8of 38

Operation

Self-Test

The Terranova® 752A will perform a self-test at power ON. Each step is initiated by a BEEP

sound in the following sequence:

1. All display segments become illuminated for CHANNEL 1

2. All LED indicators (except HV ON/OFF and HIGH VOLT INTERLOCK IS OPEN)

become illuminated for CHANNEL 1

3. Steps 1 and 2 repeat for CHANNEL 2

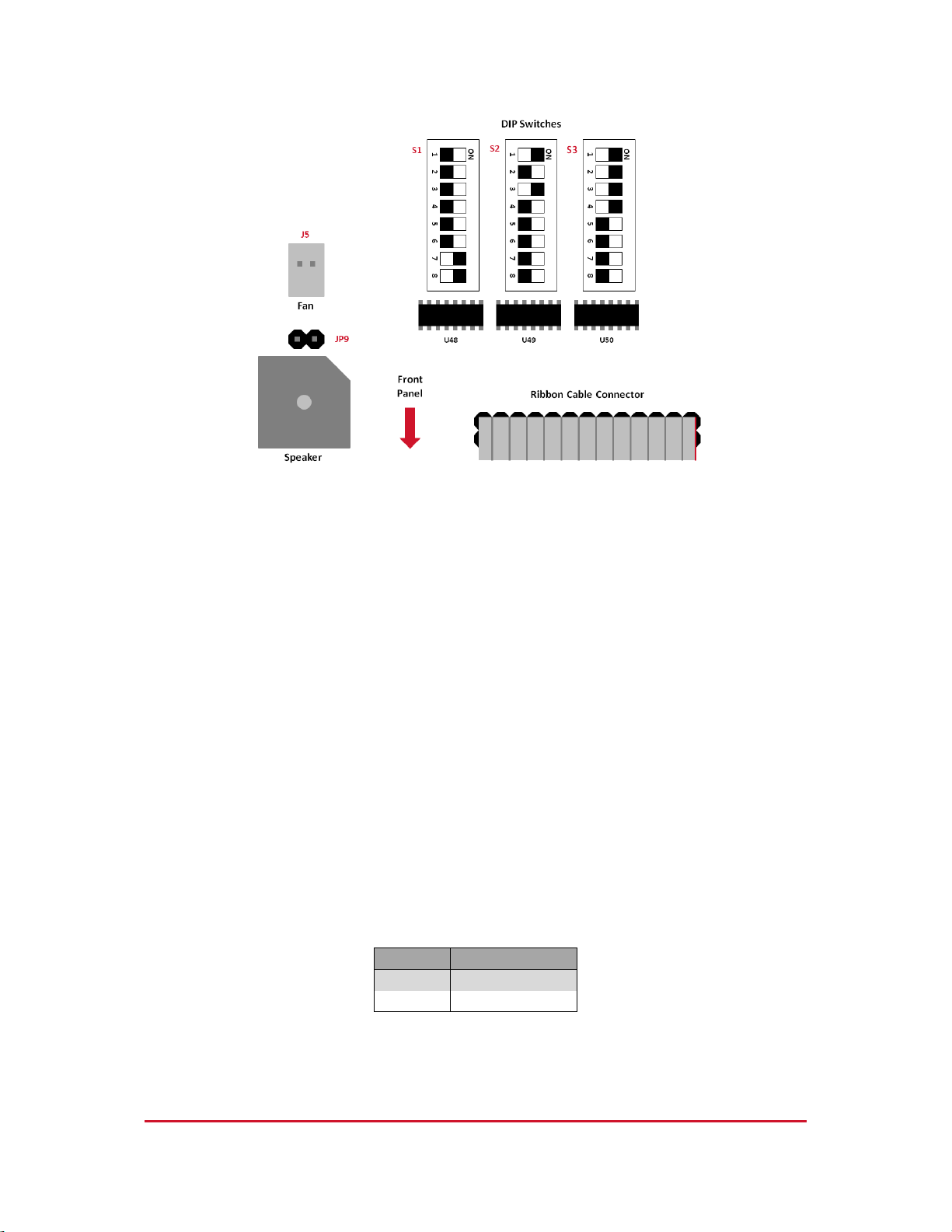

4. CHANNEL 1 CURRENT display reads DIP switch code (e.g. 0FC0)

See Internal DIP Switch Setup

CHANNEL 1 PRESSURE display reads the firmware version (e.g. 1.82);

CHANNEL 2 CURRENT display reads RS-485 address (e.g. 5)

See Changing the RS-485 Address

CHANNEL 2 PRESSURE display reads the model number (e.g. 752A)

The Terranova® 752A will enter Standby Mode if Self-Test is successful. In Standby Mode, the

HIGH VOLTAGE display will read OFF and the LED corresponding to the default or user-selected

pressure unit will become illuminated. The control unit fan will automatically start at power ON.

An RS-485 address will be output regardless of selected communication standard.

Setup Mode

Terranova® 752A unit parameters for CHANNEL 1 or CHANNEL 2 can be set or modified by the

following six-step operation:

1. Press the SELECT button to set or adjust the SET POINT pressure value. Use the

RAISE or LOWER button to increase or decrease the pressure value shown on the

PRESSURE display. Pressure range is from 0.1 x 10-9 to 1.0 x 10-5 in the selected

units of pressure. Default value is OFF. PRESSURE display, respective pressure

unit LED, and SET POINT LED will illuminate during adjustment. See Set Point

Operation

2. Press the SELECT button a second time to adjust the maximum high voltage

supplied by the control unit. Use the RAISE or LOWER button to increase or

decrease the MAX VOLTAGE value shown on the HIGH VOLTAGE display. Voltage

range is from 3.50 kV to 7.00 kV in 0.5 kV steps. Default voltage is 7.50 kV. MAX

VOLTAGE LED will illuminate during adjustment.

3. Press the SELECT button a third time to adjust the maximum current limit of the

control unit. Use the RAISE or LOWER button to increase or decrease the MAX

CURRENT value shown on the CURRENT display. Current range is from 1 mA to

50 mA. Default current is 10 mA. CURRENT display, respective current unit LED,

and MAX CURRENT LED will illuminate during adjustment.