Note: Check all parts prior to installation.

CODE DESCRIPTION QTY

BLC BASE BAR BACK LEFT 1

BRC BASE BAR BACK RIGHT 1

BSC BASE BAR SIDE LEFT & RIGHT 2

BBFC BASE BAR FRONT LEFT & RIGHT 2

ECC ENTRANCE TAPER CHANNEL 1

DCLC DOOR COLUMN PROFILE LEFT 1

DCRC DOOR COLUMN PROFILE RIGHT 1

ABLC TOP ANGLE BACK LEFT 1

ABRC TOP ANGLE BACK RIGHT 1

ASC TOP ANGLE SIDE LEFT & RIGHT 2

SCC SLIDING CHANNEL COVER 1

SSB SLIDING CHANNEL SUPPORT 1

SLC SLIDING CHANNEL LEFT 1

SRC SLIDING CHANNEL RIGHT 1

RSC ROOF SUPPORT LEFT & RIGHT 2

RF1C ROOF FLASHING (FRONT RIGHT / BACK LEFT) 2

RF2C ROOF FLASHING (FRONT LEFT / BACK RIGHT) 2

RFSA ROOF FLASHING SIDE LEFT & RIGHT 2

RFCC ROOF FLASHING CENTER 1

TSLC DOOR PANEL STRIP TOP LEFT 1

TSRC DOOR PANEL STRIP TOP RIGHT 1

BDSC DOOR PANEL STRIP BOTTOM LEFT/RIGHT 2

DSSC DOOR PANEL STRIP SIDE LEFT & RIGHT 2

DSCC DOOR PANEL STRIP CROSS 4

WCFC WALL PANEL CORNER FRONT LEFT & RIGHT 2

WCBC WALL PANEL CORNER BACK LEFT & RIGHT 2

WSC WALL PANEL SIDE 3

WFLC WALL PANEL FRONT LEFT 1

WFRC WALL PANEL FRONT RIGHT 1

GPLC GABLE PANELFRONT LEFT/BACK RIGHT 2

GPRC GABLE PANEL FRONT RIGHT/BACK LEFT 2

GPS GABLE PANEL SUPPORT 2

RP1C ROOF PANEL FRONT LEFT / BACK RIGHT 2

RP2C ROOF PANEL FRONT RIGHT/BACK LEFT 2

DPLC DOOR PANELLEFT 1

DPRC DOOR PANEL RIGHT 1

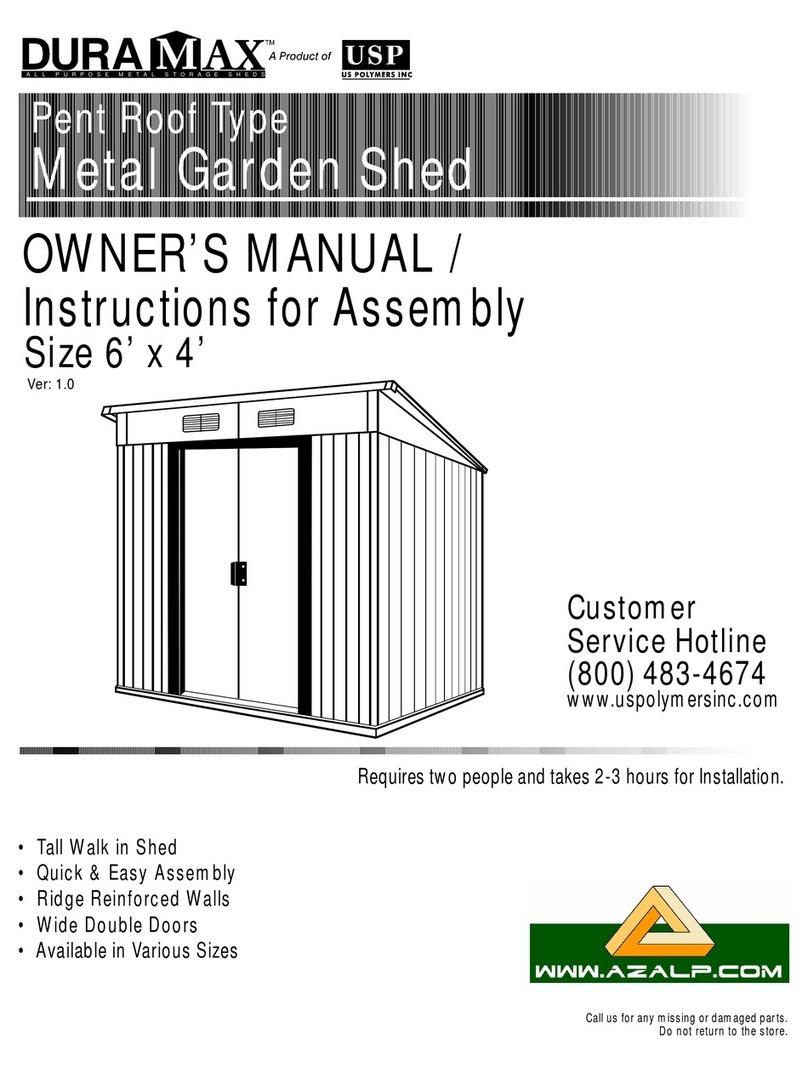

Parts List

Hand Gloves

Cordless Drill - Philips Head

Screw driver - Philips Head

Carpenters Square

Eye Protector

Tools You Will Need

ACCESSORIES

CODE DESCRIPTION QTY

BS BOTTOM SLIDER 4

DH DOOR HANDLE 2

FC FLASHING END CAP 2

TC TOP CORNER 4

TS TOP SLIDER 4

VC VENTILATION COVER 4

PW PLASTIC WASHER 134

PC PLASTIC SCREW COVER 86

WST WEATHER STRIPPING TAPE 2.00 mtr

S1 DIA. 4.2 x 10mm. (5/32” x 3/8”)

SHEET METAL SCREW 156

S2 DIA. 4.2 x 16mm. (5/32” x 5/8”)

SHEET METAL SCREW 22

S3 M4 x 16mm. (5/32” x 5/8”)

MACHINE SCREW W/ NUT 54

8’ Step Ladder

Adjustable pliers

Level - 3ft.

Tape Measure

BOTTOM SLIDER

(BS)

VENTILATION COVER

(VC)

TOP CORNERS

(TC) TOP SLIDER

(TS)

PLASTIC WASHER

(PW) PLASTIC SCREW COVER

(PC)

SHEET METAL SCREW

(S1),(S2) MACHINE SCREW WITH

NUT (S3)

FLASHING END CAP

(FC)

DOOR HANDLE

(DH)

ENTRANCE TAPER

CHANNEL (ECC)

SLIDING CHANNEL COVER

(SCC)

DOOR COLUMN PROFILE

LEFT (DCLC)

DOOR PANEL STRIP SIDE

AND CROSS

(DSSC, DSCC)

SLIDING CHANNEL

(SLC, SRC) SLIDING CHANNEL

SUPPORT (SSB)

ROOF SUPPORT

(RSC)

ROOF FLASHING

(RF1C, RF2C) ROOF FLASHING CENTER

(RFCC)

DOOR PANEL STRIP

TOP AND BOTTOM

(TSLC, TSRC, BDSC)

TOP ANGLE BACK

(ABLC, ABRC)

BASE BAR

(BBFC)

BASE BAR

(BLC, BRC, BSC)

TOP ANGLE SIDE

(ASC)

DOOR COLUMN PROFILE

RIGHT (DCRC)

ACCESSORIES

PROFILES

WEATHER STIPPING TAPE

(WST)

IMPORTANT: USE HAND GLOVES TO PREVENT INJURY.

GABLE PANEL SUPPORT

(GPS)