Dyna-Flo Control Valve Services Ltd.

Phone: 780 •469 •4000 Toll Free: 1 •866 •396 •2356 Fax: 780 •469 •4035 Website: www.dynaflo.com

Model DFR 070/156/220 Rotary Actuator

P-DFR3M0919A 8

Operation, Parts, and Instruction Manual

ACTUATOR ADJUSTMENT

Before You Begin:

• Read the General and Scope section of this manual (Page 2).

• Read Safety Caution (Page 2).

• Use safe work practices and lock out procedures.

• Disconnect supply lines (air or gas), electric power, or control

signal to the actuator. Sudden movement of actuator can

cause damage or injury, make sure actuator will not operate.

• Vent any pneumatic actuator loading pressure.

• Relieve process pressure and drain the process fluid from up

and down stream of valve.

ACTUATOR MOUNTING (Continued)

15 Check the position of the valve ball or disk and note the

direction of rotation for valve operation.

For actuators without a handwheel:

ARe-install the cover plate assembly (Keys 36, 37,

38, 39, 40, 41, 42, and 43). Position the cover plate

assembly so that the travel indicator (Key 42) will

rotate according to the position of the valve ball/disk

and direction of valve operation as determined

above.

BApply anti-seize compound (Key A) to the threads of

the cap screws (Key 45) and secure the cover plate

(Key 36) in place using the washers (Key 44) and

cap screws. Torque the cap screws to the

recommend torque value listed in Table 4.

Note: If the holes of the actuator housing (Key 6)

and the cover plate (Key 36) are out of alignment, it

may be necessary to loosen the mounting yoke cap

screws (Key 7) and reposition the actuator housing.

DO NOT stroke the actuator while the cover plate is

removed.

For actuators with a manual handwheel:

ARefer to the Top Mounted Handwheel section of this

manual (Page 25).

16 Refer to the Actuator Adjustment section for instructions

on re-adjusting the turnbuckle assembly.

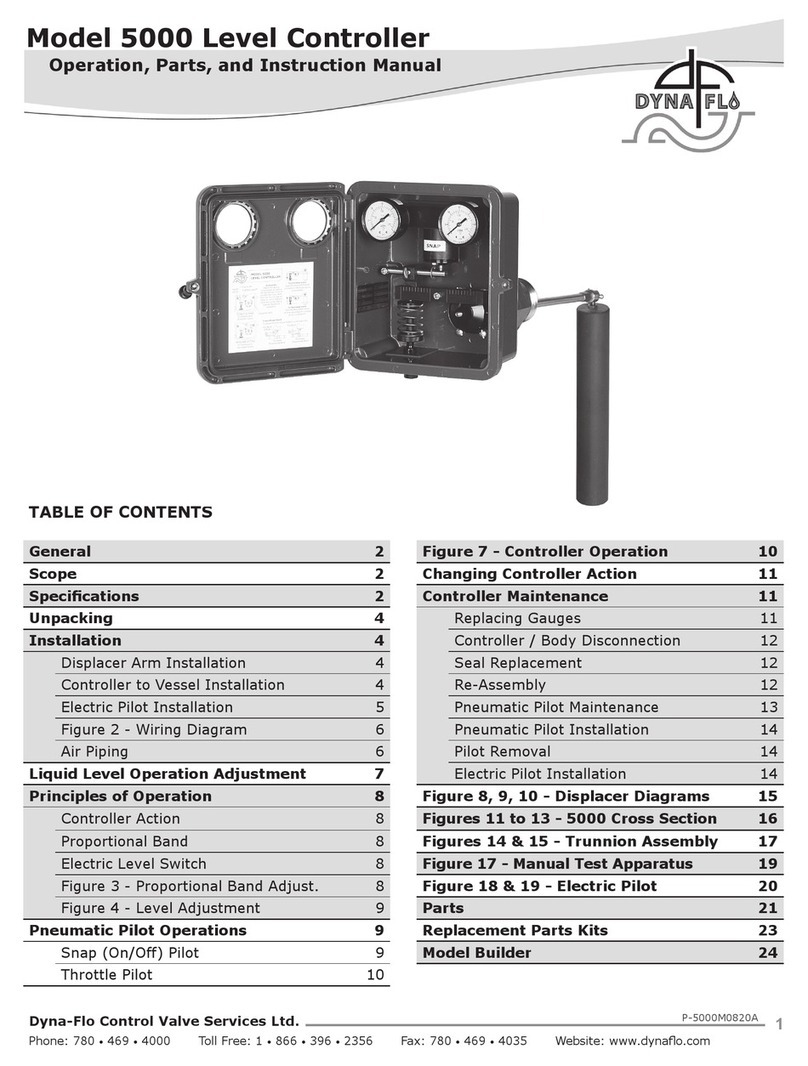

Figure 7 Lever Operating Clearance

• Be aware of potentially hazardous process material that may

be present in-line and in-valve. Isolate the valve from

process pressure. Use a bypass or block valve if necessary,

or completely shut off the process. Relieve internal valve

pressure (refer to the appropriate valve instruction manual).

Special Tools Required:

• Regulated air supply (to stroke the actuator).

• Wrenches (See Table 5 for open-end wrenches required for

turnbuckle adjustment).

Note: When the turnbuckle (Key 29) is properly adjusted,

the valve will be completely closed or open when the actuator

is against its travel stops (Keys 17 & 18). For accurate zero-

degree valve ball or disk position adjustment, the control valve

must be removed from the pipeline and the actuator may also

need to be removed from the valve (Refer to the appropriate

valve instruction manual).

OPERATING CLEARANCE

SIZE 070 TO 220 = 1/16” (1.6 mm)

SIZE 070 TO 220 = 1-3/8” (34.9 mm)