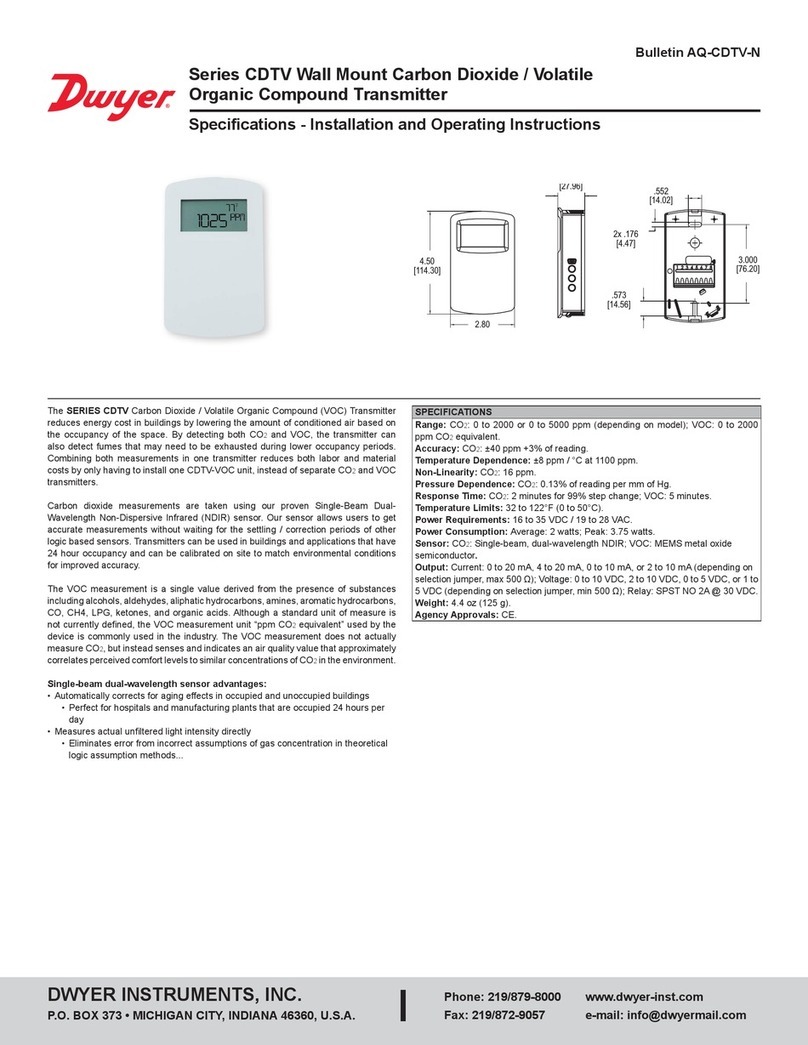

ELECTRICAL CONNECTIONS

CAUTION: DO NOT EXCEED SPECIFIED SUPPLY VOLT-

AGE RATINGS. PERMANENT DAMAGE NOT COVERED

BY WARRANTY WILL RESULT. THIS UNIT IS NOT

DESIGNED FOR AC VOLTAGE OPERATION.

Electrical connections to the Series 605 Transmitter are

made to the two-screw terminal strip on the rear of the

case. Polarity is indicated by + and – signs stamped on

side. The schematic diagram of the Series 605 transmitter

is illustrated in Figure B.

in series with the current loop but in parallel with the receiv-

er input. Referring to Figure B, RLbecomes the 250 ohm

resistor and point X and Y are connected to the receiver

input, point X being positive (+) and point Y negative (–) or

ground. The resistor should be connected at the panel end

of the transmitter current loop close to the receiver input to

take advantage of the immunity of the current loop to elec-

trical noise pickup. Most electronic component distributors

stock a 249 r, 1/2 watt, ±1% tolerance metal film resistor

which is adequate for this application.

An external power supply delivering 10.0 to 35 VDC with a

minimum current capability of 40 milliamps must be used to

power the control loop in which the Series 605 transmitter

is connected. Refer to Fig. B for connection of the power

supply, transmitter and receiver. The range of appropriate

receiver load resistances (RL) for the power supply voltage

available is given by the formula and graph in Fig. C.

Shielded two wire cable is recommended for control loop

wiring and the negative side of the loop may be grounded

if desired. Note also that the receiver may be connected in

either the negative or positive side of the loop, whichever is

most convenient. Should polarity of the transmitter or

receiver be inadvertently reversed, the loop will not function

properly but no damage will be done to the transmitter.

SERIES 605

PRESSURE

TRANSMITTER

POWER

SUPPLY

10.0-35 VDC

RECEIVER (RL)

SEE FIG. C

NOTE: RECEIVER MAY BE IN

SERIES WITH + OR -

LEG OF CONTROL LOOP

The maximum length of connecting wire between the trans-

mitter and the receiver is a function of wire size and receiv-

er resistance. That portion of the total current loop resis-

tance represented by the resistance of the connecting wires

themselves should not exceed 10% of the receiver resis-

tance. For extremely long runs (over 1,000 feet), it is desir-

able to select receivers with higher resistances in order to

keep the size and cost of the connecting leads as low as

possible. In installations where the connecting run is no

more than 100 feet, connecting lead wire as small as No. 22

Ga. can be used.

The Series 605 transmitters can be used with receivers

requiring 1-5 volt input rather than 4-20 mA. If the receiver

requires a 1-5 volt input, insert a 250 ohm, 1/2 watt resistor

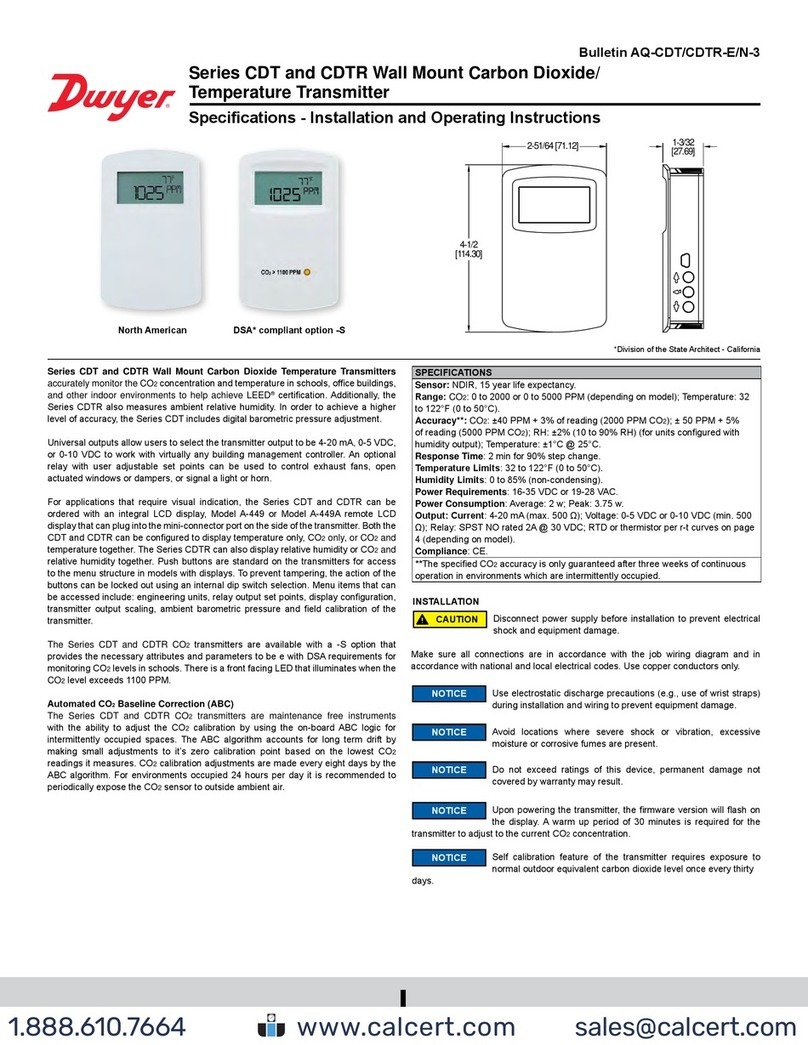

1400

1300

1200

1100

1000

900

800

700

600

500

400

300

200

100

05101520 25 30 35 40

RECEIVER RESISTANCE RL()

POWER SUPPLY VOLTAGE - VDC

RL MAX = VPS - 10.0V

20 mA DC

MAXIMUM VALUE (1250)

OPERATING

REGION

OUTPUT RANGING

Each Series 605 Magnehelic®indicating transmitter is fac-

tory calibrated to produce 4 mA at zero scale reading and

20 mA at full scale reading. The following procedure should

be used if the pressure versus output signal relationship

needs to be checked.

1. With unit connected to the companion receiver per pre-

ceding instructions, insert an accurate milliammeter

with a full scale reading of approximately 30 mA in

series with the current loop.

2. Vent both pressure ports to atmosphere and, if neces-

sary, adjust pointer zero screw to align pointer with zero

on scale. A controllable pressure source capable of

reaching the full scale range should be connected to

either high pressure port. Plug the other high pressure

port and vent one or both low pressure ports to atmos-

phere. The instrument must be ranged in the same

position in which it will be used. Standard factory cali-

bration and ranging is done with unit vertical.

3. Apply electrical power to the system and check for

proper operation by slowly increasing pressure and

observing whether the loop current increases above

the 4 mA zero pressure reading.

4. A spanner type key is supplied to adjust span and zero.

This helps to reduce unauthorized tampering. Apply

pressure until pointer aligns with full scale reading and

adjust the SPAN knob for a 20 mA reading.

Figure A

Figure B

Figure C

E-68 8/2/07 8:43 AM Page 3