Idle state: Valves 1 and 2 are closed.

Pressure build-up:The internal mo-

tor pump increases the gas pressure

in the test section by approx. 20 mbar

compared to the input-side pressure

applied to valve V1.

During the test period, the installed

dierential pressure switch monitors

the test section for leakage. If the test

pressure is attained, the motor pump

is switched o (end of test period). The

release time (10-34 s) depends on the

test volume (max. 8.0 l) and input pres-

sure (max. 500 mbar). If the test section

is tight, the contact is released to the

automatic burner control after max. 34

s - the yellow signal lamp lights up.

If the test section is leaky or if the pres-

sureincreaseby+20mbarisnot attained

during the test period (max. 34 s), the

VPS 508 switches to fault.The red signal

lamplightsas long as thecontactrelease

by the regulator or thermostat is present

(heat requirement).

If there is a short power failure during

the test or burner operation, the test

is started again automatically.

If the pumping time < approx. 10s,

the pressure dierence between the

testingsystemandtheinletpressureis

balanced after pumping is nished.

Operation: The internal valve of the

VPS 508 is closed.

Program sequence

Functional description

The VPS 508 operates depending on

pressure build-up.

Theprogrammodulestartstofunction

when heat is requested.

Test is performed depending on the

burner functional procedure:

Check prior to burner start or

Check during pre-purge period or

Check after burner shut-down

Function principle

Release period tF

Period which a VPS requires to per-

form a complete operation procedure.

The release period of the VPS 508

depends on test volume and input

pressure:

tF max. ≈ 34 s

Test period ttest

Pumping time of motor pump.

Test volume VTest

Volume between V1 output-side and

V2 input-side and the intermediate

tube pieces.

Vtest min. / VPS 508 = 1,5 l

Vtest max. / VPS 508 = 8 l

V1

p = 500 mbar

max.

V2

VPS 508

p

2

p

a

p

1

p

e

p

2

p

a

p

1

p

e

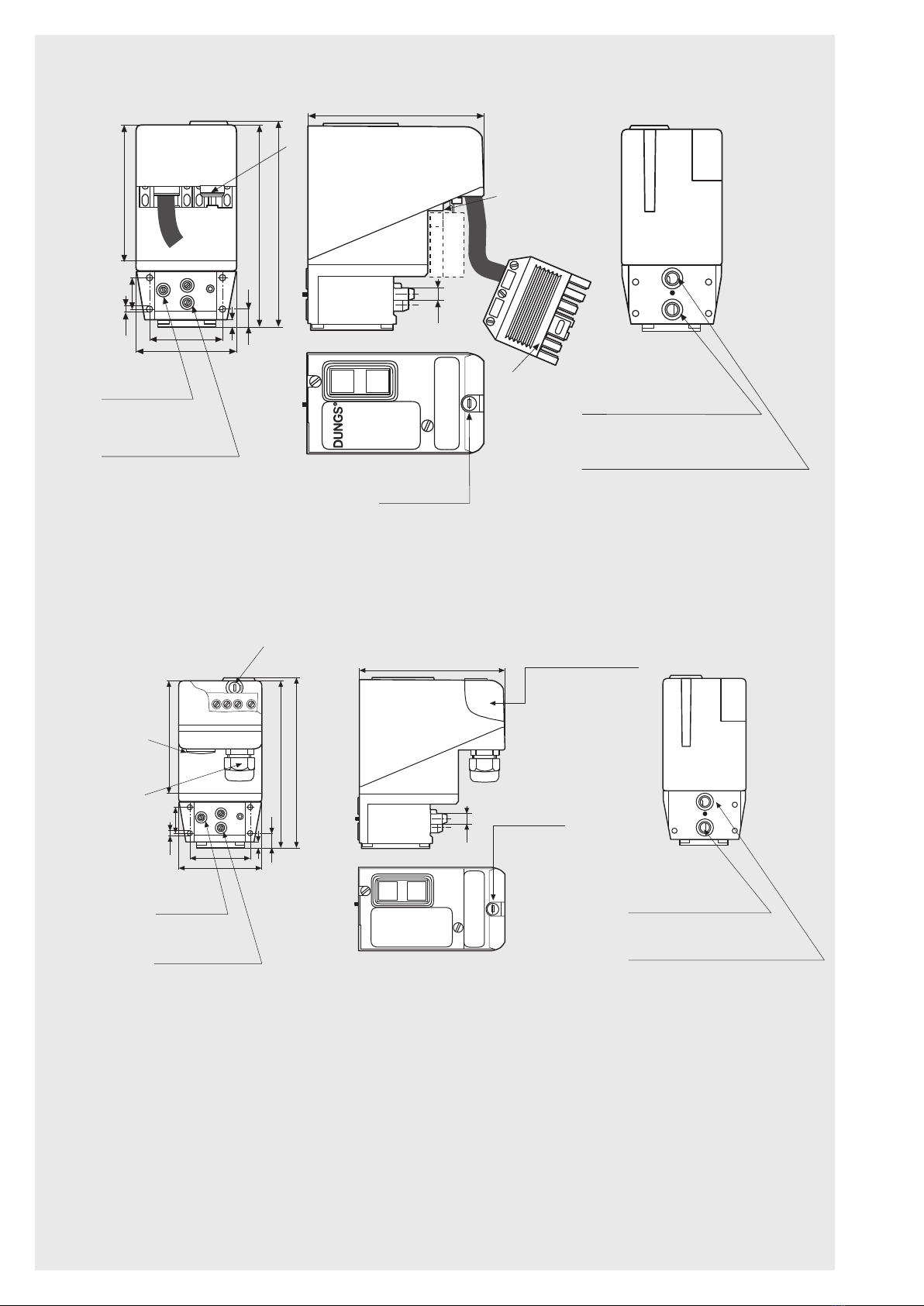

DMV-D(LE)

A

A Program module

Instrument gland

Connection

p + 20 mbar

e

V1

p = 500 mbar

max.

V2

VPS 508

p2

pa

p1

pe

p2

pa

p1

pe

Program

modul

p

e

V1

p = 500 mbar

max.

V2

VPS 508

p2

pa

p1

pe

p2

pa

p1

pe

Program

modul

p

e

V1

p = 500 mbar

max.

V2

VPS 508

p2

pa

p1

pe

p2

pa

p1

pe

Program

modul

p

e

p

e

p

e

p + 20 mbar

e

V1

p = 500 mbar

max.

V2

VPS 508

p

2

p

a

p

1

p

e

p

2

p

a

p

1

p

e

Program

modul

p

e

V1

p = 500 mbar

max.

V2

VPS 508

p

2

p

a

p

1

p

e

p

2

p

a

p

1

p

e

Program

modul

p

e

V1

p = 500 mbar

max.

V2

VPS 508

p

2

p

a

p

1

p

e

p

2

p

a

p

1

p

e

Program

modul

p

e

p

e

p

e

p + 20 mbar

e

V1

p = 500 mbar

max.

V2

VPS 508

p

2

p

a

p

1

p

e

p

2

p

a

p

1

p

e

Program

modul

p

e

V1

p = 500 mbar

max.

V2

VPS 508

p

2

p

a

p

1

p

e

p

2

p

a

p

1

p

e

Program

modul

p

e

V1

p = 500 mbar

max.

V2

VPS 508

p

2

p

a

p

1

p

e

p

2

p

a

p

1

p

e

Program

modul

p

ep

ep

e

Operation

Idle state Pressure

build-up

Field of application

Test volume

Vprüf [l]

Release period

23456 7 81

4

2

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

p

1

/p

e

= 100 mbar

p

1

/p

e

=

20 mbar

p

1

/p

e

= 200 mbar

p

1

/p

e

= 300 mbar

p

1

/p

e

= 500 mbar

tF [s]