5

Important!

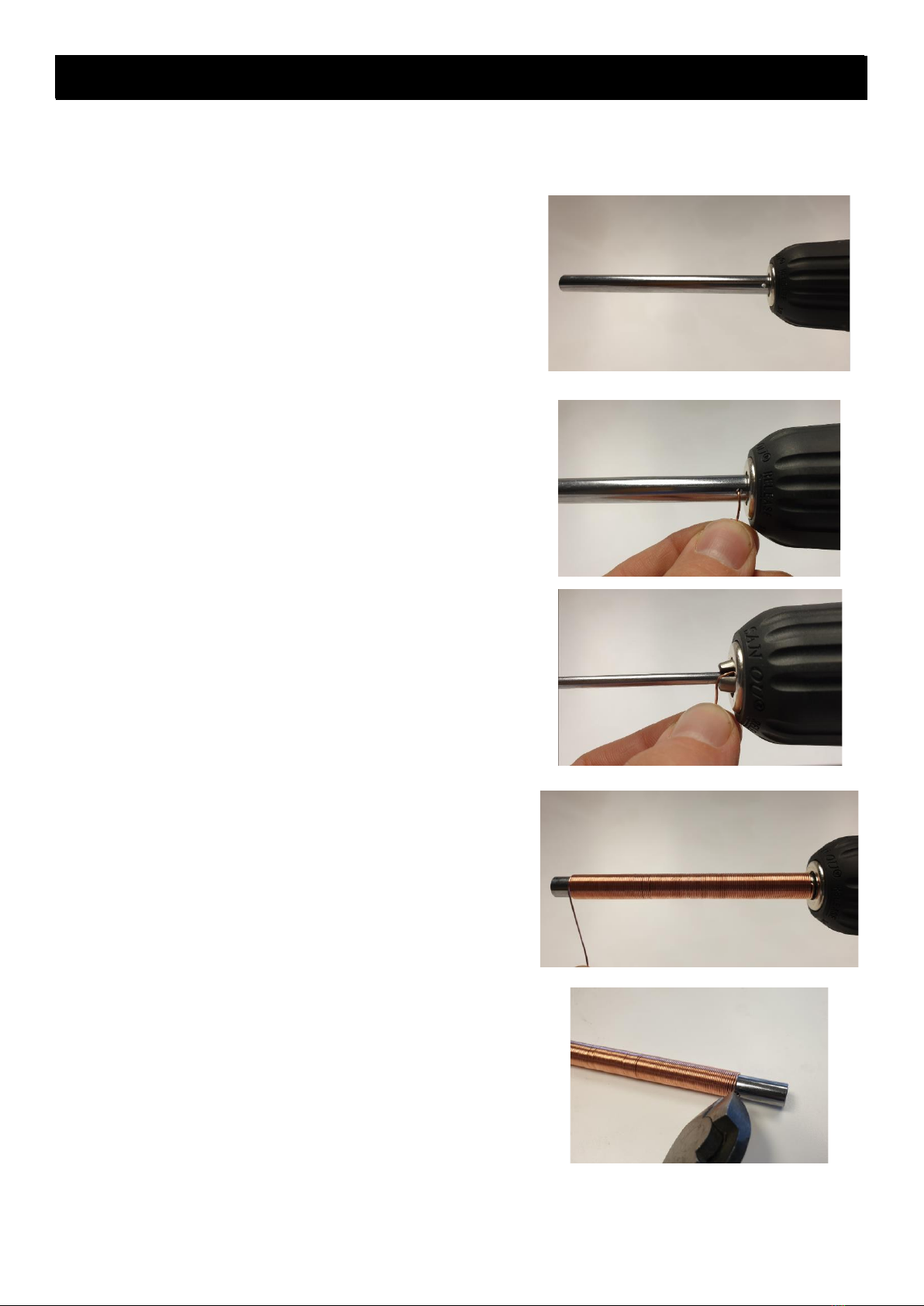

Hold the handpiece firmly and attach the flexshaft keeping

your hand and body clear of the blade.

Check that the motor is set to FORWARD (FWD).

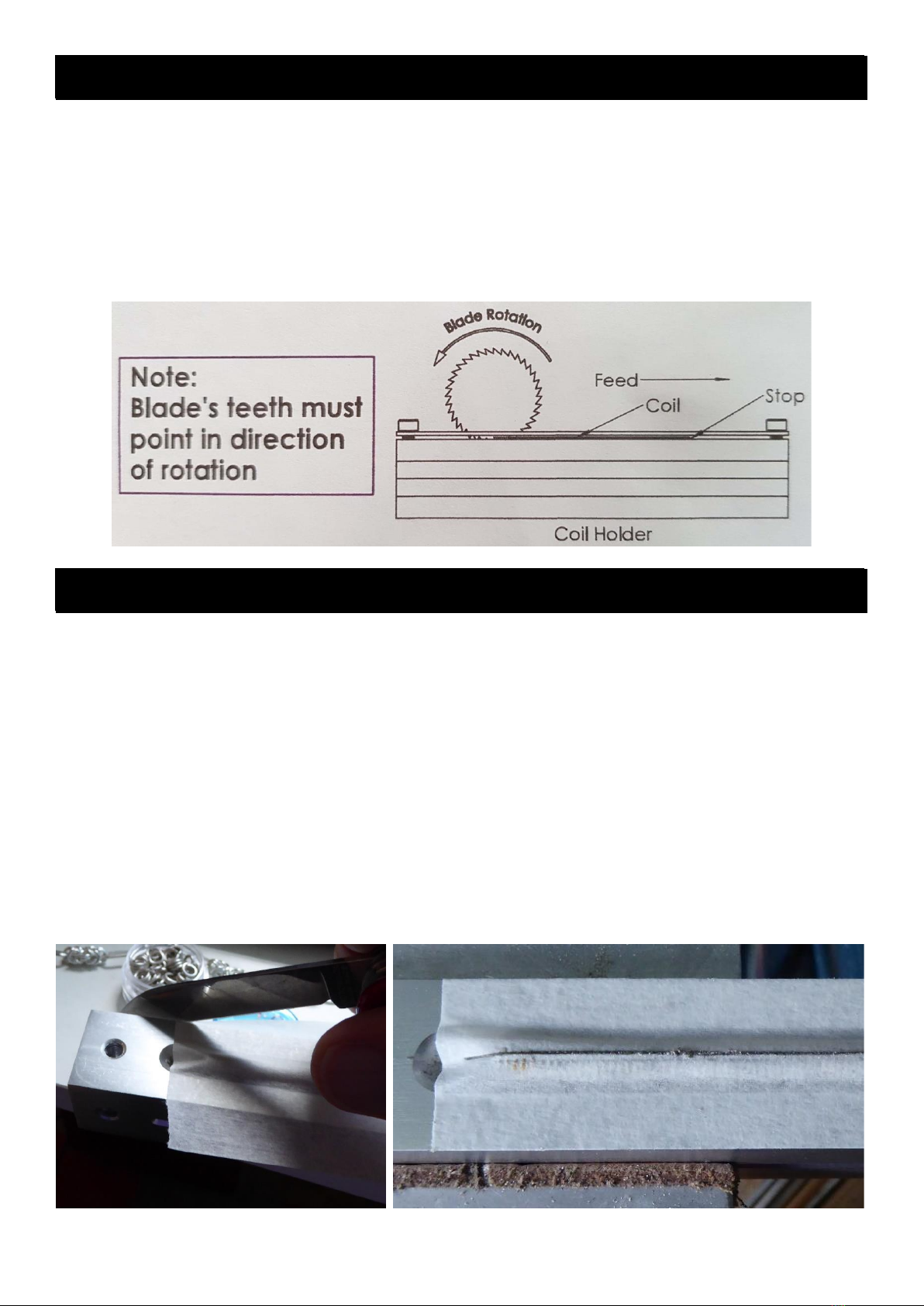

Position the handpiece and blade holder at the end of the

coil holder furthest from your body in your right hand. The

stop pin end is closest to your body.

Start the motor at a medium speed. Keep the handpiece

holder horizontal and press the handpiece holder against

the left-hand side of the coil holder. Using two hands pull

the handpiece holder towards you. Adjust the motor

speed (if using a foot control) to maintain a constant motor

speed. When you reach the end of the cut stop the motor.

Wait until it has stopped completely before removing it.

Carefully remove the handpiece from the flexshaft.

Note to left-handed users.

Complete the set up as described. This time you will put

the coil holder in the vice with the stop pin end furthest

away from you and handpiece in your left hand. Starting

at the end of the coil holder nearest to you, cut the coil by

pushing the flexshaft holder away from you.

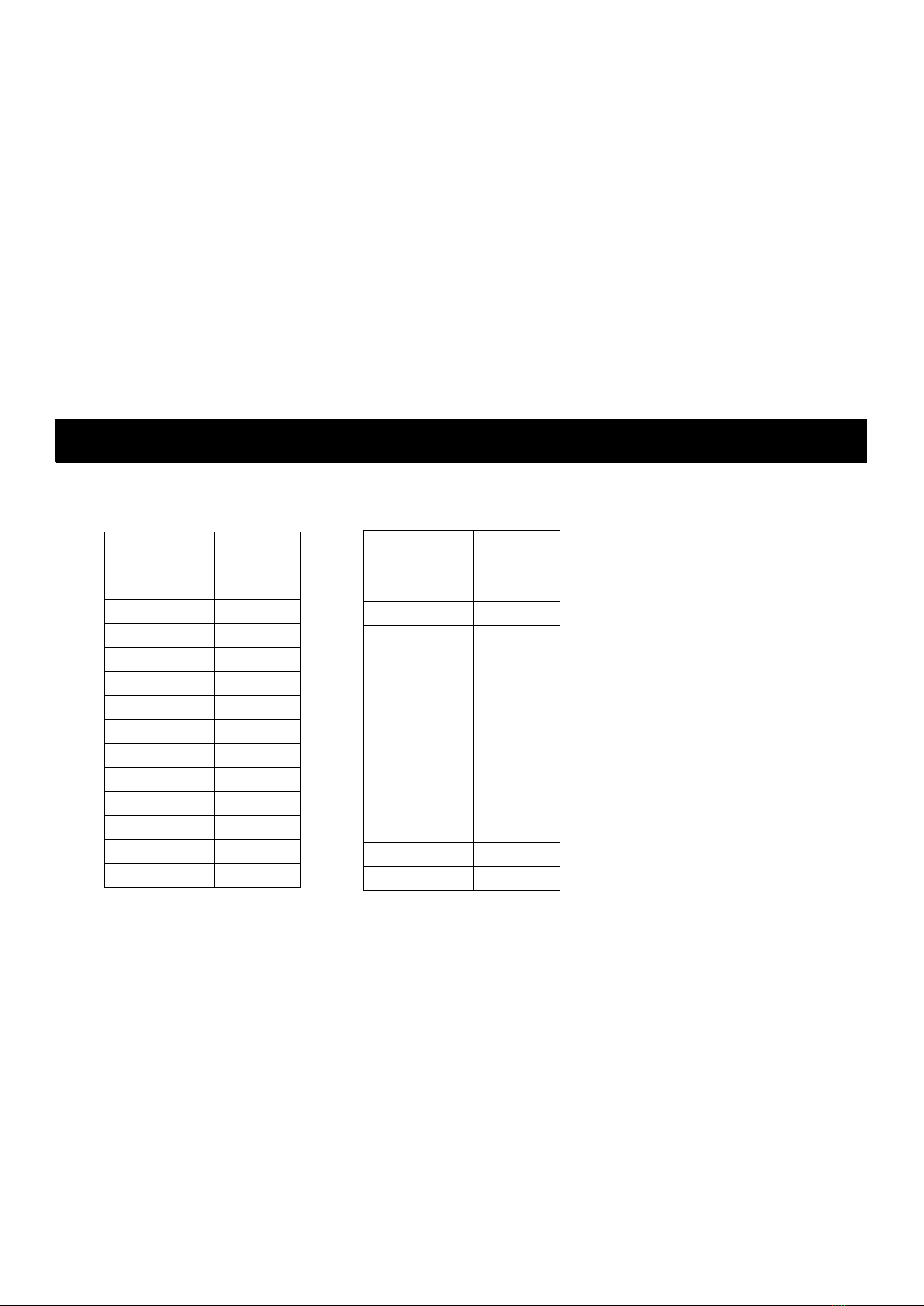

Finally, remove the jump rings from the coil holder.

The jump rings can be cleaned in an ultra-sonic cleaner and deburred in a tumbler as required. The jump rings

shown have an internal diameter of 4.5mm using 1mm sterling silver wire. A wooden dowel was used to

support the end of the coil at the end of the cut. The waste is shown on the right of the right-hand photo

below.