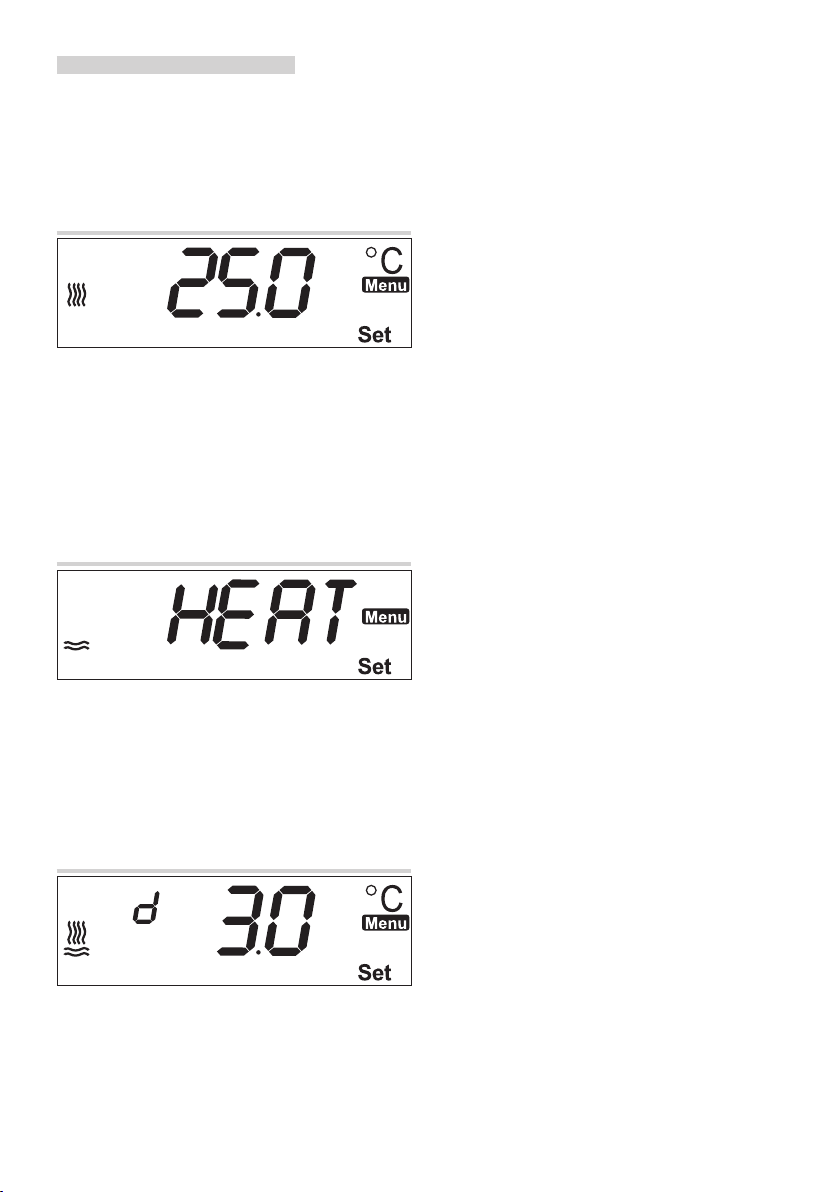

An immersion heater may also be connected to this channel, depending on the power of the heating cable

(e.g. Therm Set vs Thermik Set), and therefore it’s capacity to provide sufficient warmth in the cooler months.

3.4 Temperature Alarm: When the water temperature falls below, or exceeds the programmed temperature

set-point, an audible and visual temperature alarm is activated. The alarm window can be preset between +/-

1° and 5° C. +/-3° C is set as the factory default. The alarm function can be switched on or off.

By default the function is set to “off”, to prevent the alarm operating on initial use when the sensor is not yet

positioned in the aquarium and the room temperature is too high or too low.

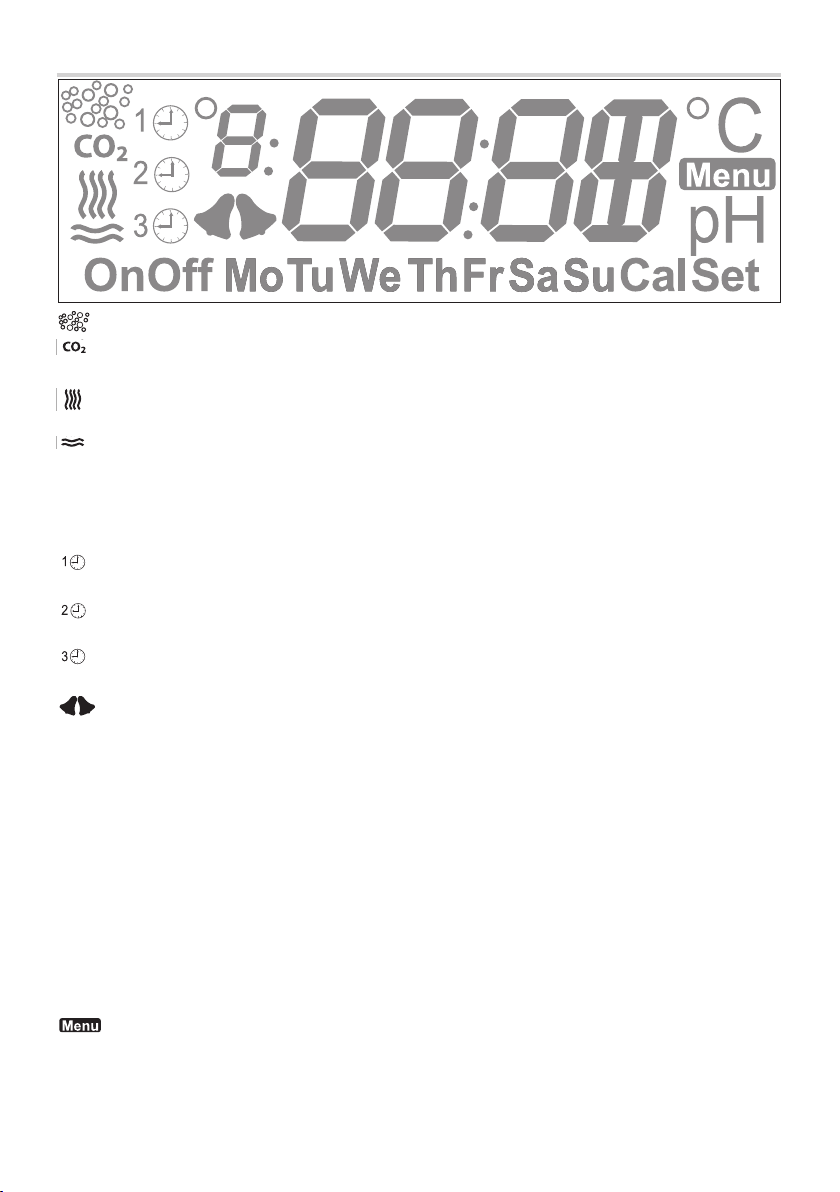

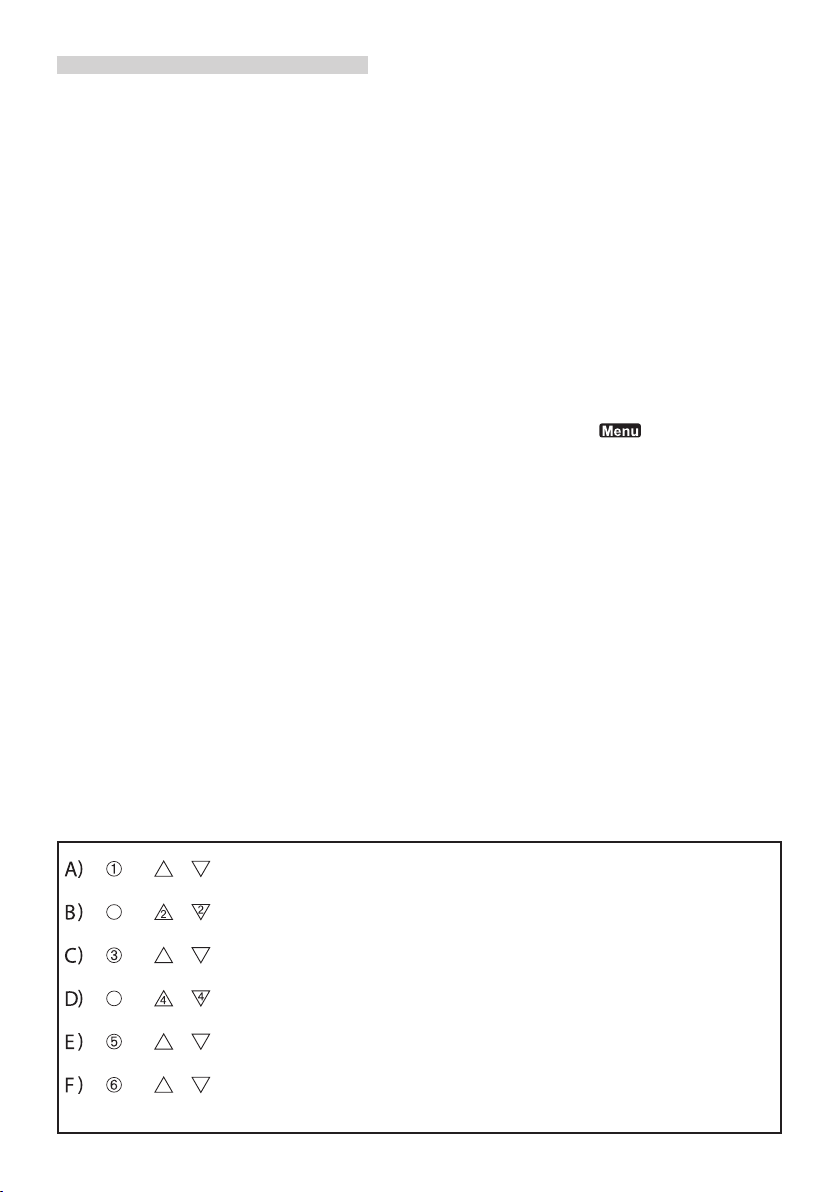

3.5 Circuit Times: Via 3 time-controlled channels, for example, day and night lighting, circulation pumps or

filters can be switched on and off, up to 8 times each, per day. External devices can be programmed daily,

Mo-Su, Mo-Fr, Sa-Su. The weekdays are abbreviated on the display. The capacity of the entire Power Unit is

1,500 W total. With individual channels having a maximum capacity of 1,000 W each.

3.6 pH Set Point: The pH set point can be adjusted within the limits of 4.0 - 9.9. Outside of these limits, the

pH channel is switched off. With the connection of a Dupla pH electrode, the pH level, may be continuously

monitored, and with a Dupla Magnetic Valve also connected to the Multicontrol, pH-controlled CO

2

fertilisation

may be utilised. Switch hystereris (the difference between the switching point and the triggering point) is 0.1

pH, and the control accuracy is +/- 0.1 (reference value). In order to ensure the accuracy of measurement and

therefore the control circuit, the MultiControl provides an optional six-week calibration memory function

CAUTION: If no pH electrode is connected to the MultiControl, so that the BNC socket is open, inevitably, ficti-

tious pH values will be displayed in individual as well as toggle mode (where the displayed values change from

one to the next in a 2 second cycle). To overcome this, by default, these values are hidden when a pH electrode

is not connected. If you want them to be displayed, please select “on” when programming the

pH point setting.

3.7 pH Alarm: When the programmed pH set-point is either not met or exceeded, there is an acustical and

optical pH alarm. The alarm window can be set between 0.5 and 4.0 pH deviation from the set point. By de-

fault, a deviation of pH 0.5 is preset. The alarm function can be enabled or disabled (switched “on” or “off”).

The beep can be silenced by pressing the ▲or ▼key.

3.8 Calibrate pH Electrode: The factory setting of the calibration points is pH 7 and pH 4, the calibration

sequence first is pH 7, then pH 4. The calibration process can be cancelled by pressing the ▲ and ▼ key

simultaneously.

3.9 Calibration Memory Function: With this feature enabled, every six-weeks “CAL” and “pH” flashes on

the display as a reminder to check the pH electrode calibration. In order to calibrate the pH electrode, enter

programming mode by pressing the “Menu” key and go to the menu item “CAL” and “pH”.

To disable of the calibration memory function, continue to scroll through the menu items and set the function

to “off”. If you prefer not to carry out a calibration at the moment, the memory display clears after activating

any key and reappears in another 6 weeks.

3.10 Time: The MultiControl has a built-in real-time clock. Changing from summer time to winter time must

be done manually.

77