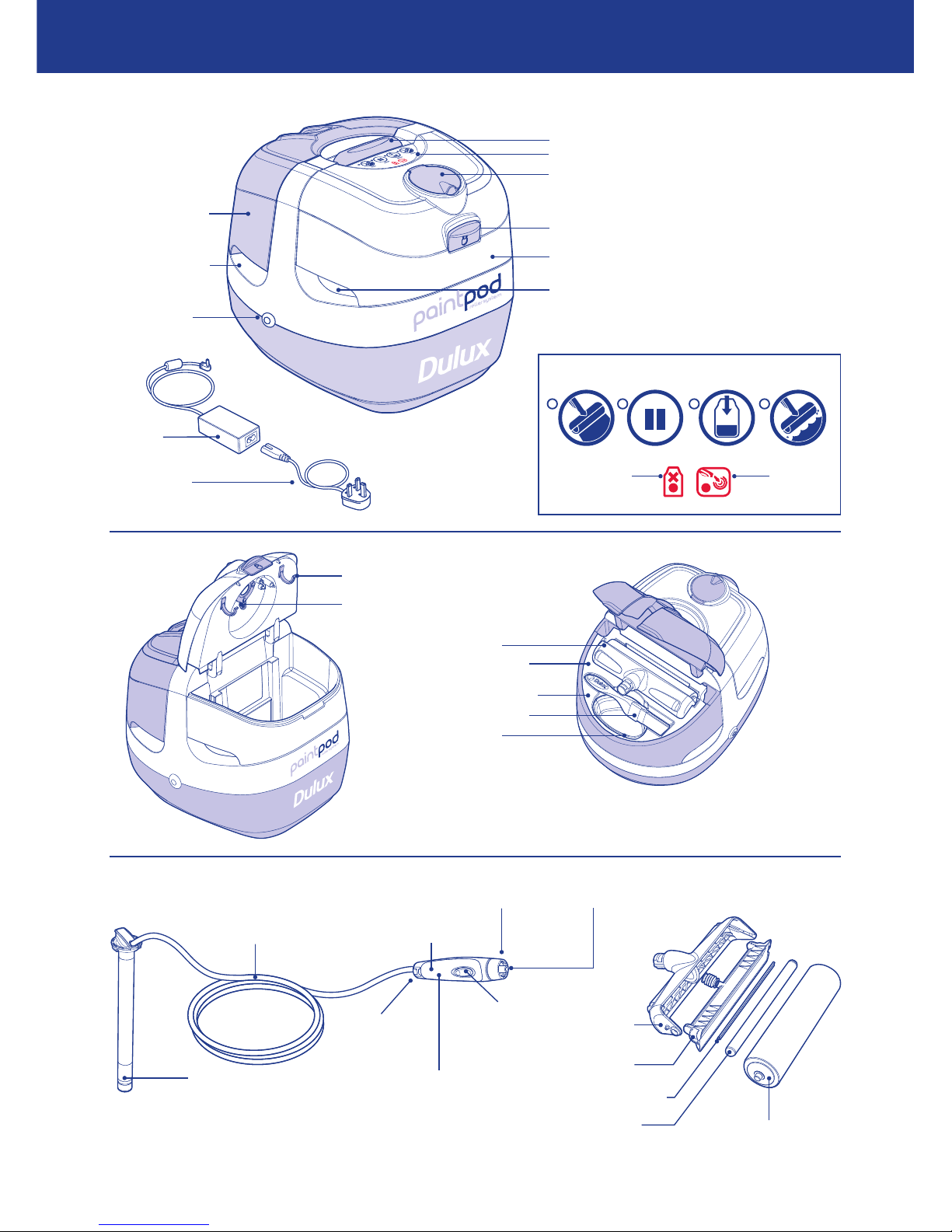

The PaintPod is supplied with a power lead and a tted

3 amp fused plug. It operates at low voltage

and is connected to a separate power supply unit.

IMPORTANT: Please read the following safety

instructions carefully before use.

• DO only use the PaintPod power supply provided.

• If a replacement plug is tted, dispose of the old

plug safely.

• DO NOT use the PaintPod if the power lead

is damaged.

• DO NOT use the PaintPod or power lead without the

plug’s top cover tted.

• ONLY USE 3 amp replacement fuses. Replacement

fuses must conform to BS1362.

• WARNING: IF IN ANY DOUBT PLEASE CONSULT

A QUALIFIED ELECTRICIAN.

Once the product has reached the end of its useful life

or if it has become damaged outside of the one year

guarantee, please dispose of the PaintPod roller system

correctly. Do not dispose of the PaintPod roller system

as household waste. Take to your local authority waste

electrical equipment disposal centre.

1