Content

OverView ..............................................................................................................................................................................3

1.1 Important Note .....................................................................................................................................................4

1.2 Qualified Users ....................................................................................................................................................4

1.3 Notes ....................................................................................................................................................................4

1.4 Danger Warning Signs .........................................................................................................................................6

1.5 Noise Standard .....................................................................................................................................................6

1.6 Training................................................................................................................................................................6

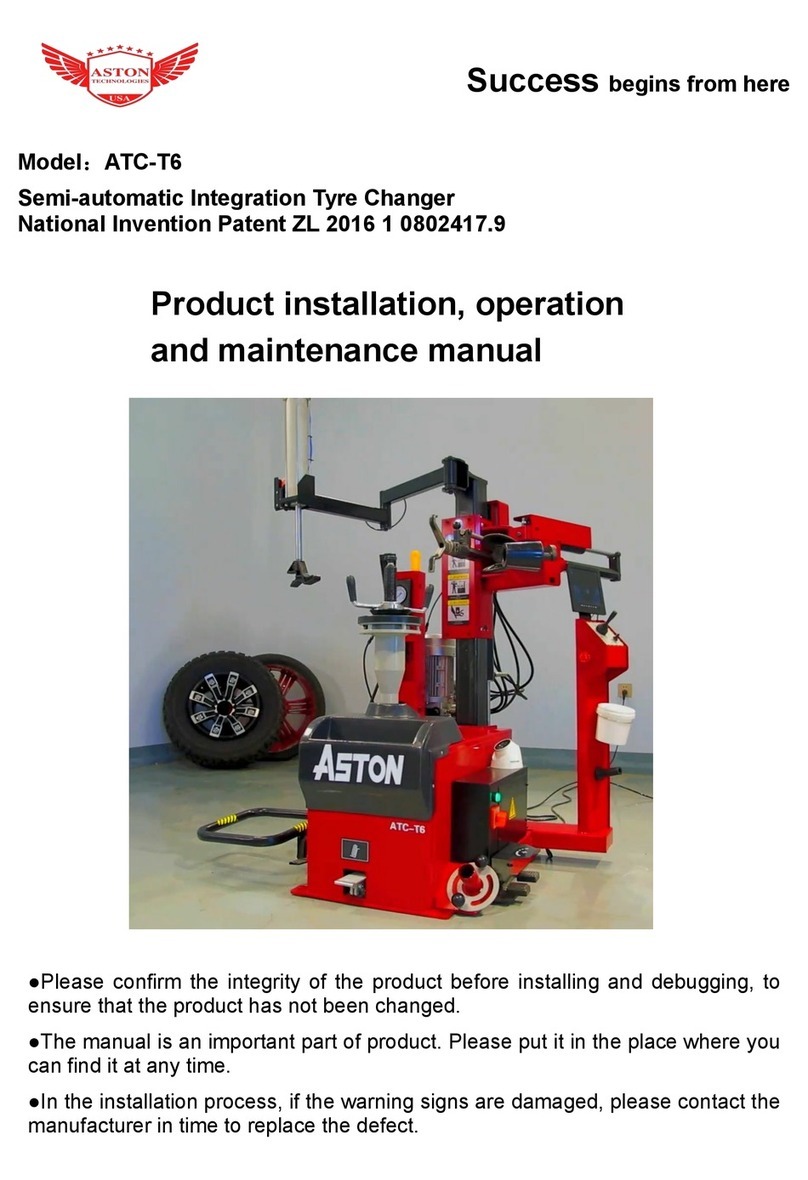

Quipment Introduction..........................................................................................................................................................6

2.1 Product Introduction ............................................................................................................................................7

2.2 Technical Specifications.......................................................................................................................................7

2.3 Transportation ......................................................................................................................................................8

2.4 Figure and part name............................................................................................................................................8

Installation and commissioning instructions.........................................................................................................................8

3.1 Pre Installation Preparation................................................................................................................................10

3.2 Precautions during installation...........................................................................................................................11

3.3 Main installation procedure................................................................................................................................11

3.4 Check the project table after installation............................................................................................................12

3.5 Commissioning and debugging..........................................................................................................................12

Operation declaration..........................................................................................................................................................15

4.1 Operating notes ..................................................................................................................................................15

4.2 Demount and Mount Tires Operation Procedure ...............................................................................................15

Maintenance, storage and scrap ..........................................................................................................................................19

5.1 Maintenance.......................................................................................................................................................21

5.2 Storage and scrap ...............................................................................................................................................22

Fault causes and Solutions ..................................................................................................................................................21