4Parts & Operations Manual DB Series

• Warning: If the machine is not working properly, has been dropped, damaged, left outdoors, or dropped into water,

return it to an Authorized service center.

• Warning: Damage could occur to machine if openings are blocked. Do not put any object into openings. Do not use

any opening blocked: keep free of dust, lint, hair, and anything that may reduce air flow.

• Warning: Injury could occur to the operator or the machine if used without the dust bag and/or filters in place. Do

not use the machine without the dust bag and/or filters in place.

• Warning: Injury to the operator and/or damage to the machine could occur when cleaning on stairs, unless caution

is used. Use extreme caution when cleaning on stairs.

• Warning: To reduce the risk of electrical shock, always use a 3-wire electrical system connected to the electrical

ground. Whenever possible connect the machine to an outlet protected by a ground fault interrupter (GFCI). See

“Grounding Instructions.”

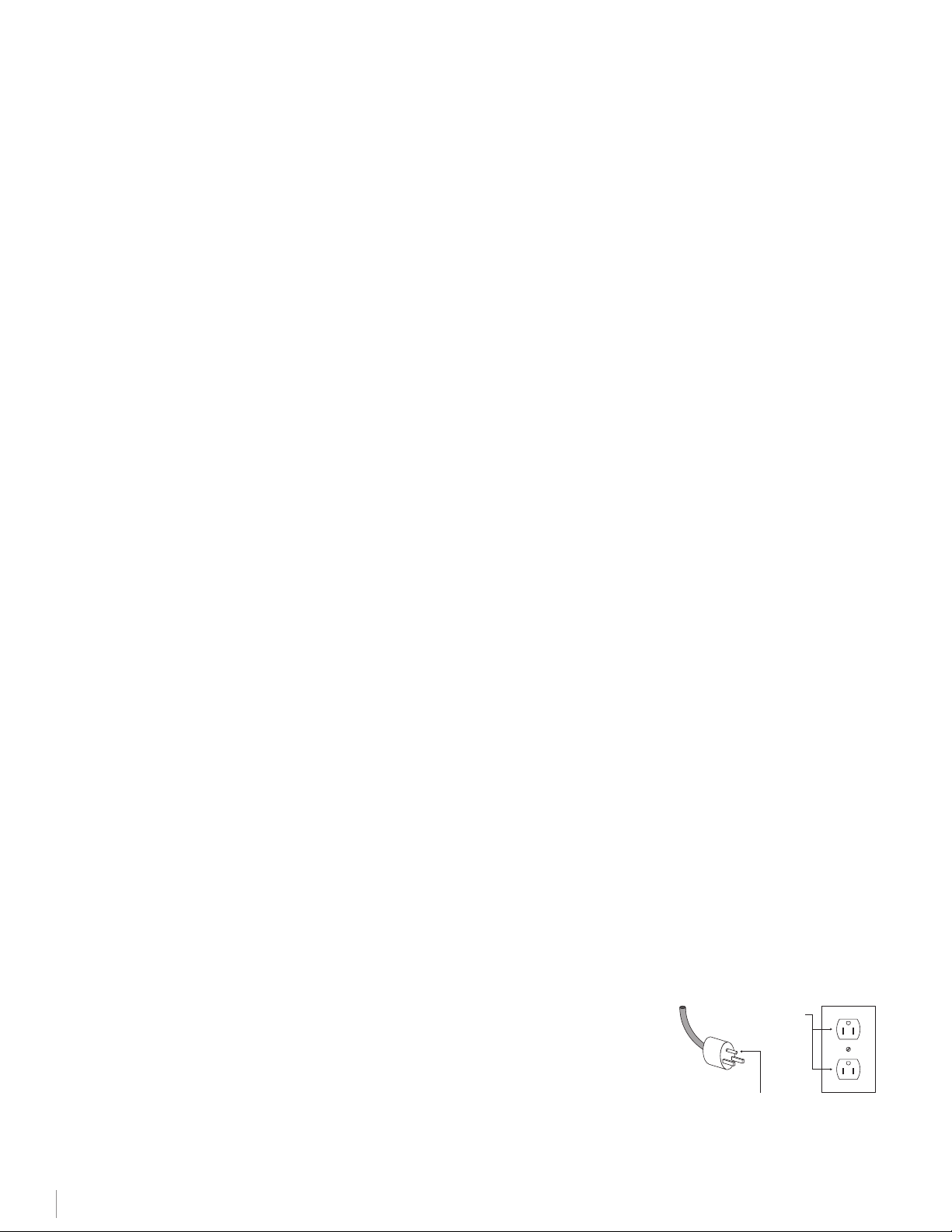

120 Volt Machine Instructions For Connection To The Power Supply And The Electrical Ground

(FOR DB4, DB7, AND DB24 MODELS)

This machine must be connected to the electrical ground to protect the operator from electrical shock. The machine has

an approved power cord with three conductors and a plug with three terminals. Connect the plug to a receptacle that has

three holes and is connected to the electrical ground. The green (or green and yellow) conductor in the cord is the ground

wire. Never connect this wire to any terminal other than the ground terminal.

This machine uses a 120 volt AC 60 cycle electrical circuit. Make sure you have the correct frequency and voltage before

connecting the power cord to an outlet. The machine has a plug as shown in Figure 1. If a receptacle connected to the

electrical ground as shown in Figure 1 is not available, have one installed by an electrical contractor. Do not use an adapter.

• Warning: To reduce the risk of electrical shock, protect the machine from rain. Keep the machine in a dry area.

• Warning: To reduce the risk of electrical shock, always use a 3-wire electrical system connected to the electrical

ground. Whenever possible connect the machine to an outlet protected by a ground fault interrupter (GFCI).

• Warning: Do not cut, remove or break the ground pin. If the outlet does not fit the plug, consult your electrical

contractor.

• Warning: Have worn, cut or damaged cords and plugs replaced by an authorized service person.

• Warning: If it becomes necessary to use an extension cord to reach an electrical outlet, you must use one that is at

least one size larger in wire size. Such as a power cord that is marked 12/3 would need to use an extension cord

that is marked 10/3. Do not use an extension cord that is undersized.

GROUNDING INSTRUCTIONS FOR DB4, DB7, AND DB24 MODELS

IMPORTANT: Improper grounding method can result in a risk of electrical shock. This equipment shall not be used with any

extension cord.

DB vacuums must be connected to a properly grounded outlet only. If it should malfunction or breakdown, grounding

provides a path of least resistance for electric current to reduce the risk of shock. DB vacuums are equipped with a cord

having an equipment-grounding conductor and grounding plug. The plug must

be inserted into an appropriate outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING: Improper connection of the equipment grounding conductor can result in a

risk of electric shock. Check with a qualified electrician or service person if you are in

doubt as to whether the outlet is properly grounded. Do not modify the plug provided

with the appliance – if it will not fit the outlet, have a proper outlet installed by a

qualified electrician. RATED LESS THAN 15AMPERES AND INTENDED FOR USE ON A

NOMINAL 120-VOLT SUPPLY CIRCUIT: the DB vacuums have a grounding attachment

plug that looks like the plug illustrated. Make sure that the vacuum is connected to an outlet having the same configuration

as the plug. No adaptor should be used withthese vacuums.

GROUNDING PIN

BRANCHE DE MISE À LA TERRE

GROUNDED OUTLET

PRISE DE COURANT

GROUNDING INSTRUCTIONS

DIRECTIVES DE MISE À LA TERRE