1

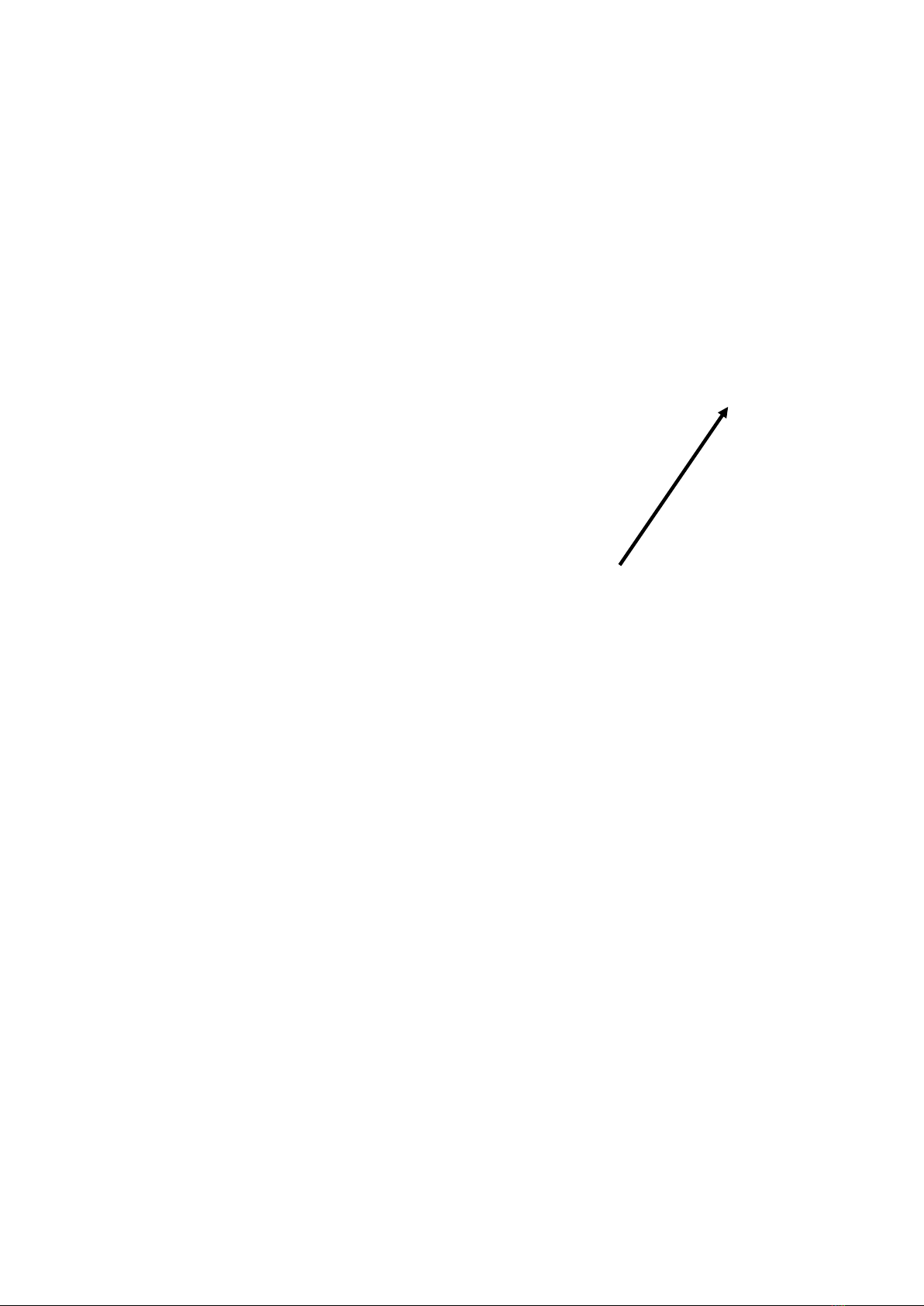

Hook at the lock position

Thanks for you purchase our products. To use this

equipment much better and secure your safety,

you must read this instruction manual and keep it

well. This manual constitutes an integral part of the

products. Please study the warning label and

operation instruction carefully. All of these

information is very important to the safety

operation.

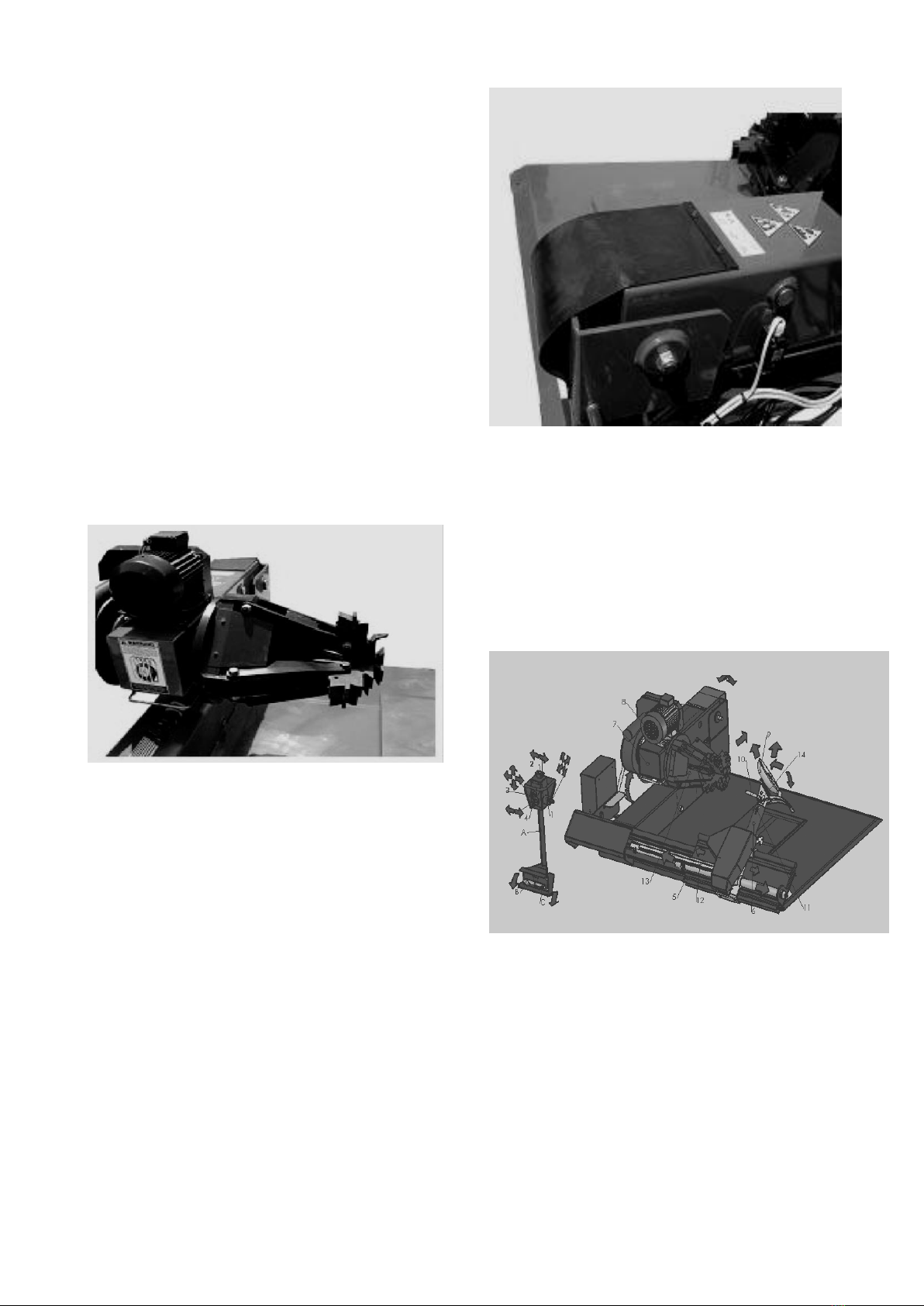

It is the full automatic universal truck tire changer.

The movement of all the work parts is controlled

by a movable console. It can easily

dismount/mount the drop center rim, tubeless

wheel and wheel with ring of truck, agricultural

vehicle and industrial vehicles especially 14"-56"

(Max. wheel diameter is 2300mm and the max.

wheel width is 1100mm)。

This machine can n=only be used to

dismount/mount the tire and not for the other

purpose and we will not be responsible for the

damage of the machine due to the improper use.

Important :The operator should be under the

proper training and with the knowledge of

mechanical, electrical, hydraulic and pneumatic.

Warning!We must dismount/mount after

the wheel is completely deflated!

Warning!It is prohibited to inflate the wheel

when mounted on the machine!

Warning!It needs at least 2person to move the

especially heavy tire!

Warning!The installation and commission of

all the electrical/ pneumatic/ hydraulic parts

must be operated by the professional

technicians.

Warning!You should purchase the wearable

spare parts from the dealers or manufacturer

to guarantee the original parts.

Warning!It is prohibited to move the tool arm

when the hook at the lock position

The manufacturer does not promise to repair

the damage due to the abnormal operation free

of charge.

Technical parameter:

Overall dimension

L .................................................2100~2600 mm

W ..........................................................1900 mm

H ...................................................870~1750 mm

Weight

NW ............................................................987kg

GW:............................................................1252kg

Dual speed gearbox

Speed:..............................1430r/min 2870r/min

Power .......................................................2.4/3kW

Phase ...................................................................3

Power supply ...........................................AC 380V

Noise............................................................≤75 db

Hydraulic motor