INDEX

1DISCLAIMER ......................................................................................................................................................................................2

2EU-DECLARATION OF CONFORMITY ..................................................................................................................................................3

3SAFETY INSTRUCTIONS AND WARNINGS ...........................................................................................................................................4

3.1 Water draining, packing, transport and storage instructions of DTE installations. .......................................................................5

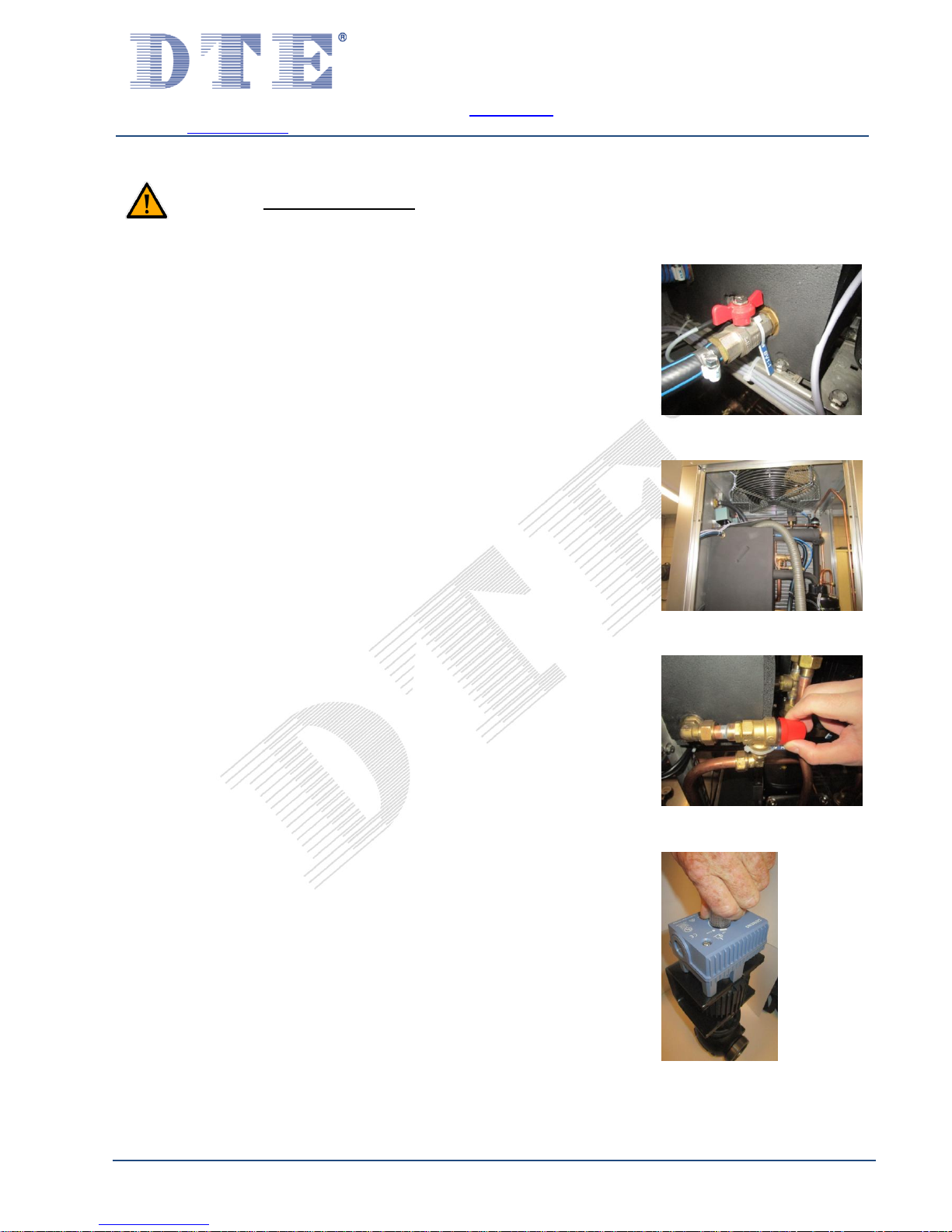

3.1.1 Draining water from the machine .............................................................................................................................................5

3.1.2 Packing, transport and storage instructions .............................................................................................................................7

3.2 Correct applications.......................................................................................................................................................................7

3.3 Application area ............................................................................................................................................................................7

4GENERAL DESCRIPTION .....................................................................................................................................................................8

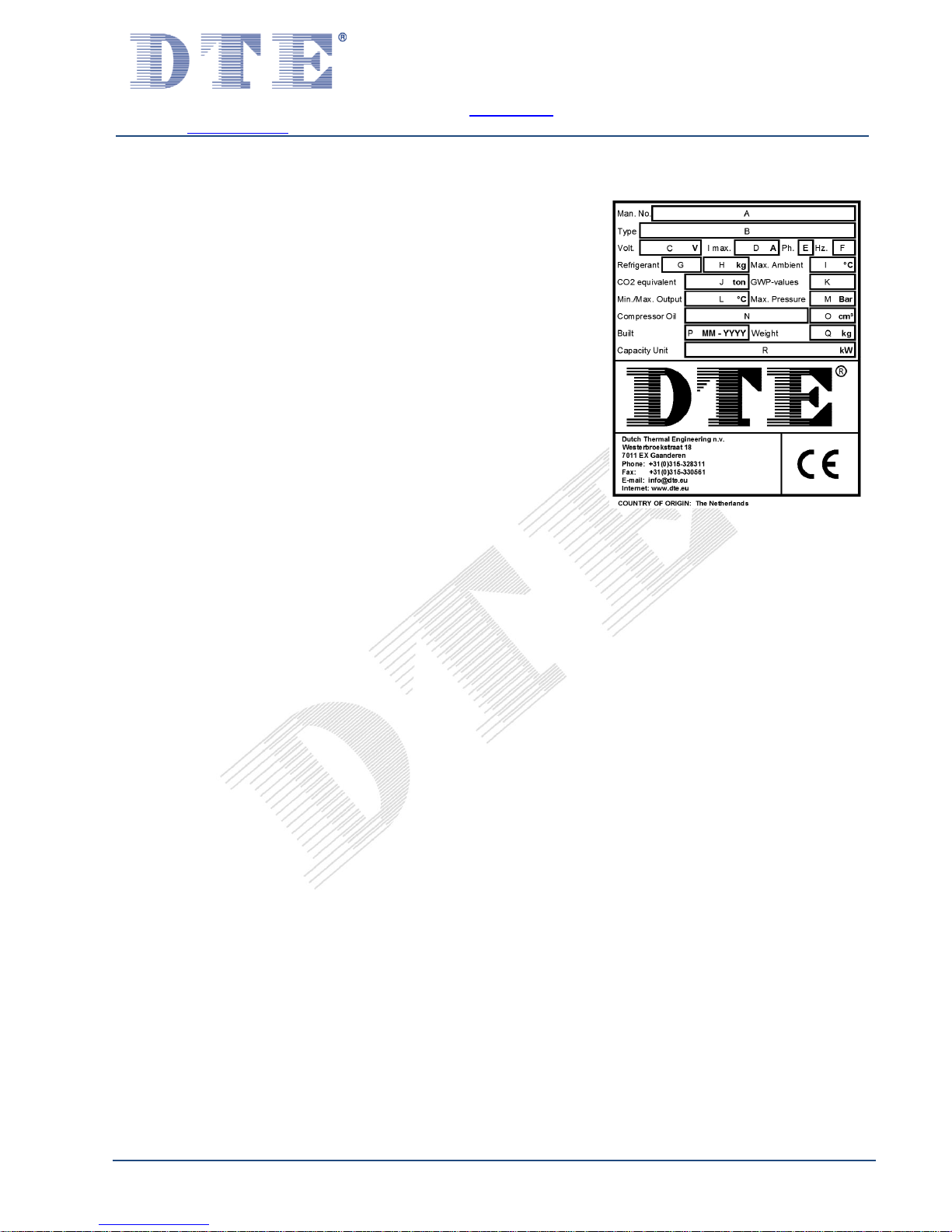

4.1 Identification..................................................................................................................................................................................9

5COMMISSIONING ............................................................................................................................................................................10

5.1 Connecting cooling water pipes...................................................................................................................................................11

5.2 Connecting overflow pipe ............................................................................................................................................................12

5.3 Connecting power supply............................................................................................................................................................. 12

5.3.1 Plug-in terminals .....................................................................................................................................................................13

5.4 Connecting external contacts ......................................................................................................................................................13

5.5 Water quality...............................................................................................................................................................................14

5.6 Filling of (external) pipes and systems CoolMaster (K) ................................................................................................................15

5.7 Filling of (external) pipes and systems CoolMaster (N)................................................................................................................ 16

5.8 Filling of the system CoolMaster (K) ............................................................................................................................................ 19

5.9 Filling of the system CoolMaster (N)............................................................................................................................................20

5.10 Deaerating...................................................................................................................................................................................21

5.11 Setting thermostat....................................................................................................................................................................... 22

5.12 Commissioning after long standstill ............................................................................................................................................23

6MEANING OF ALARMS (IF APPLICABLE) ...........................................................................................................................................24

7FAULT ANALYSIS..............................................................................................................................................................................25

8MINIMUM INSPECTION-INTERVAL SCHEME.....................................................................................................................................26

9CLEANING OF THE MACHINE............................................................................................................................................................27

10 CHECKS .......................................................................................................................................................................................27

11 SERVICE.......................................................................................................................................................................................27

12 GUARANTEE ................................................................................................................................................................................28

13 REMOVAL....................................................................................................................................................................................28

14 APPENDIX ...................................................................................................................................................................................29

14.1 Options ........................................................................................................................................................................................30

14.2 Connection diagram filling the system ........................................................................................................................................31

14.3 Watertreatment ..........................................................................................................................................................................32

14.4 Guidline for water quality in DTE installations............................................................................................................................. 33

14.5 User manual thermostat.............................................................................................................................................................. 34

14.6 Safety information sheets............................................................................................................................................................37

14.7 Comments....................................................................................................................................................................................45

14.8 Technical information.................................................................................................................................................................. 46

* Specification list ..................................................................................................................................................................................... 46

* Machine drawing ...................................................................................................................................................................................46

* Parts list .................................................................................................................................................................................................46

* Flow scheme ..........................................................................................................................................................................................46

* Electrical scheme....................................................................................................................................................................................46

* User manual thermostat........................................................................................................................................................................46

* Safety data sheet refrigerant.................................................................................................................................................................46

* Other...................................................................................................................................................................................................... 46