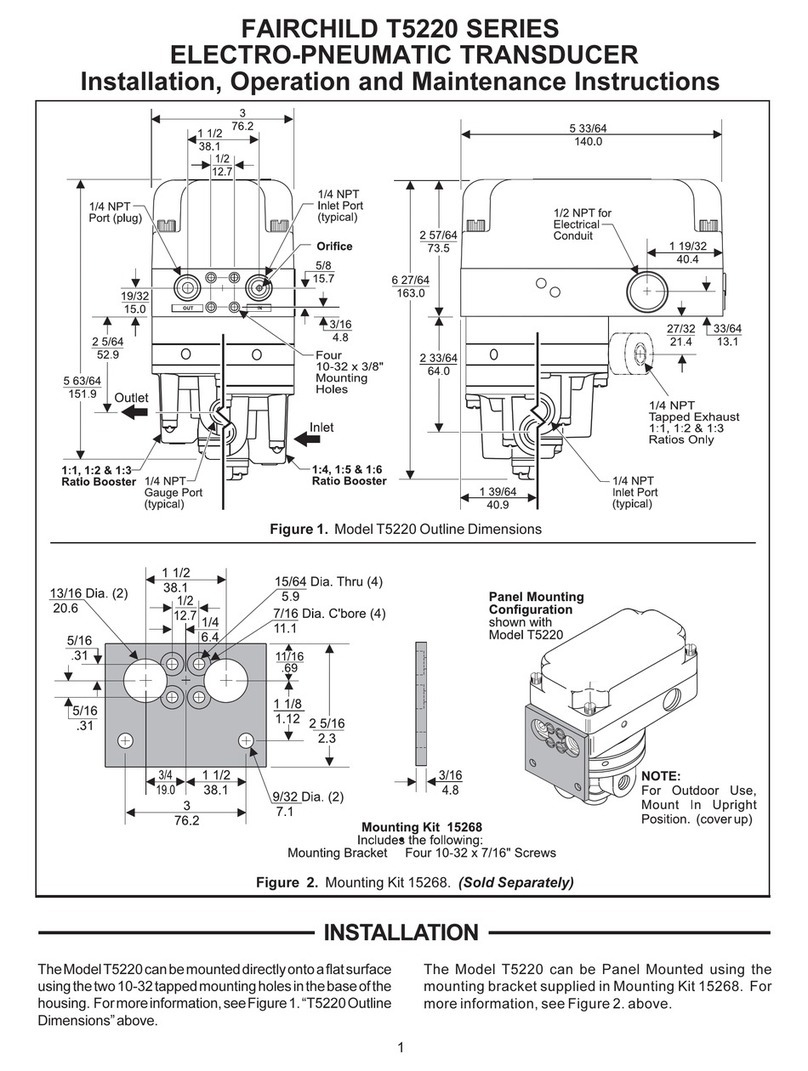

3

Cleanallpipelinestoremovedirtandscalebeforeinstallation.Apply

a minimum amount of pipe compound to the male threads of the

fittingonly. DoNotuseteflontapeasasealant. Startwiththethird

thread back and work away from the end of the fitting to avoid

contaminating the transducer. Install the transducer in the air line.

Theinletandoutletportsarelabeledontheendsof thetransducer.

Tightenconnectionssecurely. Avoidundersizedfittingsthatwilllimit

the flow through the transducer and cause pressure drop down

stream.

Electric Connection

Make connections as shown in Figure 8.

Pneumatic Connection

NOTE: Oil free air is required. Use a filter to remove dirt and

liquid in the air line ahead of the transducer. If an air

line lubricator is used, it MUST be located down-

stream to avoid interference with transducer perfor-

mance.

The user is responsible for insuring that the environ-

ment in which the unit will be installed and the

operatinggasarecompatiblewiththematerialsinthe

transducer.

1.

2.

3.

Shut off the valve that is supplying air to transducer.

It is not necessary to remove the Transducer from

the air line.

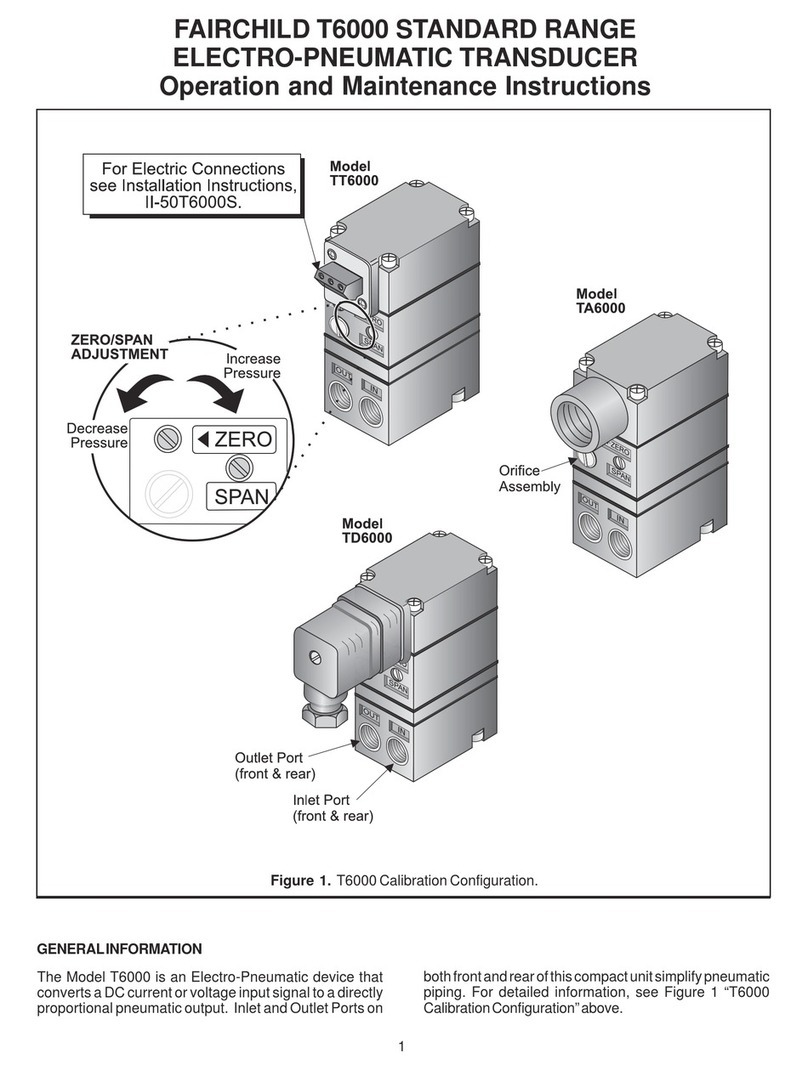

Remove the Orifice Assembly from the unit. For

detailed information see Figure 1 “T6100 Calibration

Configuration on page 1.

Clean with alcohol and dry with compressed air.

To clean the Orifice, use the following procedure:

MAINTENANCE

Parts must be completely dry before reassembling.

If the standard maintenance procedure does not

correct the trouble, install the appropriate Service

Kit below:

20781-1

Service Kits also include Gasket, O-Rings, and

Membranes to replace "W" Option product.

NOTES:

The information set

forth in the foregoing

Operation and Mainte-

nance Instructions

shall not be modified

or amended in any re-

spect without prior

written consent of

Fairchild Industrial

Products Company. In

addition, the informa-

tion set forth herein

shallbefurnishedwith

each product sold in-

corporatingFairchild's

unit as a component

thereof.

LEGAL NOTICE:

Figure 8.

1

TROUBLE-SHOOTING

Table 1. Trouble-Shooting.

Problem Solution (check)

Supply Pressure

Clogged Orifice

Input Signal

Pneumatic Connections

Zero and Span Adjust

Supply Pressure Low

OutputLeakage

DC Signal

Loose Wires or Connections

Liquid in Air Supply

Dirt in Magnet Gap

NoOutput

Leakage

Low or Improper

SpanAdjust

Erratic Operation

Failure of Transducer could result in out-

put pressure increasing to supply pres-

sure possibly causing personal injury or

damage to equipment.

WARNING:

SPLIT RANGE OPERATION

All units have the capability to be split ranged or set for any

output in the range as long as the Output Span is equal to

or greater than the minimum Span.