©Copyright 2009 Dwyer Instruments, Inc. Printed in U.S.A. 7/09 FR# 01-443277-00 Rev. 8

ELECTRICAL CONNECTIONS

ZERO

SPAN

13-30 VDC

(140 ma) +

-RECEIVER

mA

LED DISPLAY

POSITIVE SUPPLY

TERM

1 (+)

TERM 2 (-)

TERM 4 (+)

OPTIONAL LED DISPLAY

YELLOW LED DISPLAY

CONNECTOR

PRESS AND

HOLD TO

ZERO THE

DISPLAY

PRESS TO DISPLAY

THE GAGE’S

PRESSURE RANGE

BE SURE TO TURN OFF POWER WHEN

CONNECTING OR REMOVING THE

DISPLAY’SCONNECTOR. FAILURE TO DO

SO CAN RESULT IN THE GAGE DAMAGE.

TRANSMITTER CONNECTION:

- TURN OFF POWER

- CONNECT THE POWER

SUPPLY AND RECEIVER TO

TERM 1 AND TERM 2 OF THE

GAGE ASSHOWN

- CONNECT POWER SUPPLY

(+) TO TERMINAL 4 (REQUIRED

FOR THE OPTIONAL DISPLAY ONLY)

- INSTALL THE DISPLAY’SCONNECTOR

- TURN ON POWER

POWER

SUPPLY

Fig. D: Current output with optional LED display

ZERO

SPAN

PRESS AND

HOLD TO

ZERO THE

DISPLAY

PRESS TO

DISPLAY THE

GAGE’S

PRESSURE

RANGE

OPTIONAL LED DISPLAY

13-30 VDC

(40 ma)

13-30 VDC

(100 ma)

POWER

SUPPLY

LED SUPPLY

POWER SUPPLY

+

+

-

-

TRANSMITTER CONNECTION:

- TURN OFF POWER

- CONNECT THE POWER SUPPLY

AND RECEIVER TO TERM 1 AND

TERM 2 OF THE GAGE ASSHOWN

OPTIONAL DISPLAY CONNECTION:

- CONNECT LED POWER SUPPLY

(-) TO TERMINAL 3

- CONNECT LED POWER SUPPLY

(+) TO TERMINAL 4

- INSTALL THE DISPLAY’SCONNECTOR

- TURN ON POWER

LED DISPLAY

CONNECTOR

YELLOW

BE SURE TO TURN OFF POWER WHEN

CONNECTING OR REMOVING THE

DISPLAY’SCONNECTOR. FAILURE TO DO

SO CAN RESULT IN THE GAGE DAMAGE.

TERM

1 (+)

TERM 4 (+)

TERM 3 (-)

TERM 2 (-)

RECEIVER

mA

LED DISPLAY

NEGATIVE SUPPLY

LED DISPLAY

POSITIVE SUPPLY

Fig. E: Current output with optional LED display using two power supplies

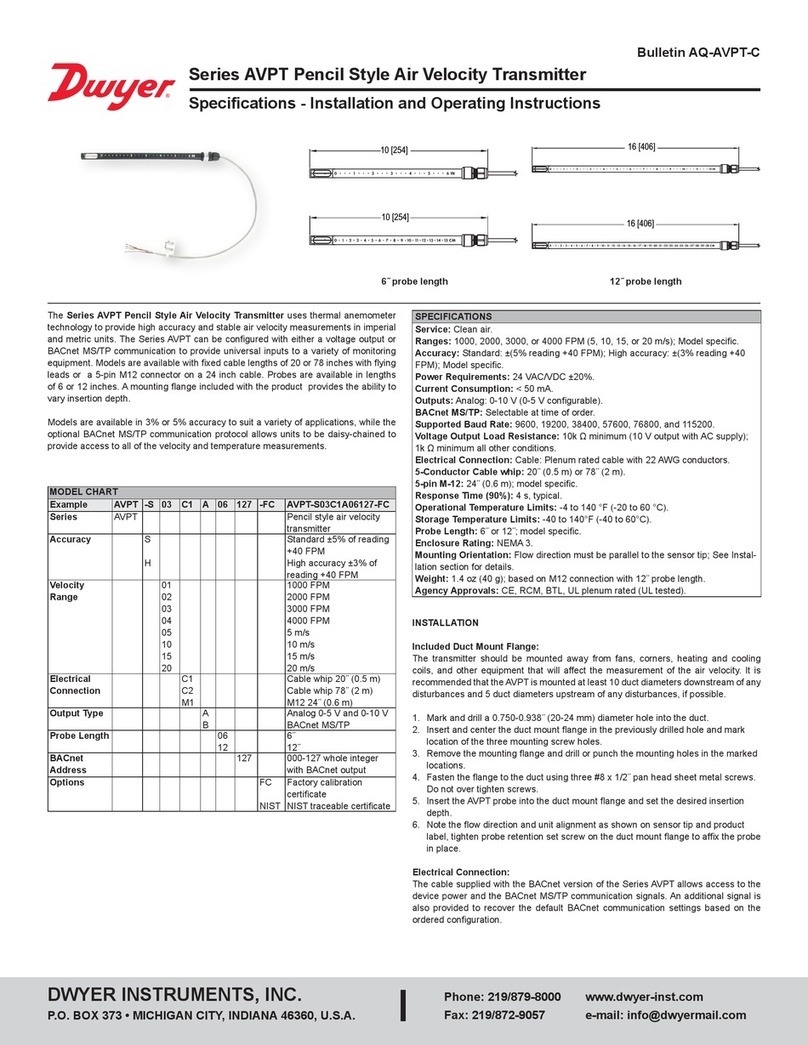

Wire Length - The maximum length of wire connecting transmitter and receiver is a

function of wire size and receiver resistance. Wiring should not contribute to more

than 10% of receiver resistance to total loop resistance. For extremely long runs (over

1000 ft.), choose receivers with higher resistance to minimize size and cost of con-

necting leads. When the wiring length is under 100 feet, lead wire as small as 22 AWG

can be used.

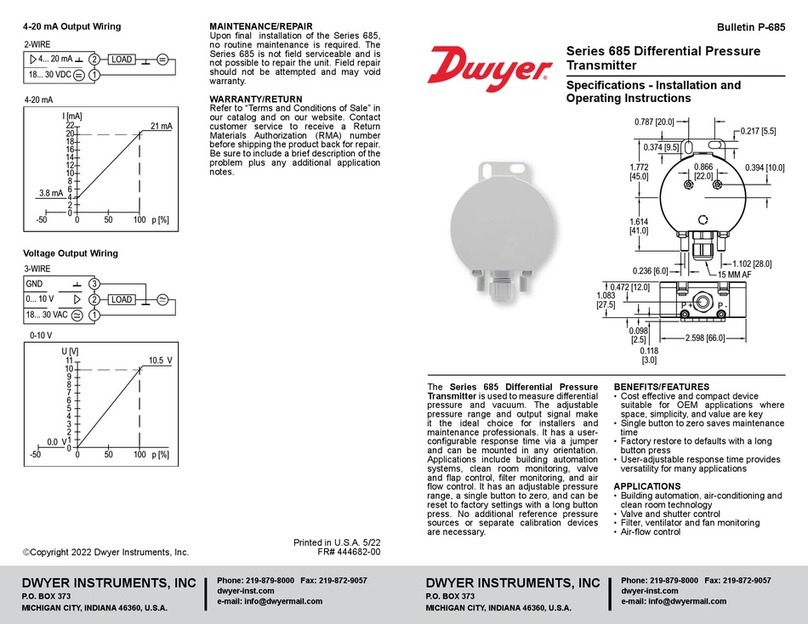

Current (4-20 mA) Output Operation - An external power supply delivering 13-30

VDC with minimum current capability of 40 mA DC (per transmitter)is required to

power the control loop. See Fig. C for connection of the power supply, transmitter,

and receiver. The range of the appropriate receiver load resistance (RL) for the DC

power supply voltage available is expressed by the formula:

RLMax = Vps – 13

20 mA DC

Shielded cable is recommended for control loop wiring.

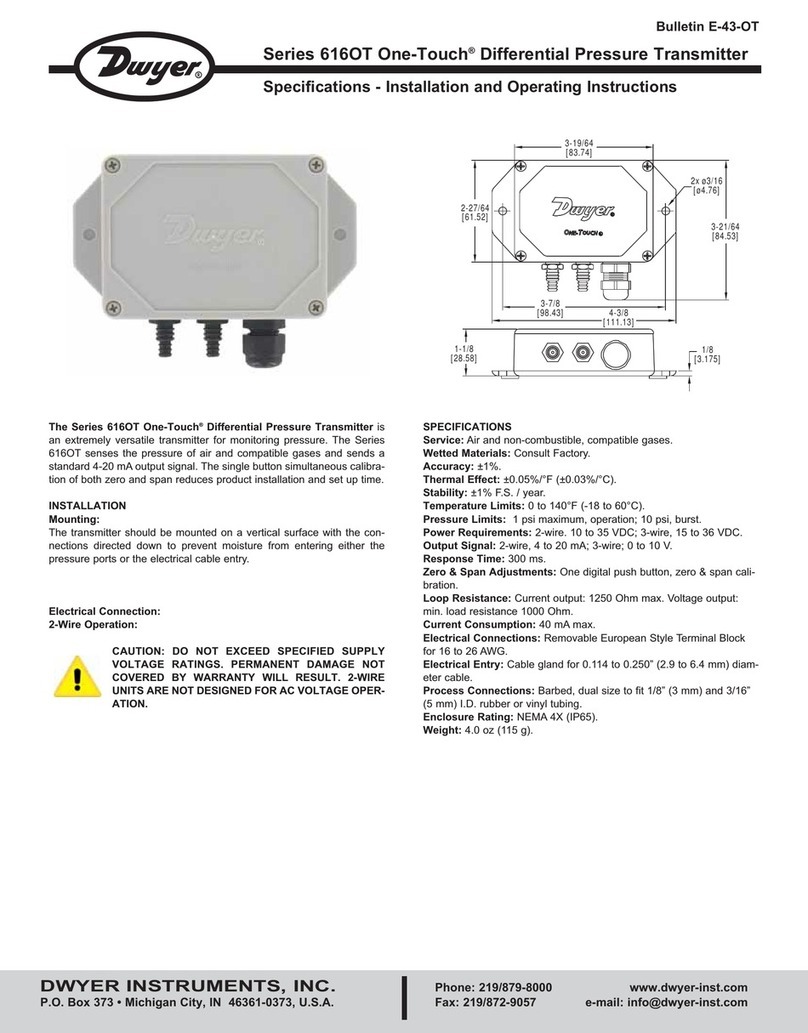

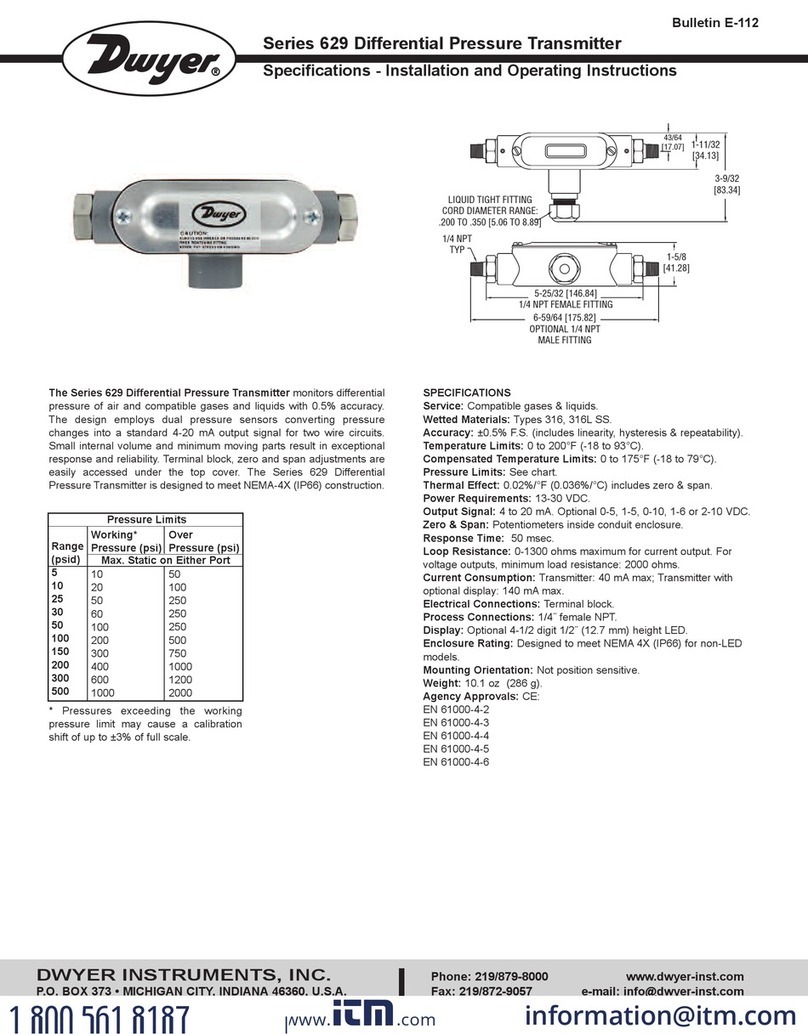

Electrical connections to the Series 629 pressure transmitters are made to the termi-

nal block located inside the housing. Remove the screws and lift off the cover. Wire

as shown in Fig. C, D or E. Use Fig. C for current output connection. Use Fig. D for

current output with optional LED display. Use Fig. E for current output with optional

LED display using two power supplies. If ordering pre-wired cable, black wire is neg-

ative (-) and red wire is positive (+).

Fig. C: Current output connection

Voltage Output

Fig. F: Voltage output connection

PRESSURE

TRANSMITTER

1 RED

2 BLACK (COMMON)

3 WHITE (+V OUT)

4 (NC)

RECEIVER +V in

POWER

SUPPLY

13-30 VDC

ZERO PRESS AND

HOLD TO

ZERO THE

DISPLAY

PRESS TO

DISPLAY THE

GAGE’S

PRESSURE

RANGE

LED DISPLAY

CONNECTOR

YELLOW

OPTIONAL LED DISPLAY

BE SURE TO TURN OFF POWER WHEN

CONNECTING OR REMOVING THE

DISPLAY’SCONNECTOR. FAILURE TO DO

SO CAN RESULT IN THE GAGE DAMAGE.

VOLTAGE OUTPUT

TRANSMITTER CONNECTION:

- TURN OFF POWER

- CONNECT POWER SUPPLY

(+) TO TERMINAL 1

- CONNECT POWER SUPPLY

(-) TO TERMINAL 2 AND

THE RECEIVER (-)

- CONNECT THE RECEIVER

(+) TO TERMINAL 3

- CONNECT LED POWER SUPPLY

(+) TO TERMINAL 4

- INSTALL THE DISPLAY’SCONNECTOR

- TURN ON POWER

POWER

SUPPLY

13-30 VDC

(140 ma)

RECEIVER

+

-

-

+V OUT

LED DISPLAY

POSITIVE SUPPLY

TERM 4 (+) TERM 1 (+)

TERM 2 (-)

TERM 3 (-)

SPAN

Fig. G: Voltage output with optional LED display

VOLTAGE (0-5, 1-5, 0-10, 1-6 or 2-10 Volt) OUTPUT OPERATION

For voltage outputs, wire as shown in Fig. F or Fig. G. Use Fig. F for voltage output

connection. Use Fig. G for voltage output with optional LED display. Terminal 1 is pos-

itive (+), terminal 2 is negative (-), terminal 3 is +Vout, terminal 4 is LED positive sup-

ply. If ordering optional pre-wired cable, black wire is negative (-), red wire is positive

(+) and white wire is +Vout.

MULTIPLE RECEIVER INSTALLATION

An advantage of the standard 4-20 mA DC output signal provided by the Series 629

Differential Transmitter is that any number or receivers can be connected in series in

the current loop. Thus, an A-701 digital readout, an analog panel meter, a chart

recorder, process controlling equipment, or any combination of these devices can be

operated simultaneously. It is necessary only that each be equipped with a standard

4-20 mA input and proper polarity of the input connections be observed when insert-

ing the device into the current loop. If any of the receiving devices displays a negative

or downscale reading this indicates that the signal input leads are reversed.

MAINTENANCE

Upon final installation of the Series 629 Differential Pressure Transmitter and the com-

panion receiver, no routine maintenance is required. A periodic check of the system

calibration is recommended. The Series 629 Differential Pressure Transmitter is not

field serviceable and should be returned if repair is needed (field repair should not be

attempted and may void warranty). Be sure to include a brief description of the prob-

lem plus any relevant application notes. Contact customer service to receive a return

goods authorization number before shipping.

Current Output

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000 www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, U.S.A. Fax: 219/872-9057 e-mail: info@dwyer-inst.com

E-112:LED 626/628 7/22/09 2:34 PM Page 2