Contents

Introduction.................................................................. 4

Intended Audience.................................................................... 4

Where to Get Help .................................................................... 4

Safety............................................................................ 5

General Safety Considerations................................................ 5

Specific Safety Considerations................................................ 5

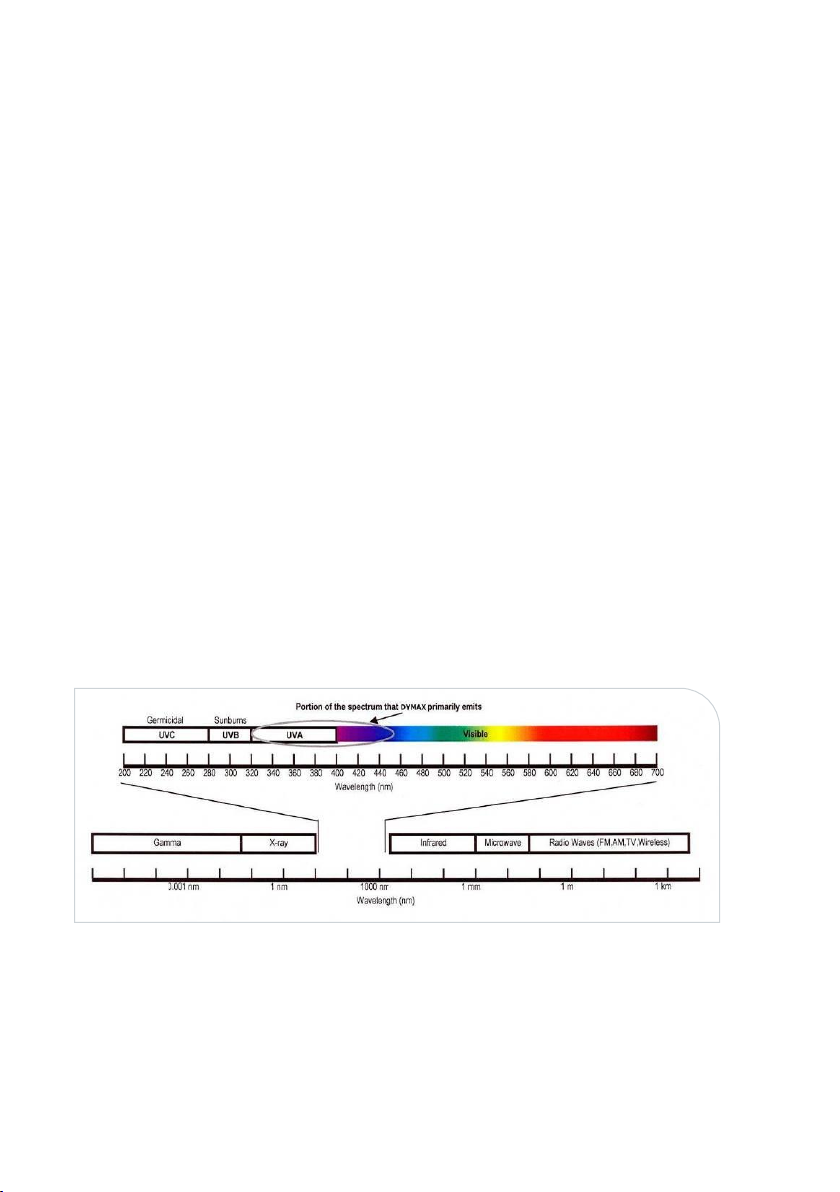

Dymax UV Light-Curing System Safety Considerations ...... 6

Product Overview ........................................................ 9

Description of the BlueWave QX4 V2.0.................................. 9

Features & Benefits................................................................... 10

Validation.................................................................................... 11

Front LCD Panel........................................................................ 12

Back Panel ................................................................................. 13

Unpacking..................................................................... 14

Parts Included............................................................................ 15

System Setup ............................................................... 16

System Connections................................................................. 16

LED Heads & Lenses................................................................ 17

Operation...................................................................... 18

ADMIN Mode ............................................................................. 19

PRODUCTION Mode ................................................................ 21

PLC Operation........................................................................... 22

System Settings ........................................................... 31

System Information...................................................... 34

Cleaning & Maintenance.............................................. 35

LED Head Optic Lens ............................................................... 35

Alarm Messages........................................................... 36

Troubleshooting........................................................... 38

Spare Parts and Accessories ...................................... 39

Specifications............................................................... 41

Warranty ....................................................................... 43