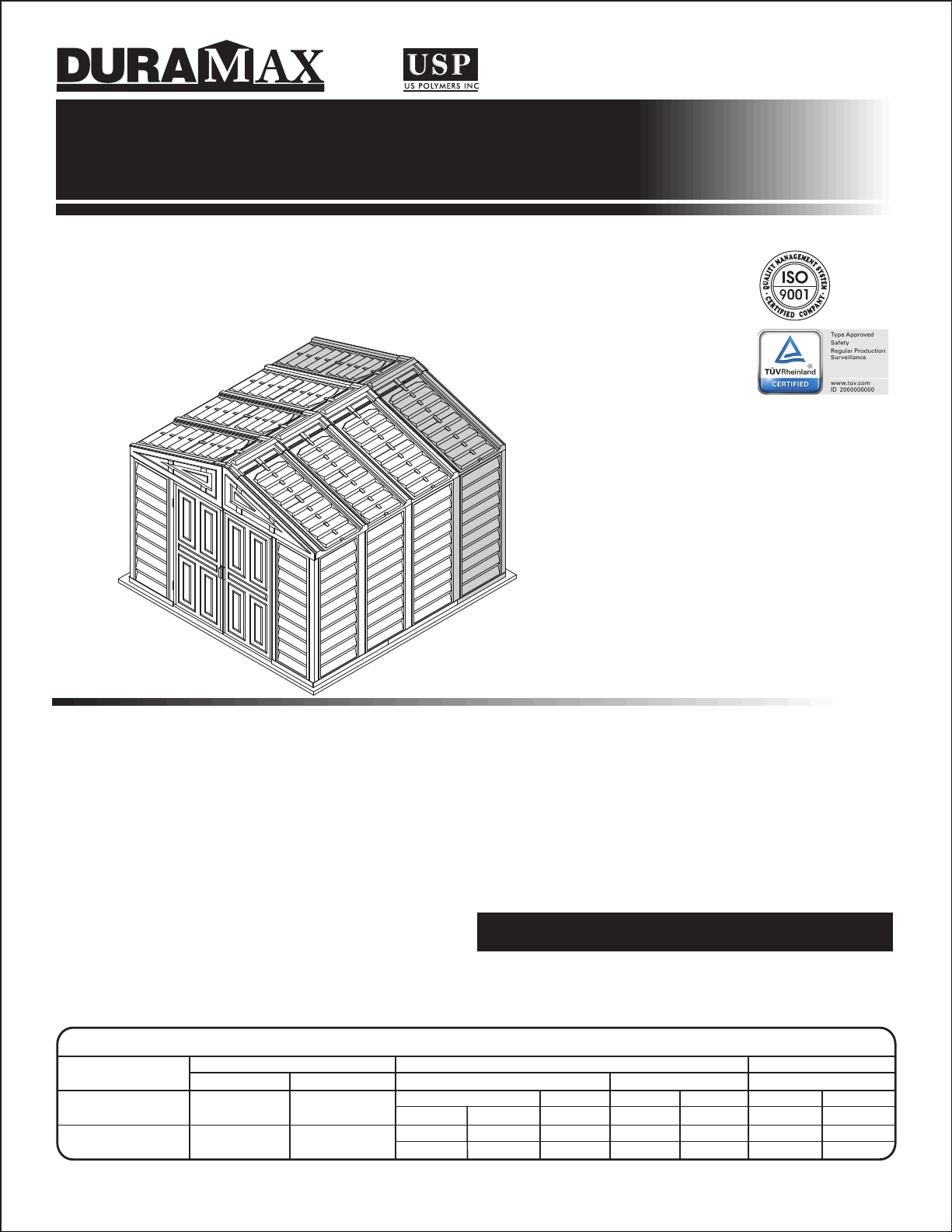

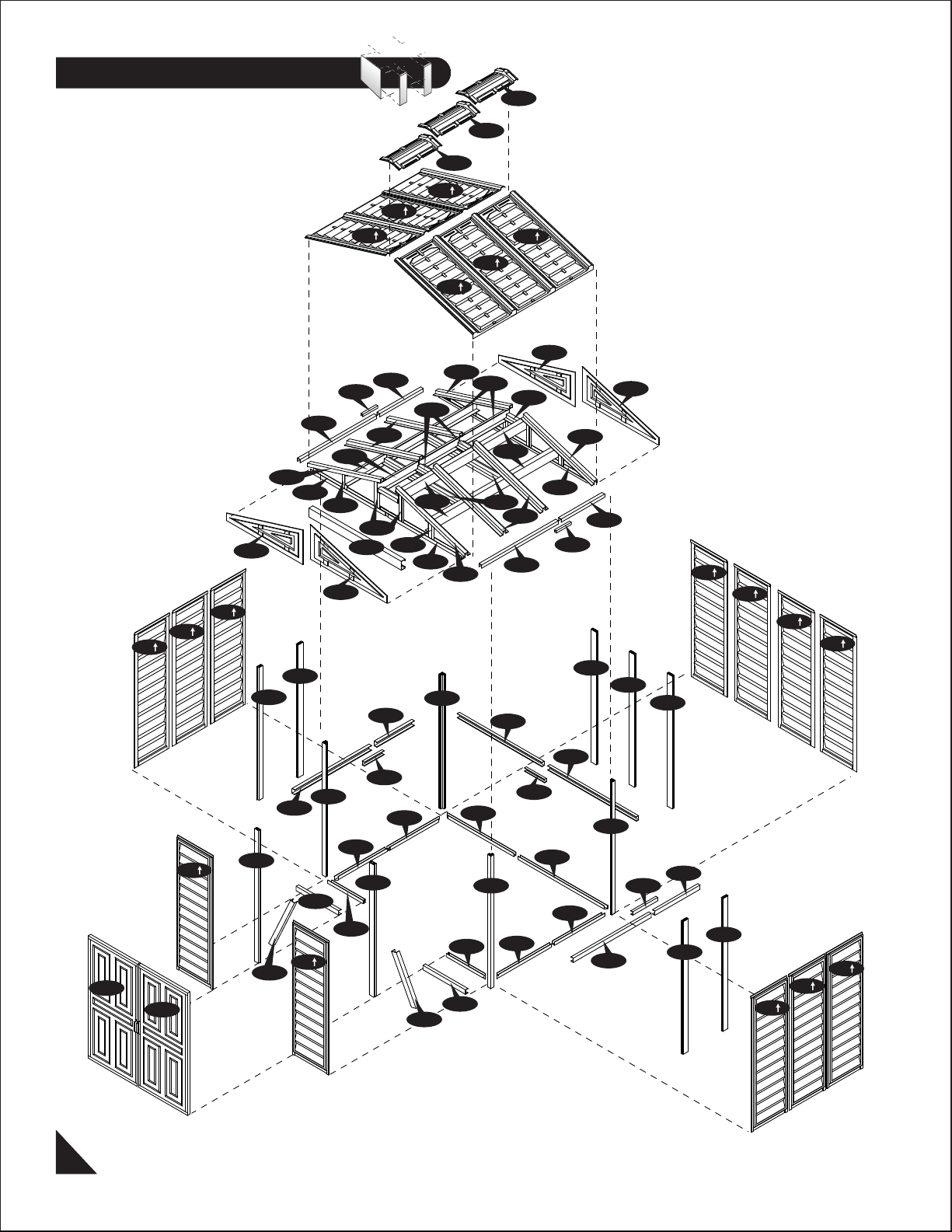

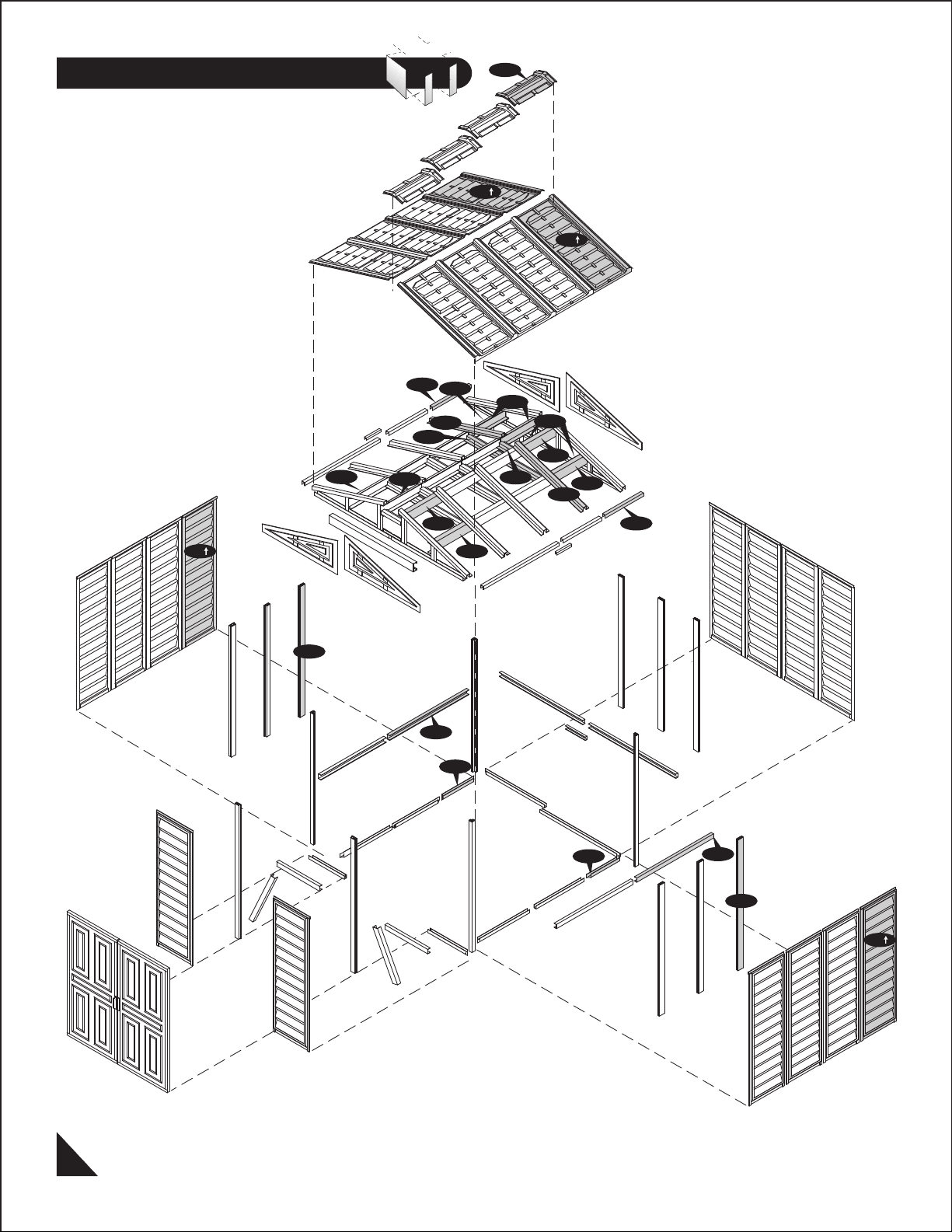

A. Foundation

9

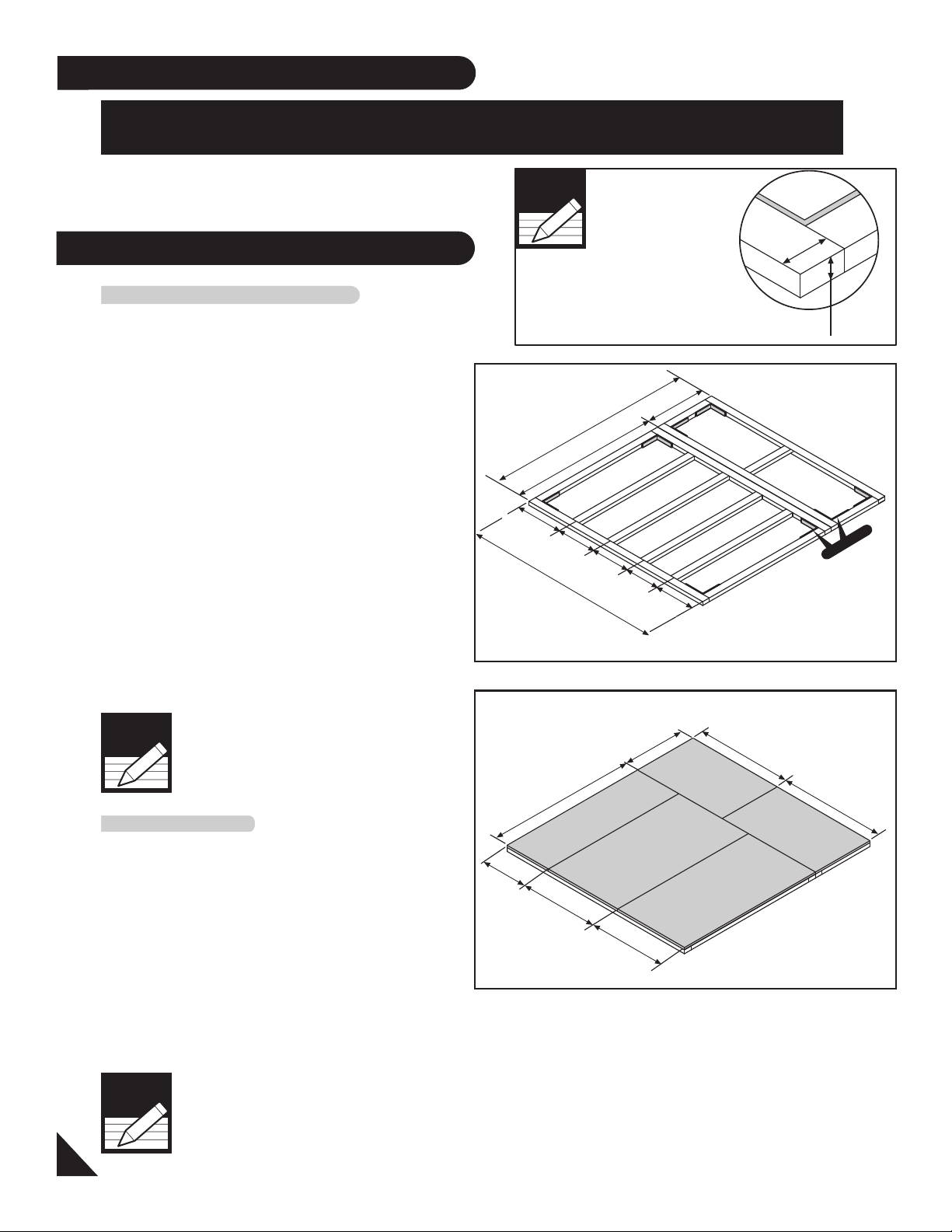

DuraMax must be installed on a level wooden

platform or a level concrete foundation.

2. Using exterior grade CDX 3/4” (19mm) plywood,

cut and fit together the sheets to form solid

foundation as shown. Foundation must be square

and level.

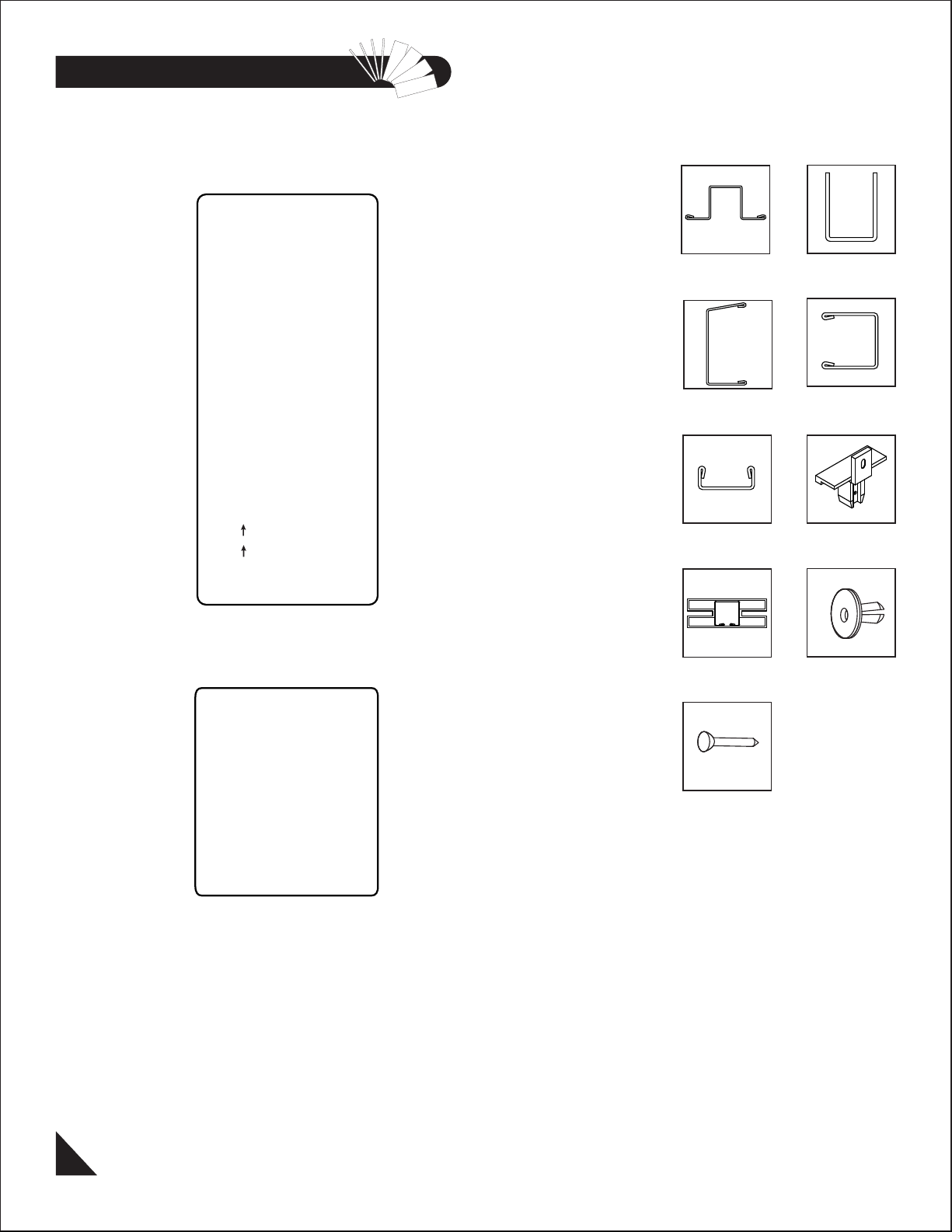

1. Use pressure treated wood studs 2 x 4 (Actual

size 2” x 3 1/2”, 50mm x 88.9mm) to create a

platform frame that has an outside dimension of

126” x 126” (3200mm x 3200mm).

The following are the list of lumber and sizes

you will need.

Wooden Platform (Not Included)

Pressure Treated - Wood Studs:

4ea 2” x 3 1/2” x 126” (50mm x 88.9mm x 3200 mm)

6ea 2” x 3 1/2” x 87 7/8” (50mm x 88.9mm x 2232 mm)

3ea 2” x 3 1/2” x 24 1/8” (50mm x 88.9mm x 613 mm)

Exterior Grade (CDX) - 3/4” (19mm) plywood

2ea 3/4” x 48” x 94 7/8” (19mm x 1219.2mm x 2410

mm)

1ea 3/4” x 30” x 94 1/8” (19mm x 762mm x 2410 mm)

2ea 3/4” x 63” x 31 1/8” (19mm x 1600 mm x 790mm)

L-Brackets: 8ea

The shed must be constructed on a solid

base foundation. A concrete pad or a large size

concrete patio stone squares is recommended for

suitable floor base. Make sure it is firm and level

and will allow drainage away from the site.

The base foundation should be at least 4

inches(100mm)larger than the shed dimensions.

Please refer to the front page of your owner’s

manual for the exterior dimensions of the shed.

Manufacturer is not responsible for the choice

and construction of the foundation

Concrete Platform

Note For a concrete pad base, prepare a level bed for a

firm footing layer of crushed stone. The concrete

pad should then be poured to a thickness of 4

inches (100mm) to 5 inches (125mm). Allow to dry

thoroughly for at least 48 hours

If the shed is assembled with

wooden foundation on soil, use the

soil anchor kit.

Note

Note : If you have DURAMAX Foundation, please follow instruction manual

in that package. If not, follow below wooden platform instruction.

Lay 2 x 4

(Actual size 2”x 3 1/2”, 50mm x 88.9mm)

Note

50

mm (2”)

88.9

mm (3 1/2”)

Part 1:Assembling shed with Extension kit

30”

762 mm.

24”

609.6mm.

94 7/8”

2410mm.

126”

3200mm.

L- BRACKET

31 1/8”

790 mm.

24”

609.6mm. 24”

609.6mm. 24”

609.6mm.

126”

3200mm.

48”

1219.2mm.

94 7/8”

2410 mm. 31 1/8”

790 mm.

30”

762mm.

48”

1219.2mm.

63”

1600.2mm.

63”

1600.2mm.