Model 485 Dispensing Systems User Guide

Contents

Safety................................................................................................................... 3

Using Safe Operating Pressures..................................................................................3

Operating Specifications.......................................................................................3

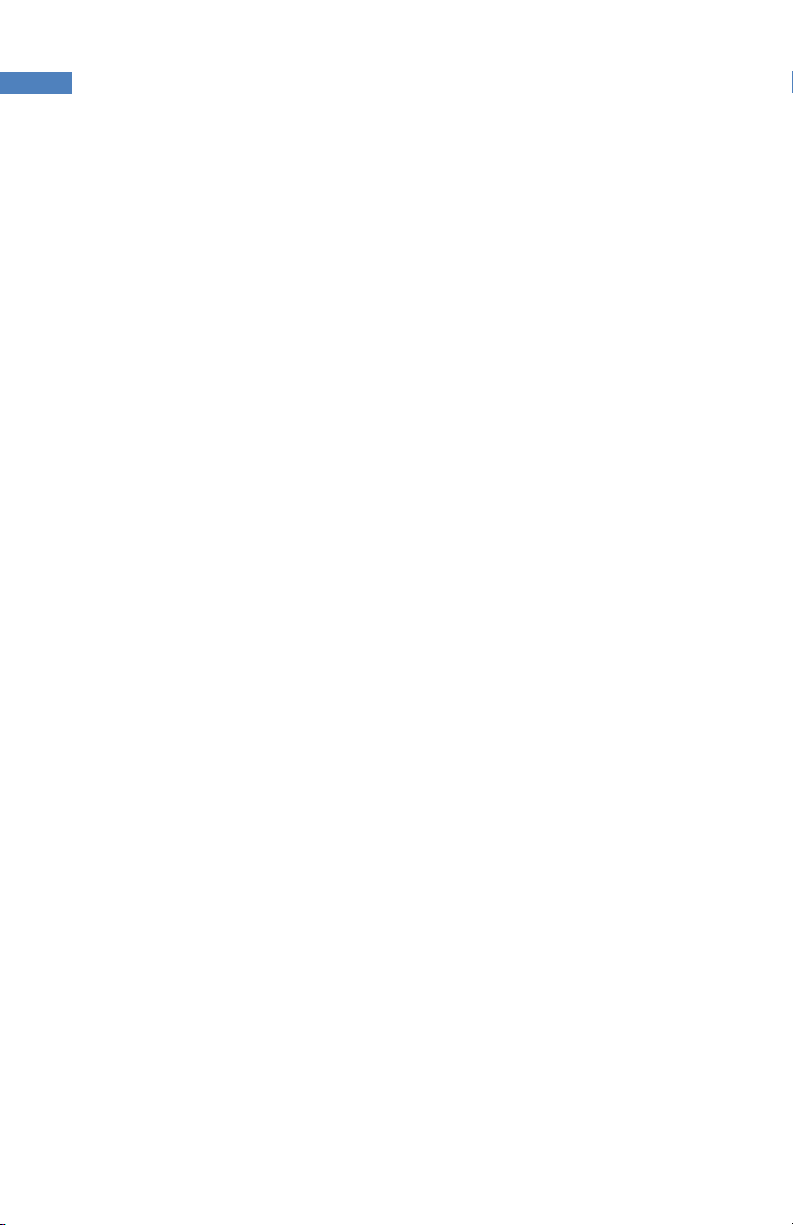

Configuration Overview ....................................................................................... 4

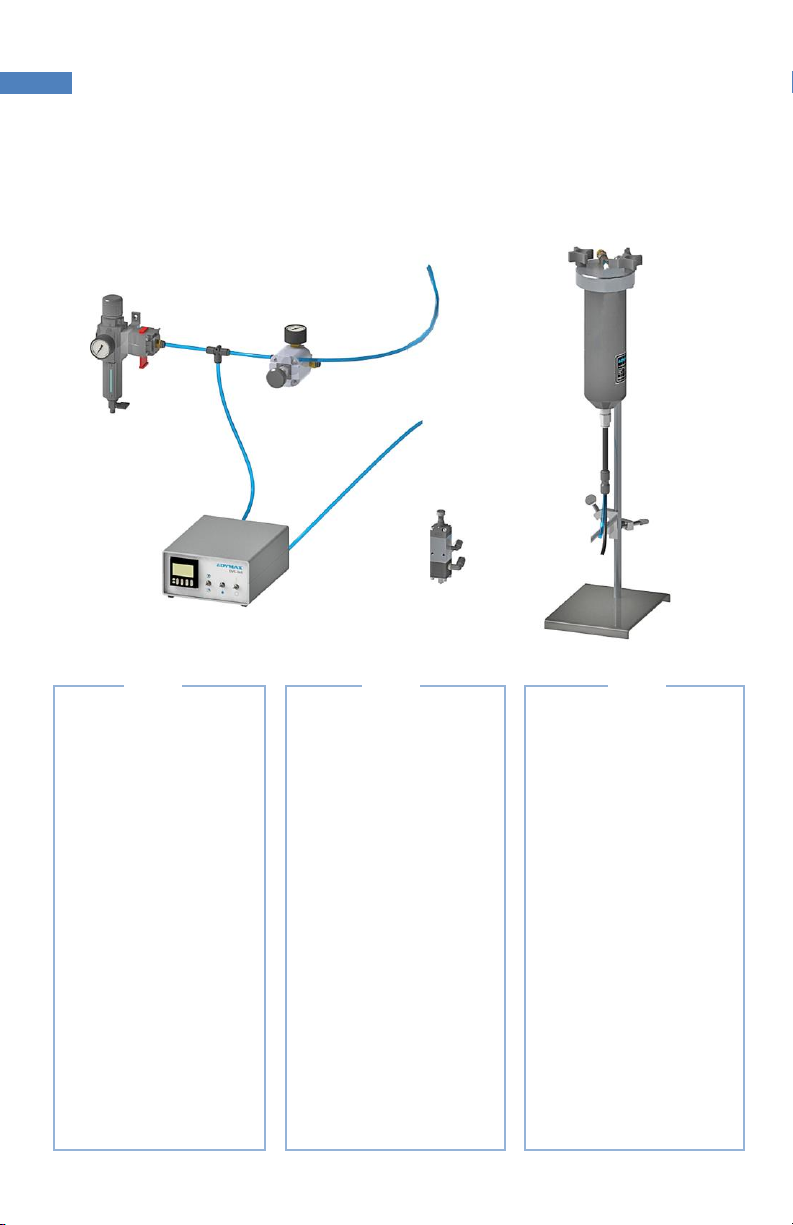

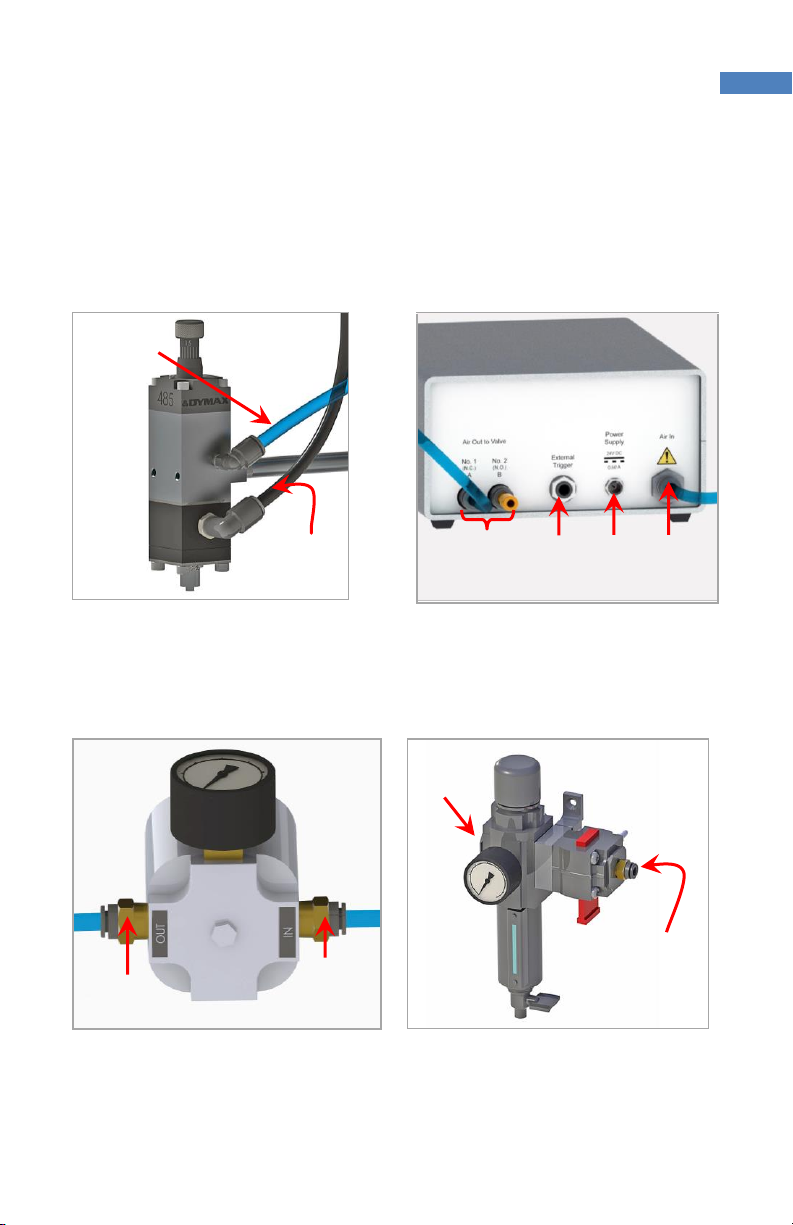

Key System Connections....................................................................................... 5

Dispensing Tips .................................................................................................... 6

System Configurations.......................................................................................... 7

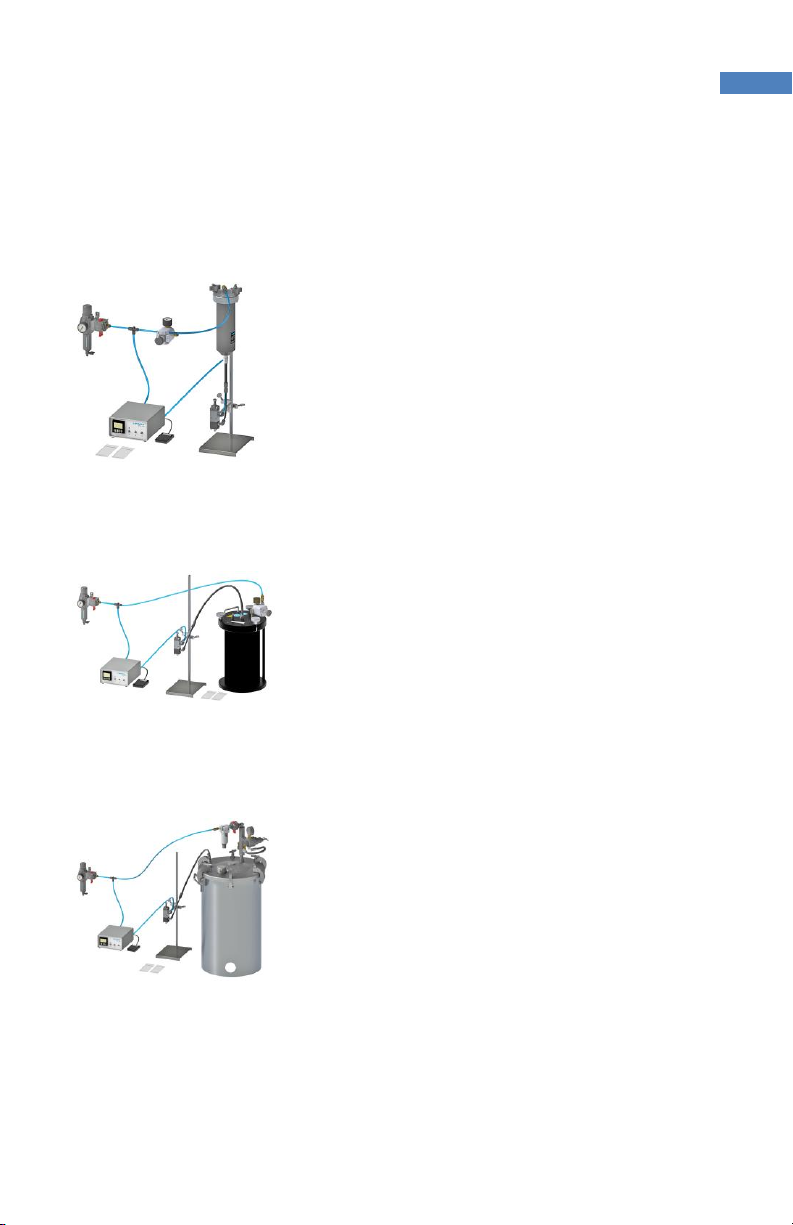

A - Systems Using a Cartridge Retainer ......................................................................8

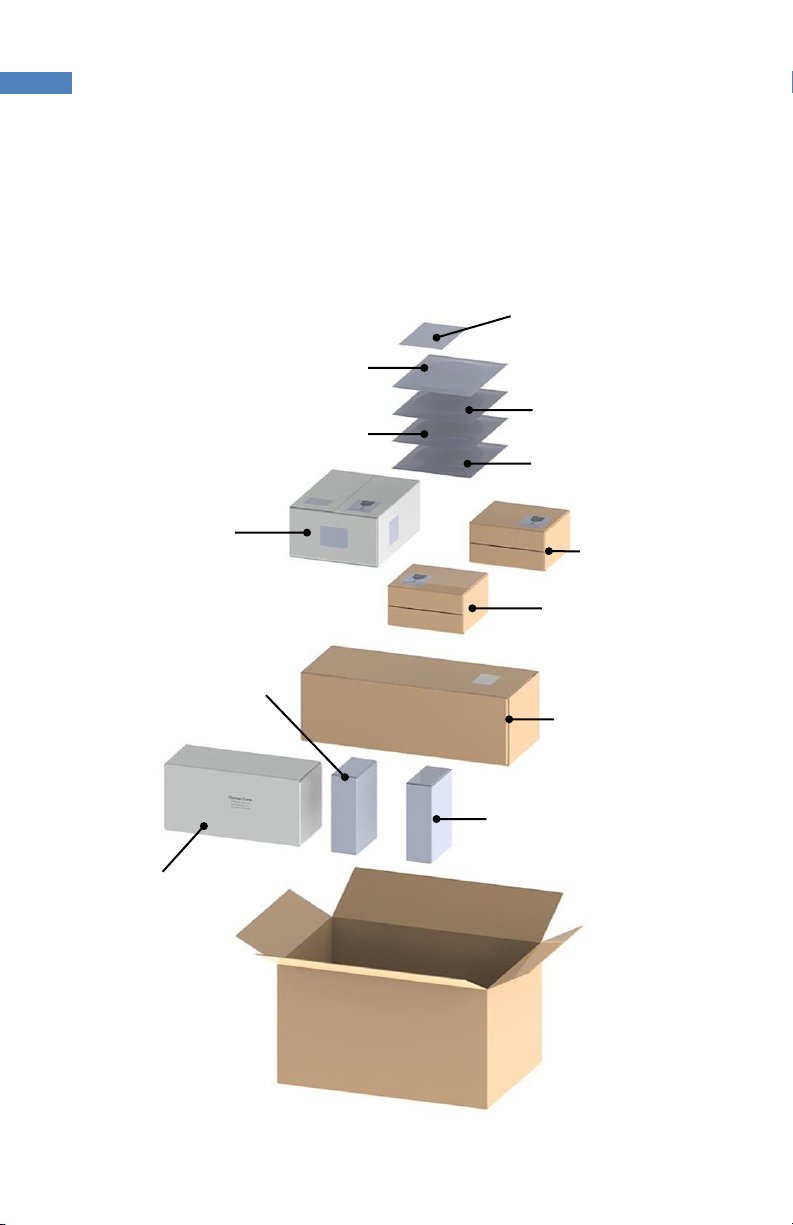

Packaged Components .........................................................................................8

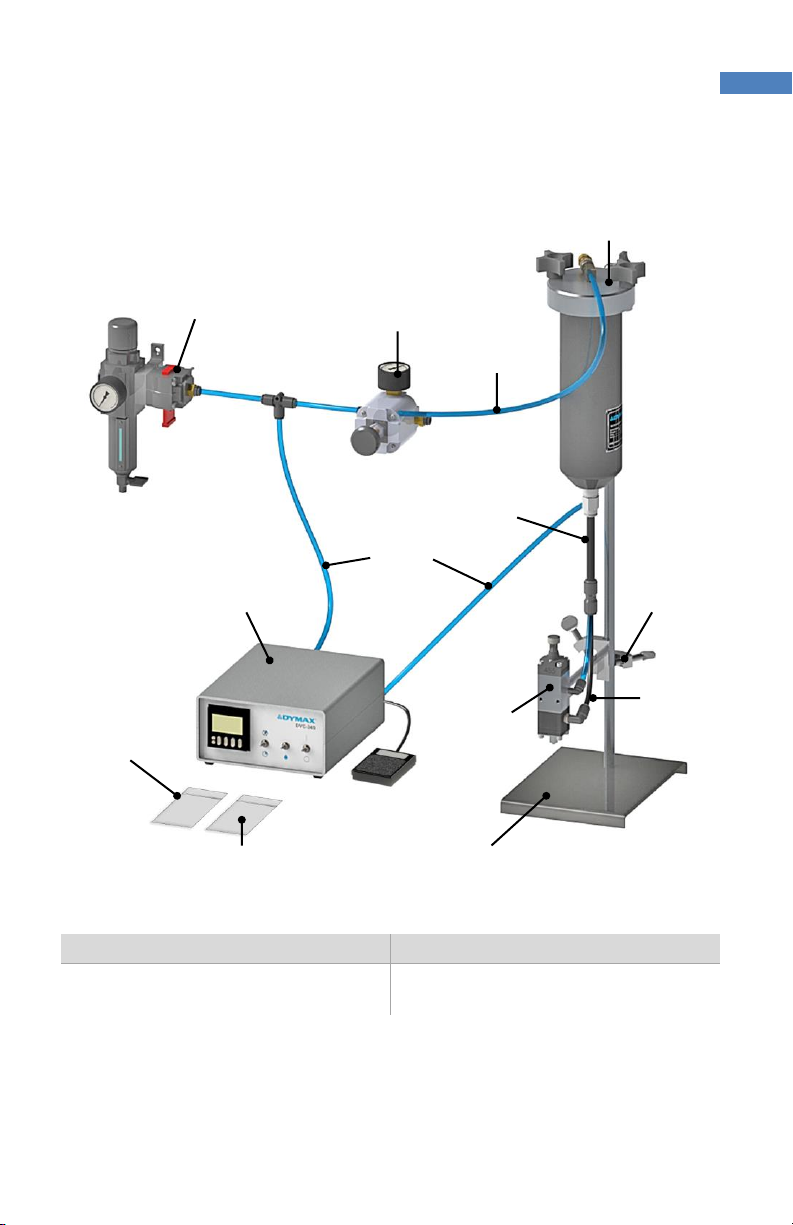

Assembled System................................................................................................9

B - Systems Using a Bottle Drop-In Tank...................................................................10

Packaged Components .......................................................................................10

Assembled System..............................................................................................11

Installing the Fluid Line to the Reservoir ............................................................12

C - Systems Using a 10-Gallon Pressure Tank ...........................................................13

Packaged Components .......................................................................................13

Assembled System..............................................................................................14

Installing the Fluid Line to the Reservoir ............................................................15