2

Contents

Usage for the intended purpose ..............................................................................................................5

Safety Note.............................................................................................................................................5

Danger ...................................................................................................................................................5

ATEX (Atmosphère Explosible).................................................................................................................5

Note on the Declaration of Conformity / Declaration by the Manufacturer ..........................................5

Important Notes

Page

Explanatory Notes

Scope of supply......................................................................................................................................6

Description .............................................................................................................................................6

Function ............................................................................................................................................. 6, 7

Installation notes ..................................................................................................................................16

Attention...............................................................................................................................................16

Note .....................................................................................................................................................16

Mounting conductivity transmitter.........................................................................................................16

Installation

Electrical Connection

Technical Data

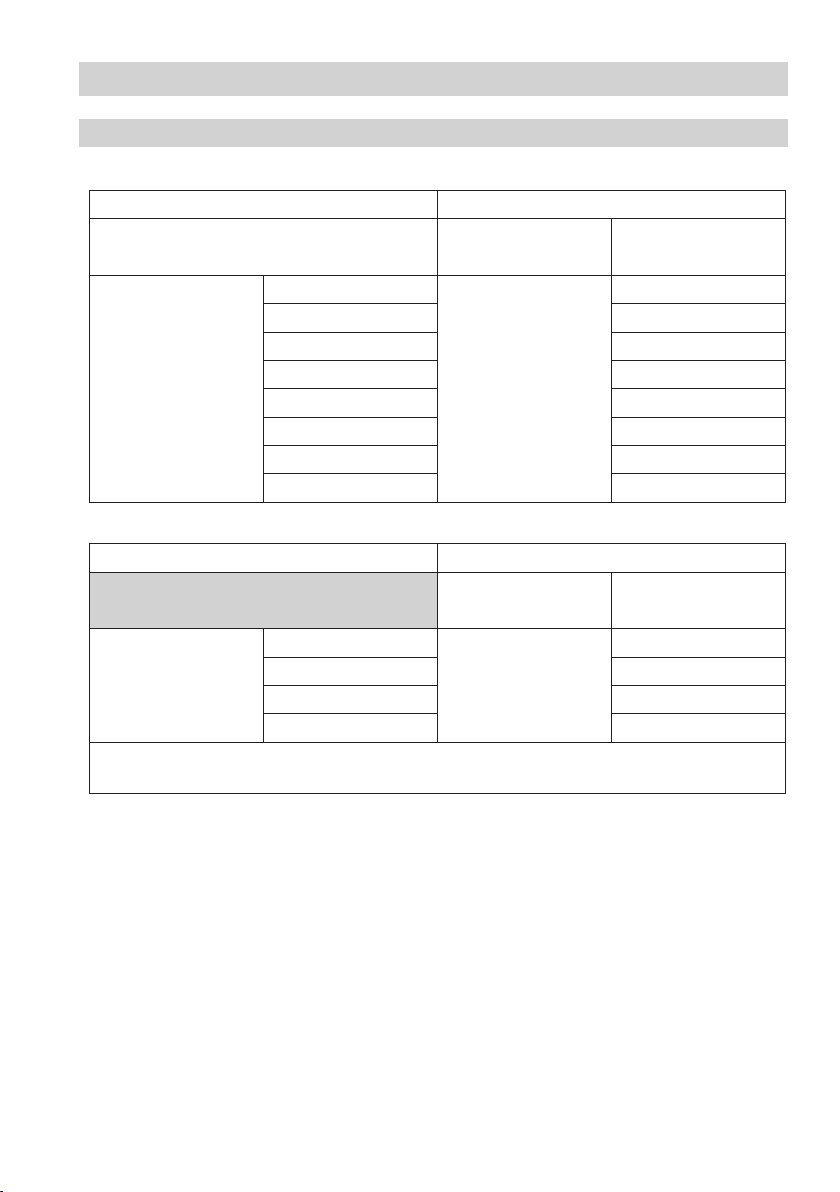

LRGT 16-1, LRGT 16-2, LRGT 17-1..................................................................................................... 8, 9

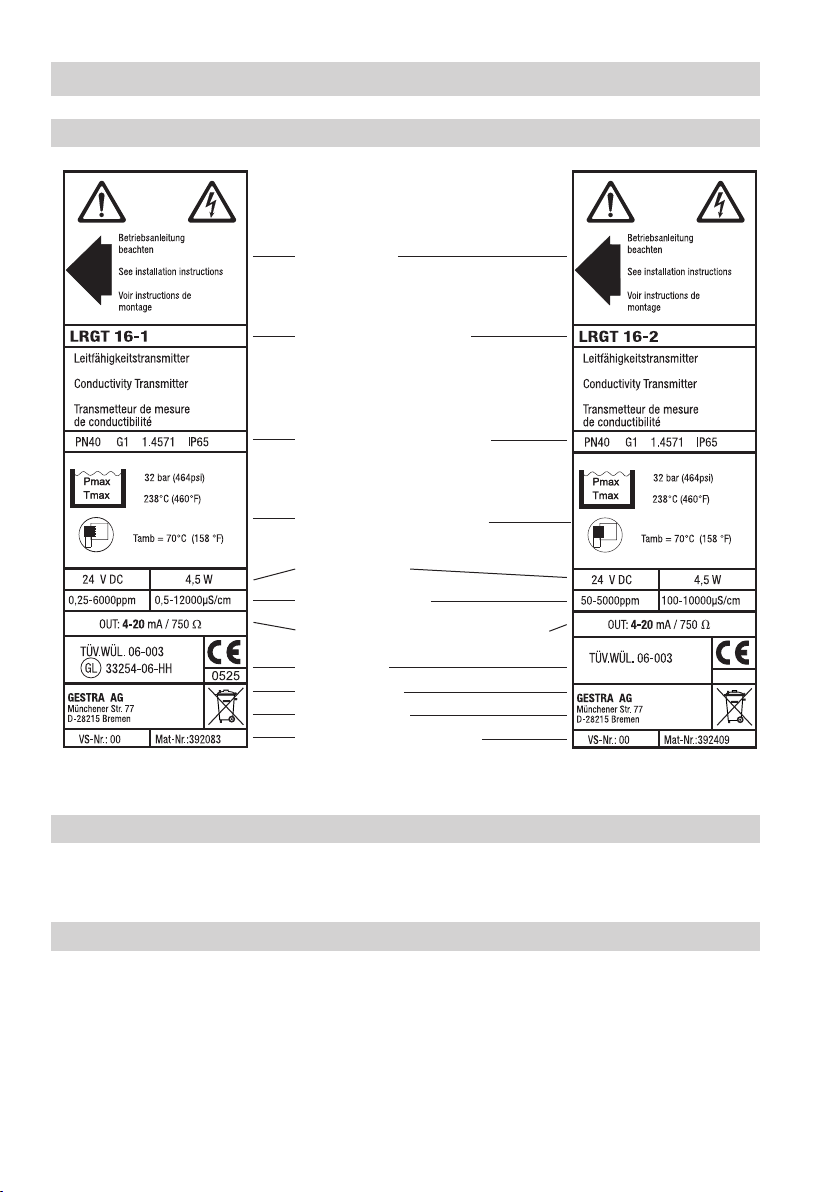

Name plate / marking ...........................................................................................................................10

Corrosion resistance.............................................................................................................................10

Sizing ...................................................................................................................................................10

Dimensions...................................................................................................................................11 – 13

Key.......................................................................................................................................................15

Examples of installation .................................................................................................................. 17, 18

Key.......................................................................................................................................................18

Tools.....................................................................................................................................................18

Examples of Installation

LRGT 16-1, LRGT 16-2, LRGT 17-1.......................................................................................................14

Key.......................................................................................................................................................15

Functional Elements

LRGT 16-1, LRGT 16-2, LRGT 17-1.......................................................................................................19

Connecting the conductivity transmitter..........................................................................................19, 20

Key.......................................................................................................................................................20

Safety power supply unit for LRGT 16-1, LRGT 16-2, LRGT 17-1...........................................................21

Tools ....................................................................................................................................................21

Wiring diagram for conductivity transmitter LRGT 16-1, LRGT 17-1 ......................................................21

Wiring diagram for conductivity transmitter LRGT 16-2.........................................................................22