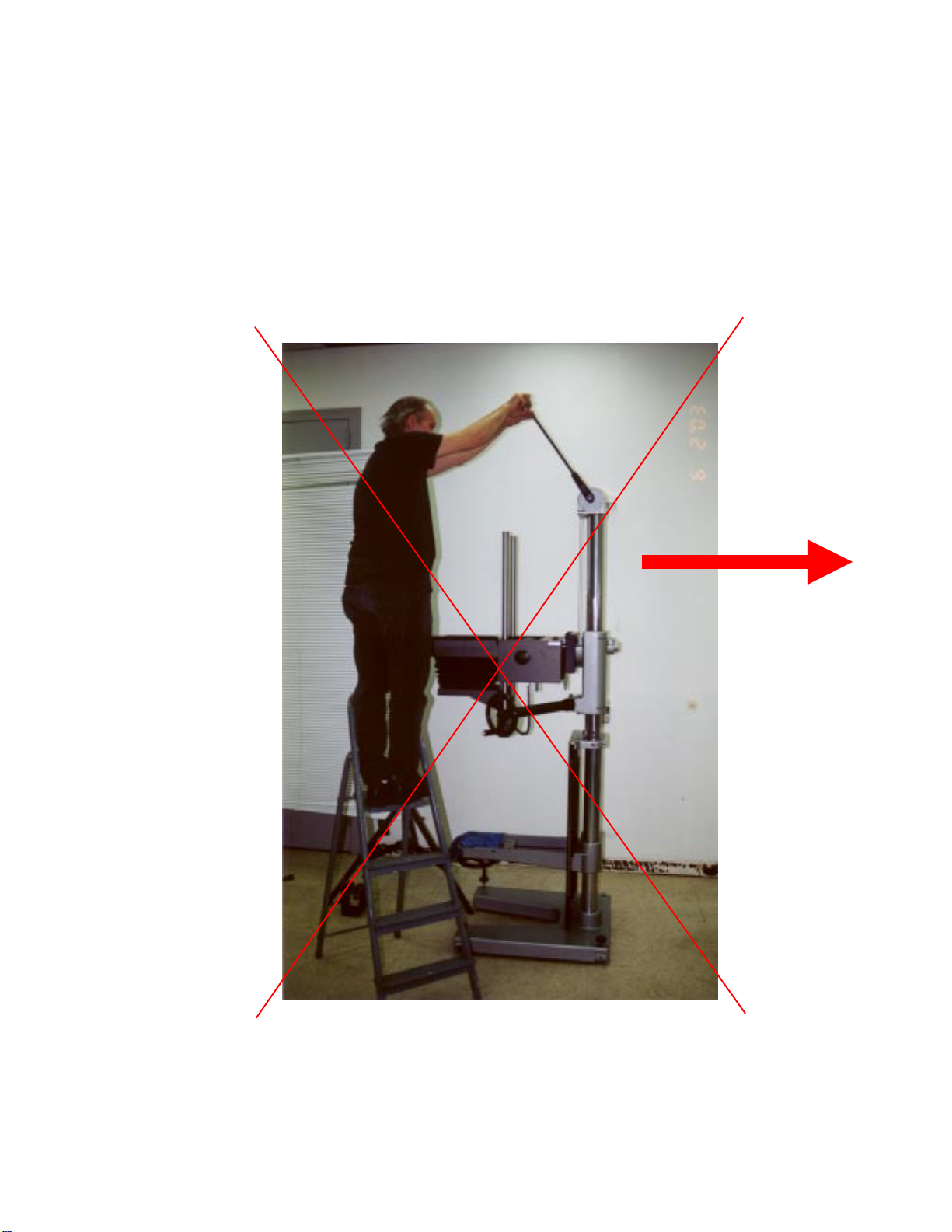

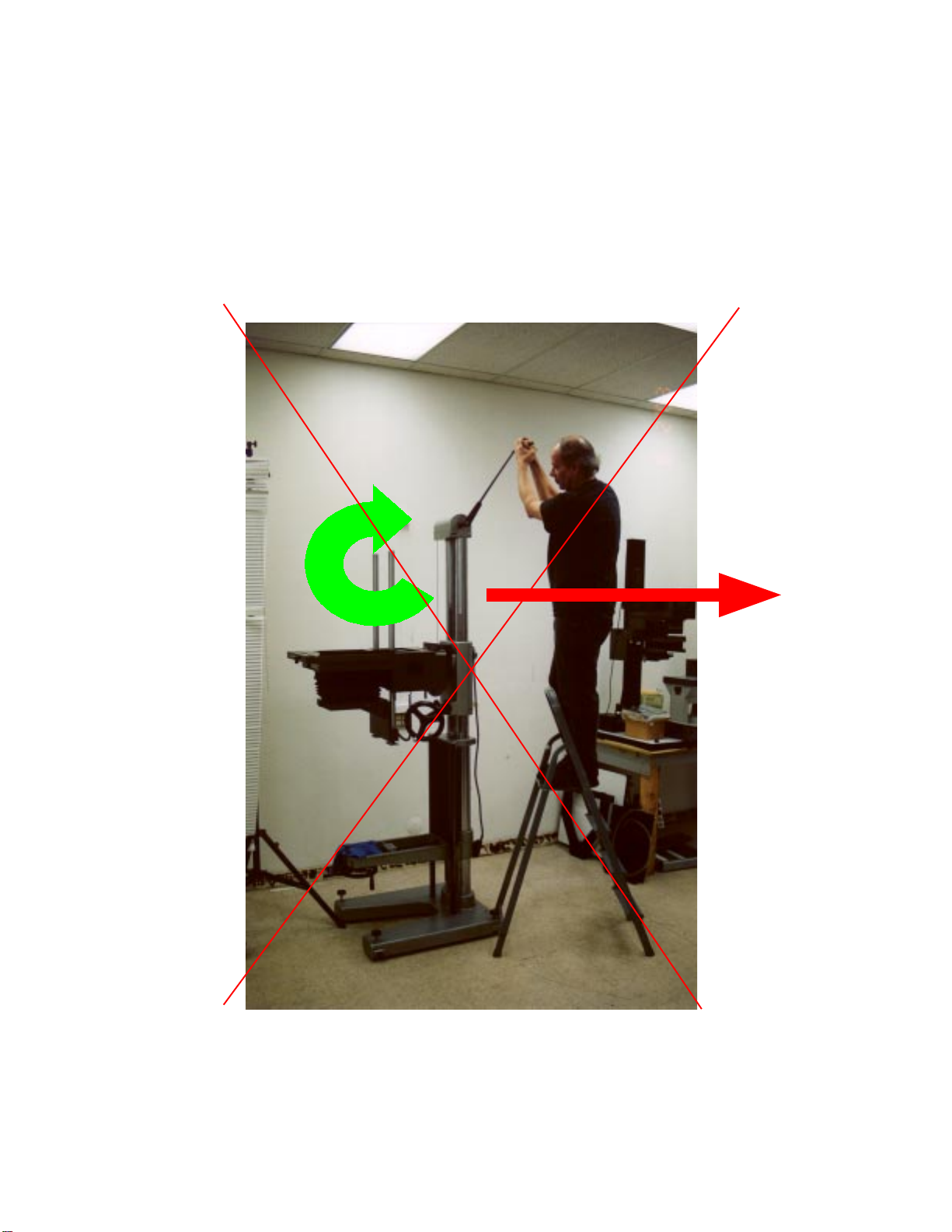

InordertoremovethecameraonanL184

it is only necessary to remove one screw.

When this screw is removed the camera

will slide off the support arm. Here it is

also helpful to be two persons, one per-

son to hold on to the chassis and one to

pull the camera off. The camera is quite

heavy, be careful not to drop it

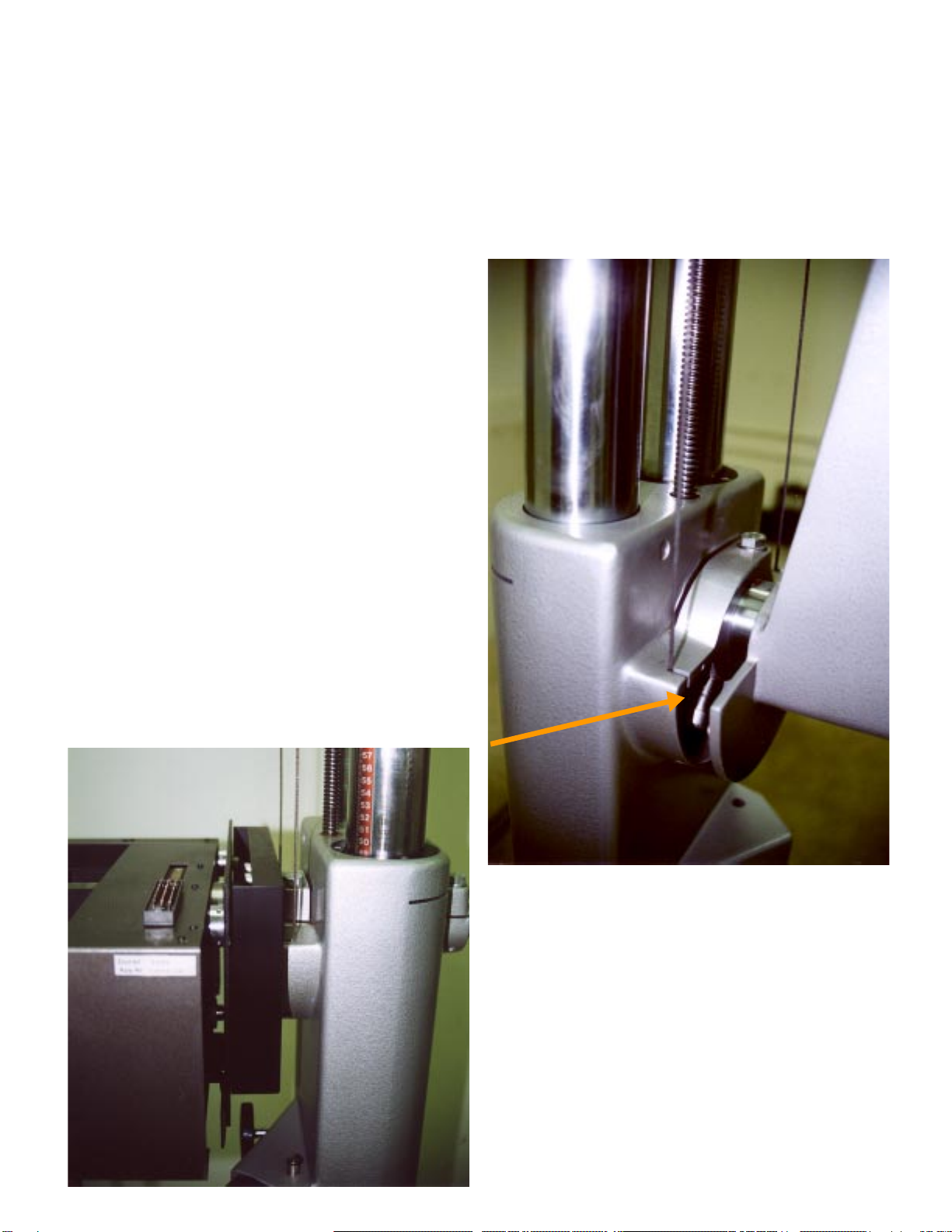

The tool kit consist off:

1. Tension tool - 4 foot wrench w/

handle and stop.

2. Bolt to secure tool to spring hous-

ing.

3. “C” shaped ¼” steel bracket

4. Wire brace tool.

If a replacement wire has been ordered

the wire kit will be enclosed with the

tools. It is metric wire. It is important to

use the right thickness wire,

The wire is coiled up inside the wire

wheel.

If the wire is to thin it will break, and

ruin the spring housing, if it is to thick it

will not fit inside the wire wheel. An ex-

cess thickness of less than one millime-

ter – less than 1/32” of one inch – will

prevent the right amount of wire fitting

inside the wire wheel.

Remove the cover from both sides of the

spring housing.