Series 629HLP Differential Pressure Transmitters

Specications - Installation and Operating Instructions

Bulletin P-629HLP

The Series 629HLP Differential Pressure Transmitters are suitable for measuring

over-pressure, under-pressure, and differential pressure in compatible gases and

liquids with 1% accuracy. The 629HLP is suitable for all measuring tasks in commercial,

industrial or sanitary applications. Its single diaphragm design, allows it to measure

small increment pressure changes, and converts them to a linear analog output signal

from 4-20 mA or 0-10VDC.

Installation

Location/Mounting

The transmitter can be mounted in various locations as long it is not subject to

excessive vibration, shock, or extreme temperature (see Specications). The tubing

feeding the pressure port may be of any length, but longer lengths will increase the

response time slightly. Avoid sharp bends, and depending on the vibration and shock

it is recommended to install attenuating components.

To facilitate installation, mounting bracket A-629HLP-BKT, is available as accessory.

Position/Orientation

The transmitter is not sensitive to installation position. However, factory calibration

is performed with the unit in a vertical position and horizontal pressure connections.

Pressure Connections

Pressure connections are 1/4˝ female NPT or 1/4˝ female BSPT. Avoid excess sealant

and ensure the pressure passages are not blocked.

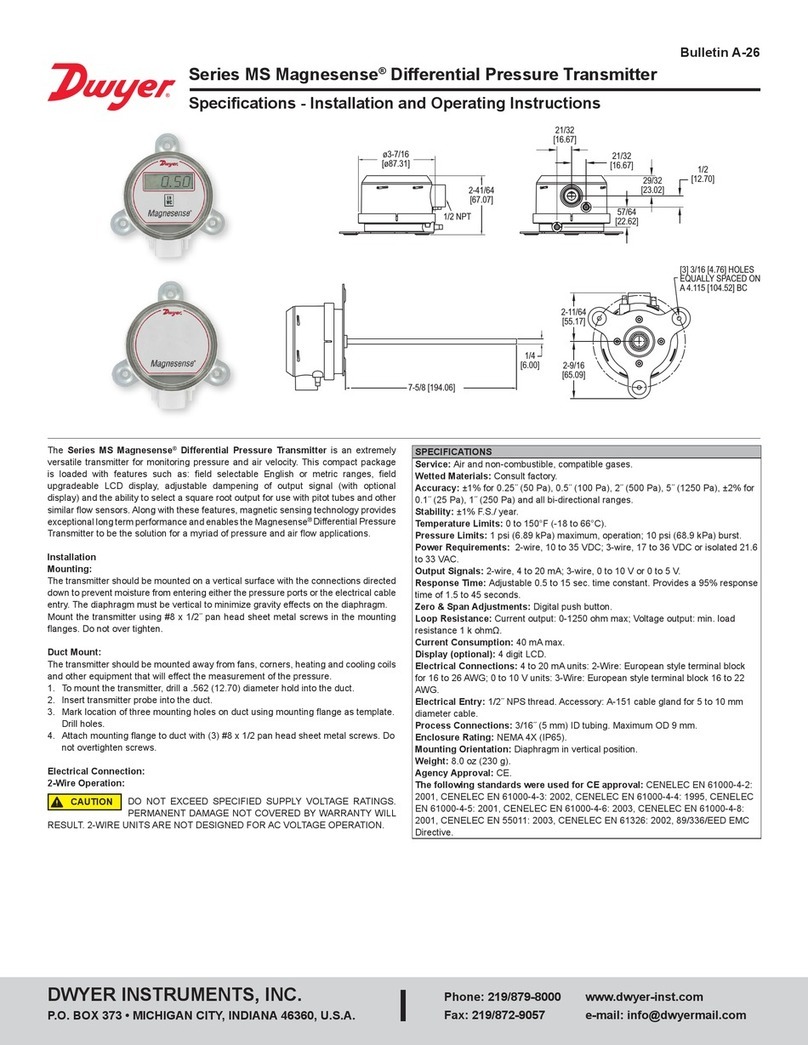

The piping should allow removal and reinstallation of the transmitter without shutdown

of the pressure system. Especially in applications where the differential pressures are

measured at high static line pressures that are above the overpressure limit of the

transmitter. It is recommended to install the 629HLP transmitter with a 3 way manifold

and a bypass valve (see Figure 1).

The manifold with the bypass valve will help to balance the pressure between the low

and high side of the transmitter.

Dwyer offers a 3-way Block manifold option for this purpose.

Close the drain valve and open the bypass valve. Then both shutoff valves are opened

to apply line pressure equally to both sides of the transducer. Finally, close the bypass

valve. To remove the transducer, open the bypass valve, close the shutoff valves and

open the drain valve.

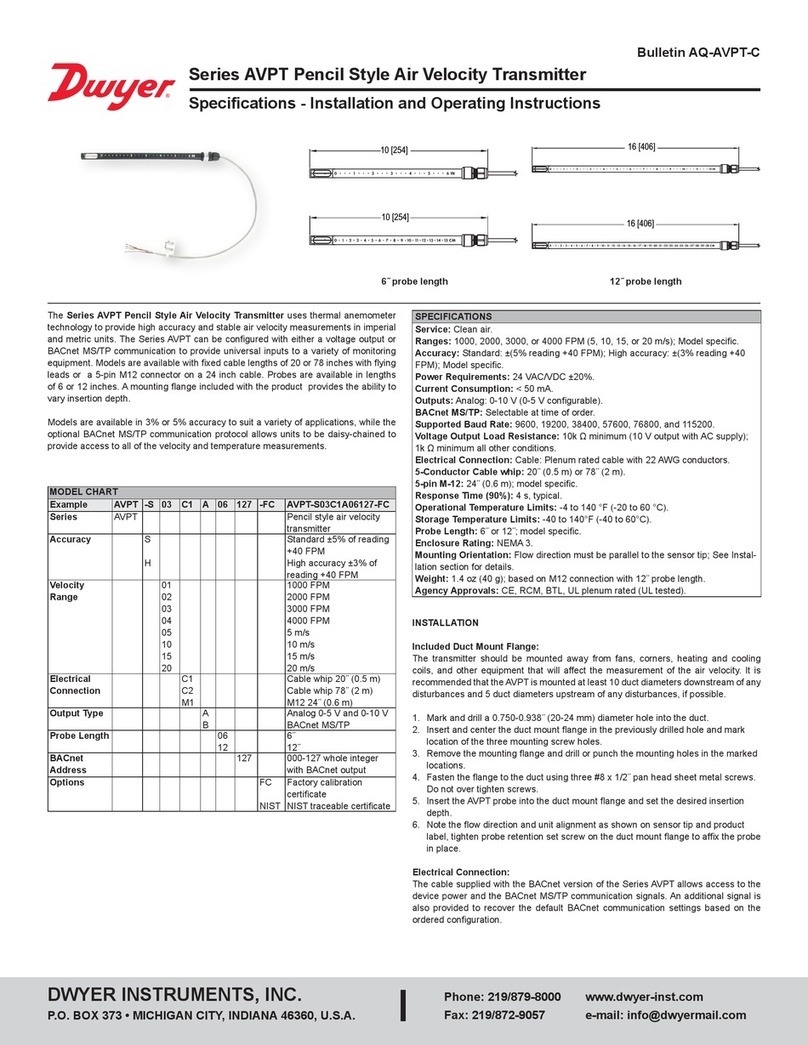

Figure 1

SPECIFICATIONS

Service: Compatible gases or liquids.

Wetted Material: 304 SS.

Housing Material: ABS.

Enclosure Rating: IP65.

Accuracy: ±1% from -5 to 60°C (23 to 140°F).

Stability: ±1% FS/year.

Temperature Limits: Ambient: -10 to 60°C (14 to 122°F); Process: -10 to 80°C (14

to 176°F).

Relative Humidity: 10% to 90% non-condensing.

Installation Position: Not position sensitive.

Pressure Limits: See Pressure Range Limits chart.

Burst Pressure: See Pressure Range Limits chart.

Static Pressure Limits: See Pressure Range Limits chart.

Output Signal: 4-20 mA, 0-10 VDC.

Response Time: 50 ms.

Rated Supply Voltage: 0-10 VDC Output: 12-36 VDC or 12-32 VAC (@ Max load

of 2k Ω) 4-20 mA output: 8-36 VDC.

Max Loop resistance: (Supply Voltage – 8 V) / 0.02 for 4-20 mA output.

Power Consumption: Vout = 13 mA max, Iout = 24 mA max.

Electrical Connections: Form A DIN 43650.

Process Connections: 1/4˝ female NPT, 1/4˝ female BSPT.

Weight: 1 lb 4 oz (567 g).

Approvals: CE, RCM.

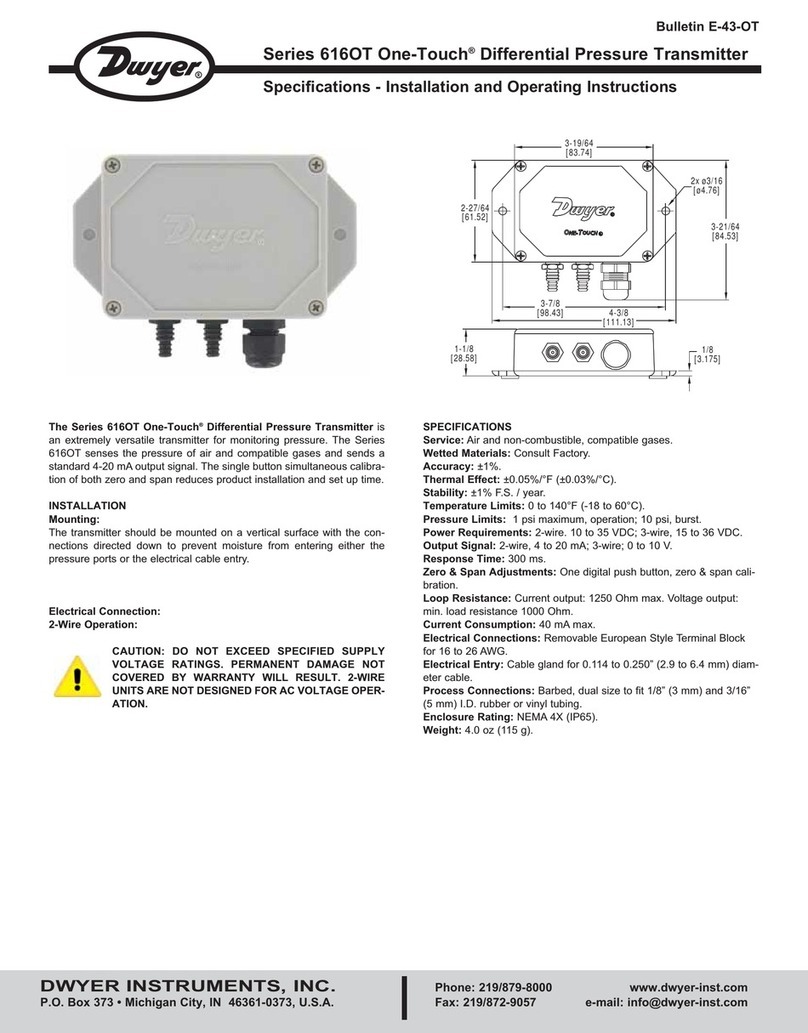

DIN CABLE

INLET

Ø.418 I.D.

3-1/4

[82.40]

2-3/16

[55.40]

2-7/16 [62.00]

1/4 NPT OR

1/4 BSPT

1-3/16

[30.00]

1-3/16

[30.00]

2-1/8

[53.81]

1-21/32

[42.00]

SHUTOFF VALVES DRAIN VALVE

PRESSURE MEASUREMENT SOURCE

SHUTOFF VALVES

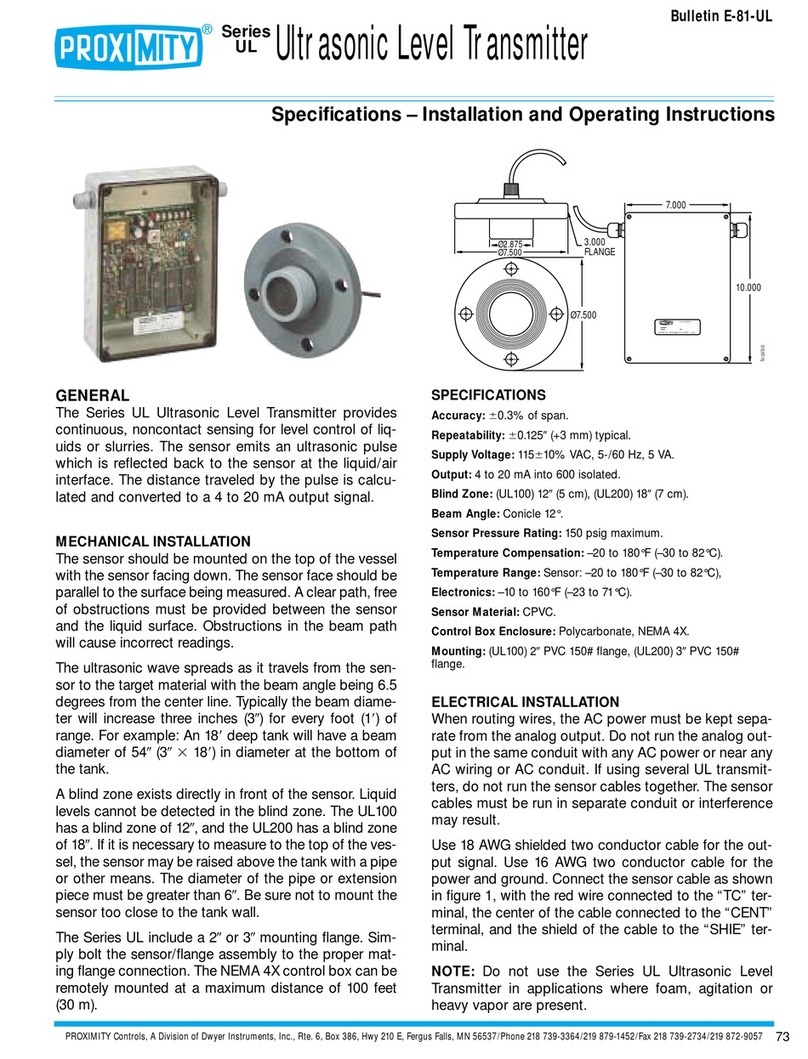

PRESSURE RANGE LIMITS

Pressure

Range

Maximum Static

Pressure

*Maximum Differential

Over Pressure

**Burst Differential

Pressure

0 to 1 bar

0 to 2.5 bar

0 to 4 bar

0 to 6 bar

0 to 15 psi

0 to 30 psi

0 to 60 psi

0 to 90 psi

25 bar

25 bar

25 bar

25 bar

360 psi

360 psi

360 psi

360 psi

5 bar

5 bar

12 bar

12 bar

70 psi

70 psi

174 psi

174 psi

8 bar

8 bar

18 bar

18 bar

115 psi

115 psi

260 psi

260 psi

Note: *The differential pressure limit, between high and low ports, that the

transmitter can withstand without affecting transmitter performance

**Differential pressures between high and low ports that exceed overpressure limits

will result in permanent diaphragm deformation, and any pressure higher than the

burst pressure limits will rupture the diaphragm.

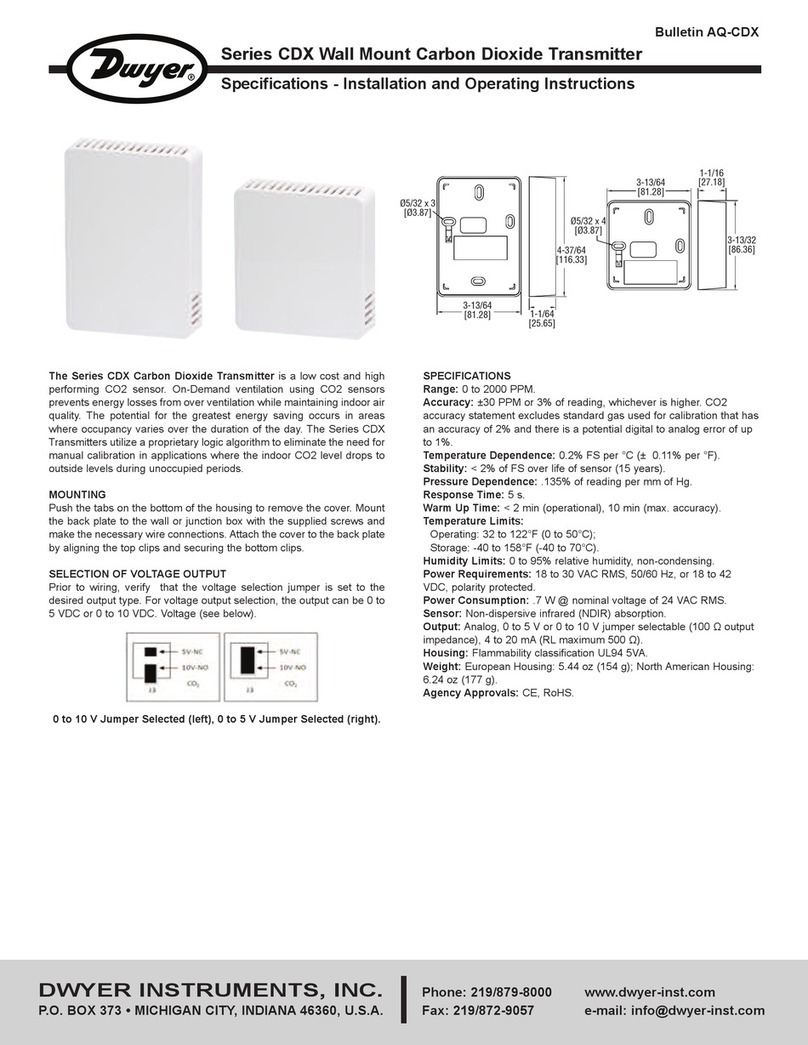

MODEL CHART

Example 629HLP -01 -P2 -S1 -FC 629HLP-01-P2-S1-FC

Series 629HLP Differential pressure transmitter

Range 01

02

04

06

15

30

60

90

0 to 1 bar

0 to 2.5 bar

0 to 4 bar

0 to 6 bar

0 to 15 psi

0 to 30 psi

0 to 60 psi

0 to 90 psi

Process

Connections

P2

P4

1/4˝ female NPT

1/4˝ female BSPT

Output Signal S1

S5

4-20 mA

0-10 VDC

Options FC

NIST

Factory calibration

NIST certicate

Note: PSI ranges available upon request. Contact factory for details.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219/879-8000

Fax: 219/872-9057

www.dwyer-inst.com