H40, H50, H50VSD-C

Jul ‘17

- 6 -

Safety Precautions

In order to operate the Compressor Unit safely and correctly, we have opted to use the following symbols to make

you aware of important points. These points relate to user safety and preventing equipment problems. Please pay

close attention to these sections.

The following hazards may occur during the normal use

of the equipment. Please read the following chart.

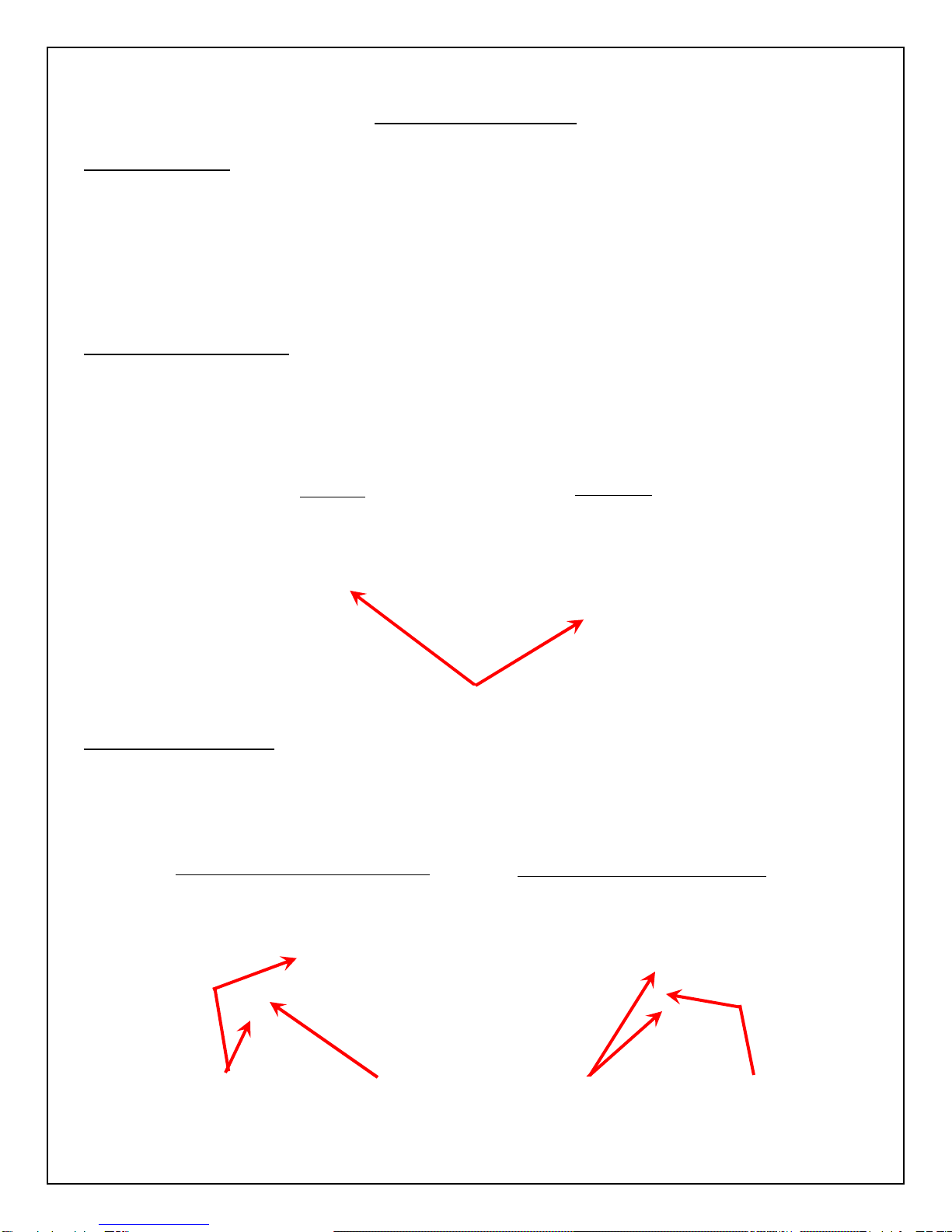

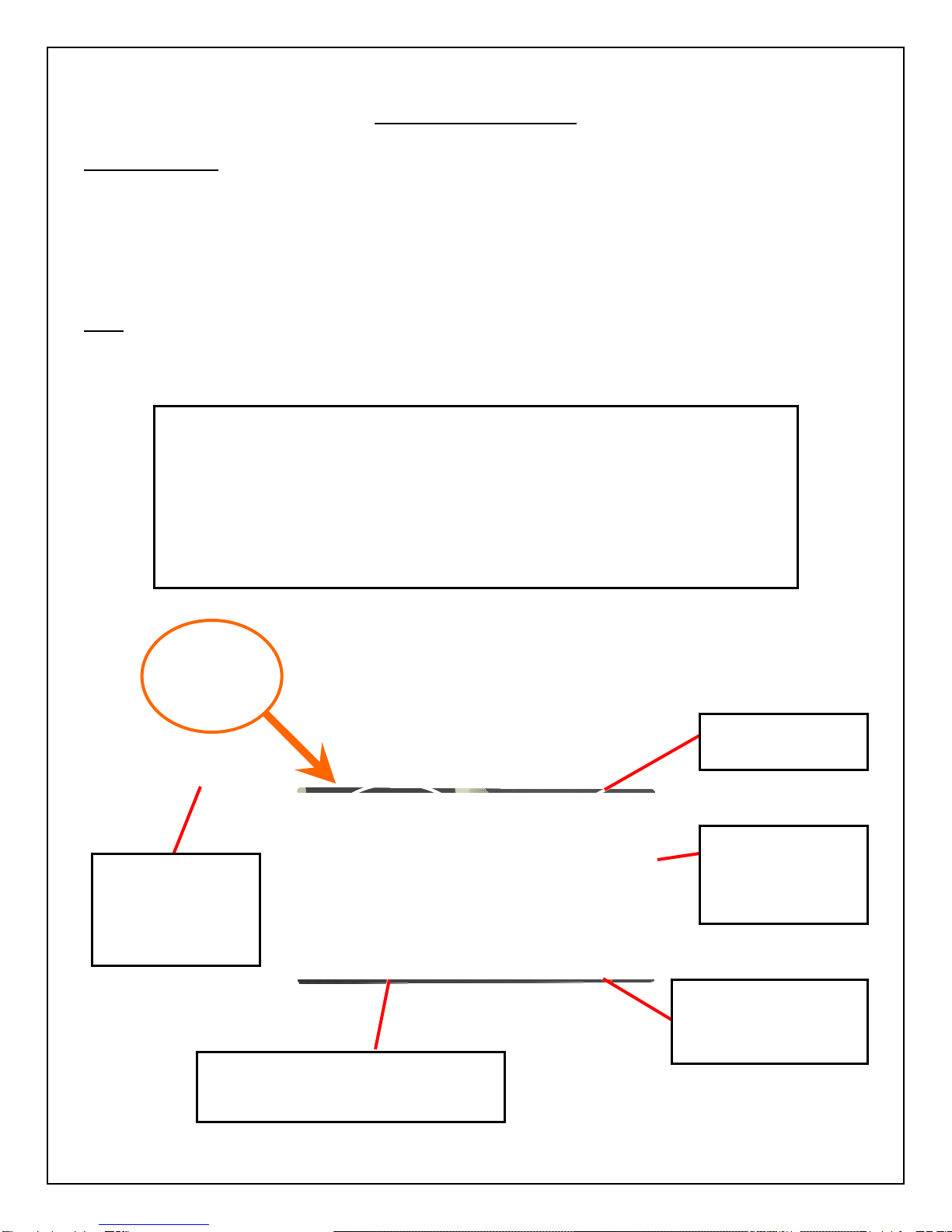

Area: Hazard: Safeguards:

What to look for: What may occur if precautions are not observed. How to avoid the hazard.

Tampering with the Unit while under full or partial

pressure may cause an explosion.

Relieve all pressure from the Unit

before attempting any repair or

maintenance work.

As the Unit starts and stops automatically, serious

injury may result from working on the Unit with the

power still in the on position.

Shut off all power to the Unit before

attempting any repair or maintenance

work.

As the Unit starts and stops automatically, do not

come into contact with moving parts.

Shut off all power to the Unit before

attempting any repair or maintenance

work.

Air compressed by the Unit is not suitable for

inhaling. It may contain vapours harmful to your

health.

Never directly inhale compressed air

produced by the Compressor.

The Compressor Pump, Motor, and Tubing

become hot when running. Touching these areas

may cause severe burns.

Never touch the Pump, Motor, or

Tubing during or immediately after

operation.

As the electrical components on the Unit are

General Purpose, there is a potential for explosion

should vapours be present in the area.

The Compressor must be a minimum

of 20 feet (6.1 meters) from any source

of potentially explosive vapours.

Important safety Information.

A hazard that may cause

serious injury or loss of life.

Important information that

indicates how to prevent

damage to equipment, or how

to avoid a situation that may

cause minor injury.

Information that you should

pay special attention to.