For customer service call 888.389.2732 Page 2

PLATINUM PRESSURE FEED

The DUX Platinum Pressure Feed

INSPIRED BY FORMULA RACE CAR

ENGINES.

Once again, DUX has reinvented the spray gun

from the inside out! Built upon the success of the

original DUX Pressure Feed spray gun, the new

“Platinum” series gun is the next step for-ward in

spray gun evolution. We’ve maintained our pat-

ented Advanced Laminar Airow technology, but

we’ve added more user friendly features and a new

coating with embedded PTFE for easier cleaning

and longer parts life.

As always, nishers can spray nearly any type of

uid, onto nearly any surface with a single gun,

while reducing coatings waste and improving nish

quality.

TECHNOLOGY THAT’S EASY TO USE

AND EASY ON US.

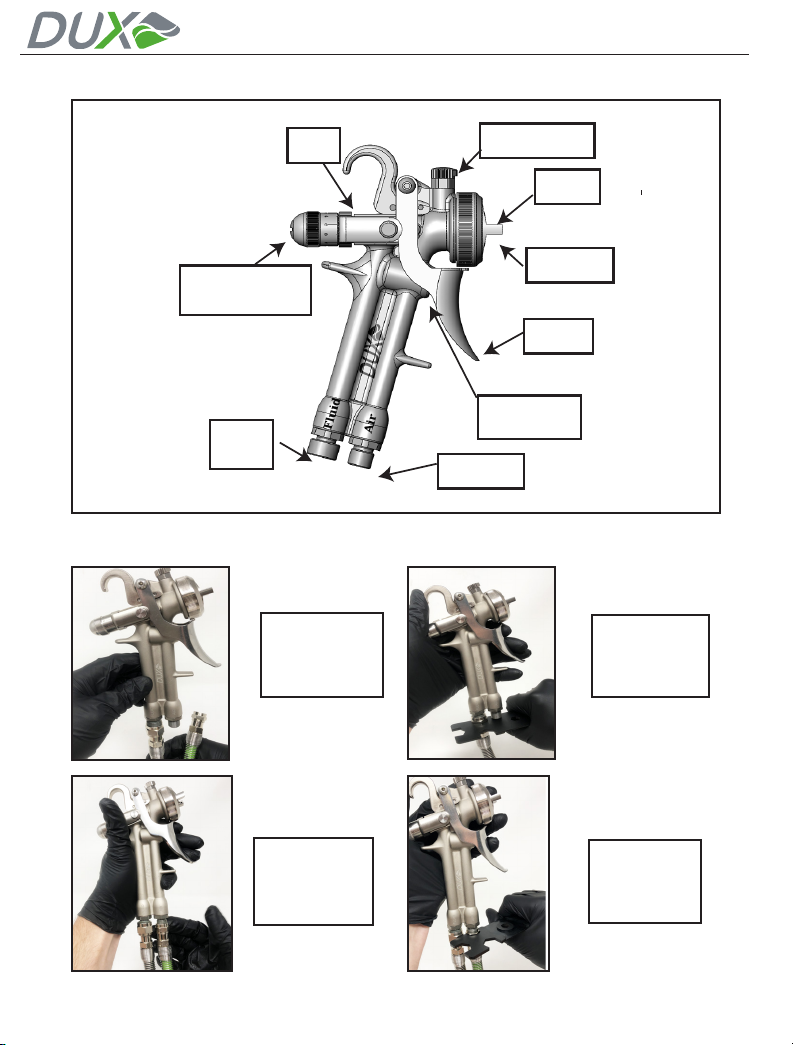

Most pressure feed spray guns incorporate a front-

heavy body design with uid hose connections

near the tip of the gun. Over the course of a long

work day, the extra weight causes arm fatigue and

uneven spray patterns that impact nish quality.

The DUX Platinum Pressure Feed gun, however,

is designed with much shorter air passages, an

upright handle, and uid and air connections lo-

cated at the base of the gun. This creates a lighter,

more compact and balanced gun that’s easier to

maneuver in small spaces.

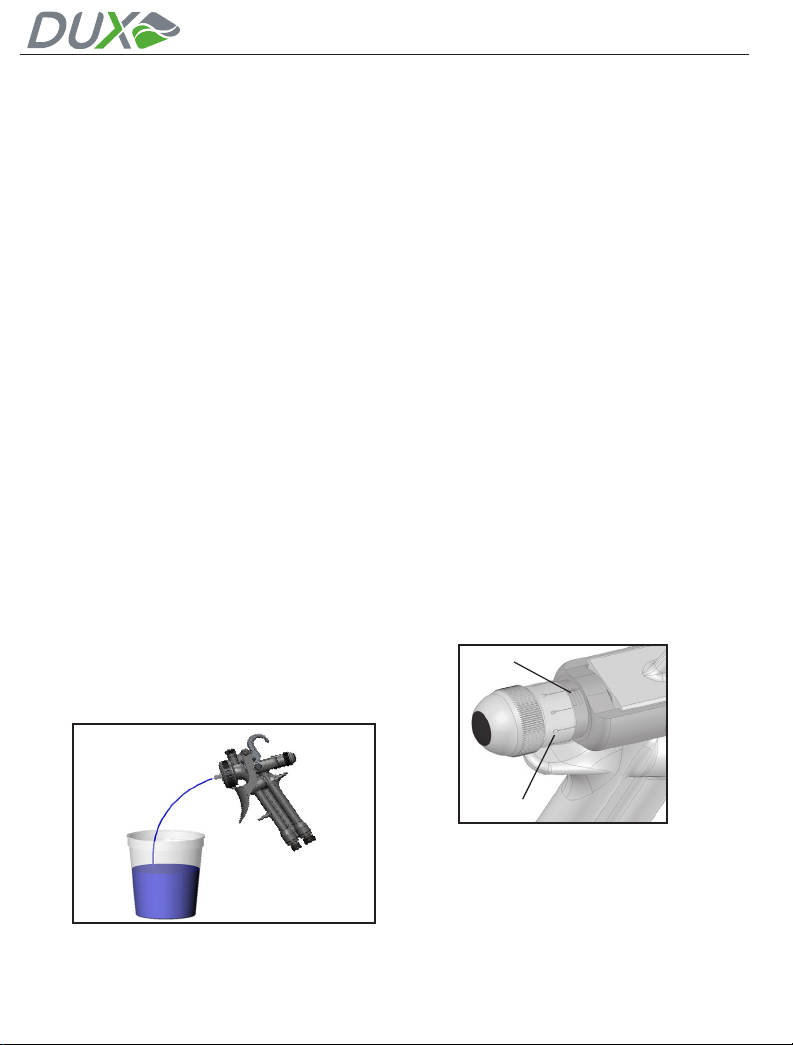

Lower operating pressures also result in mas-

sive reductions of unhealthy paint booth fog and

overspray. This drastically improves the work

environment for everyone involved.

Patent Information

The design and technology forming the basis

of this product is the condential information of

DUX Technologies Inc., a Washington corpora-

tion. The relevant US Patent Numbers are: US

6,793,157; US 6,425,533, and U.S. 7,004,404.

DUX Technologies Inc. may have additional

patents, patent applications, trademarks,

copyrights, or other intellectual property rights

covering subject matter in this document.

Except as expressly provided in any written

license agreement from DUX Technologies Inc.,

this document does not grant you any license

to or rights in any such patents, trademarks,

copyrights, or other intellectual property.

© 2018 DUX Inc. All rights reserved.

DUX, DUX, DUX Pressure Feed, and DUX

Platinum Pressure Feed are either registered

trademarks or trademarks of DUX Technologies

Inc. in the United States and/or other countries.

Please note that your Pressure Feed

Spray Gun was shipped with the follow-

ing contents:

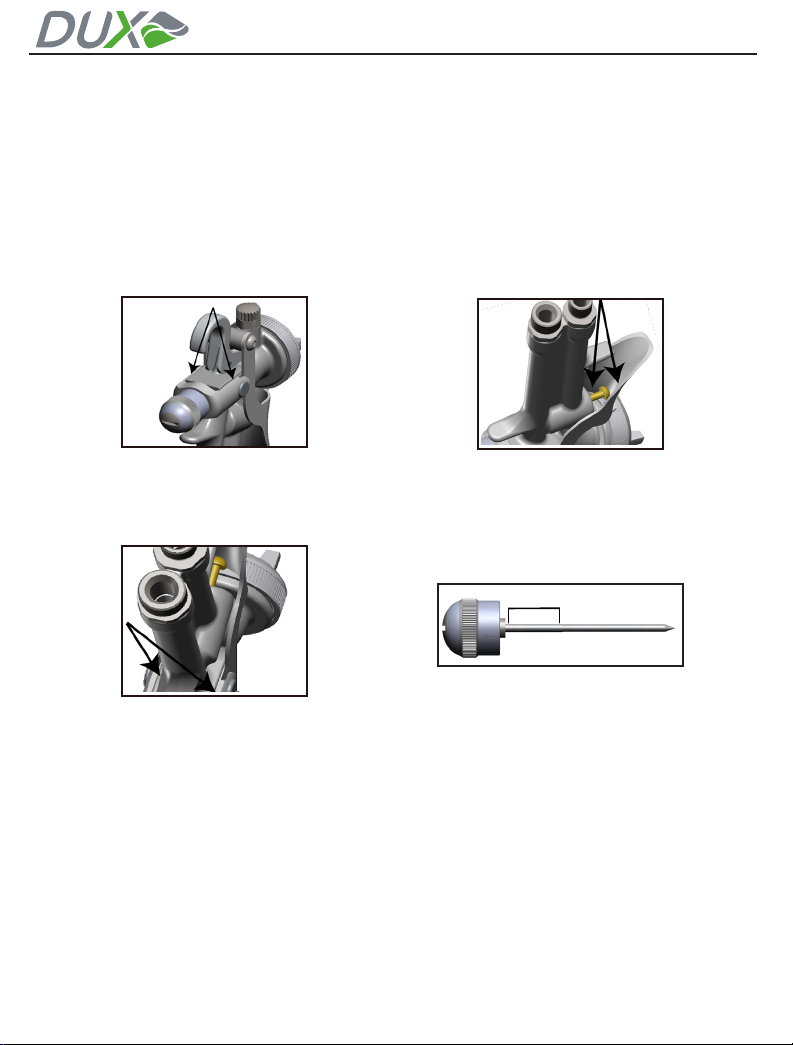

• Pressure Feed Spray Gun

• Fluid Tip

• Air Cap

• PTFE Grease Lubricant

• Dux Multi-Tool

• Cleaning Brushes

•

If anything is missing or you would like to

order additional parts, please contact Dux at:

Dux Technologies, Inc.

P.O. Box 1314

Seahurst, WA 98062

Tel: 888.289.2732

Fax: 888.876.1233

Website: www.DuxTechnologiesInc.com

Email: Customer.Service@DuxTechnologiesInc.com