Dyna-Flo Control Valve Services Ltd.

Phone: 780 •469 •4000 Toll Free: 1 •866 •396 •2356 Fax: 780 •469 •4035 Website: www.dynaflo.com

Model DFR 026 Rotary Actuator

P-DFR1M0918A 8

Operation, Parts, and Instruction Manual

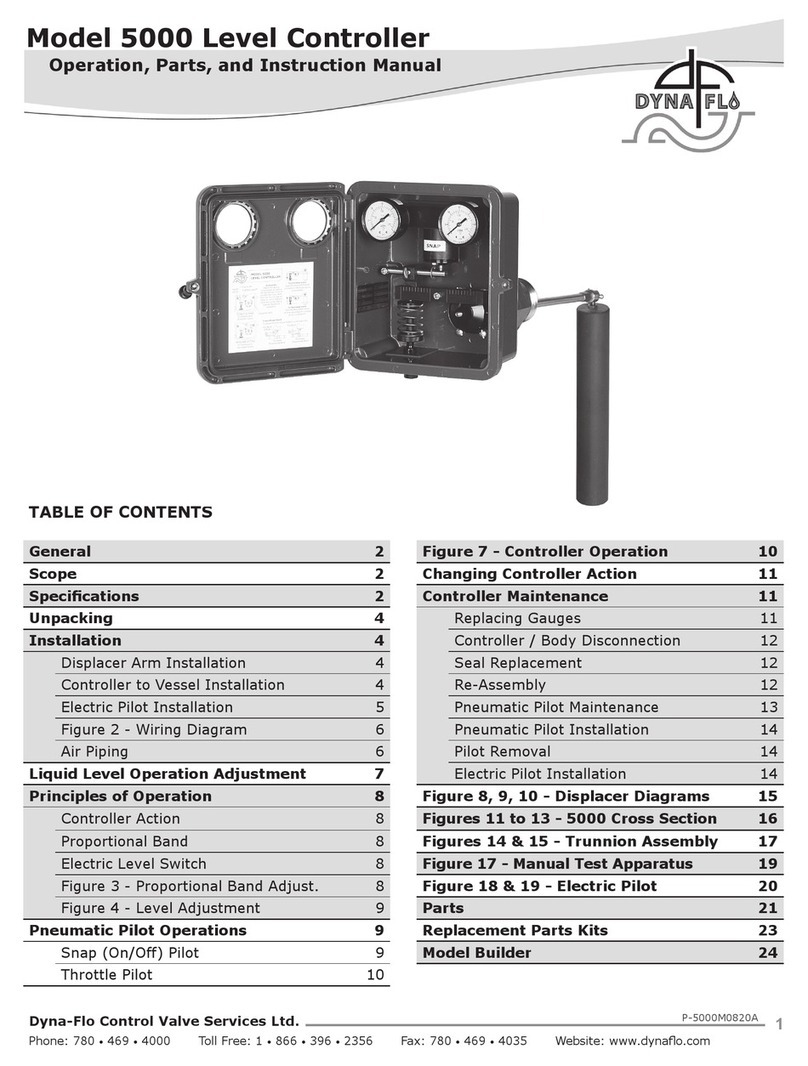

Figure 8 Spring Adjustment

SPRING ADJUSTMENT (Continued)

INITIAL SET (Continued)

1When performing spring adjustment on the DFR 026, it will

be necessary to have a valve shaft (Key V) inserted into

the actuator and to approximately pre-adjust the up travel

stop to its desired position. Note: Travel error will occur if

this step is not followed.

2Disconnect any instrumentation attached to the actuator.

3Remove the screws (Key 28) and the access plate (Key 27).

4Apply operating pressure to the diaphragm casing, when

the spring is properly adjusted, the diaphragm rod (Key

16) will start to move when the Initial Set pressure

(indicated on the nameplate (Key 33) or in Table 5) is

reached. Make note whether the diaphragm rod started to

move before or after the Initial Set value.

5Relieve actuator casing pressure.

6Using a flat-head screwdriver or a flat-bladed tool,

adjust the spring adjuster (Key 12) accordingly:

• To increase Initial Setting (increase spring compression)

– Turn the spring adjuster to the left (clockwise when

viewed from above).

• To decrease Initial Setting (decrease spring compression)

– Turn the spring adjuster to the right (counter-

clockwise when viewed from above).

7Repeat Steps 4 – 6 until the Initial Set pressure is reached.

8Re-install the access plate (Key 27) and screws (Key 28).

9Check the position of the travel indicator (Key 6), adjust if

necessary.

STROKE RANGE

Should the desired stroking range be unachievable during

normal operating conditions with the casing pressure used,

it may be possible to adjust the stroking range by making a

spring adjustment. A spring adjustment will shift the casing

pressure span and either increase or decrease the casing

pressure at which the actuator begins its stroke, this will

affect the pressure at which the actuator reaches full travel.

Refer to the Initial Set section and adjust the spring adjuster

(Key 12) as follows:

To shift the casing pressure span downward – rotate the

spring adjuster to the right (counter-clockwise when viewed

from above).

To shift the casing pressure span upward – rotate the

spring adjuster to the left (clockwise when viewed from above).

CHANGING ACTUATOR STYLE

Refer to the Before You Begin section of the Actuator Mounting

instructions (Page 5).

Mounting Styles A and D

Style A is right-hand mounted and Style D is left-hand

mounted, in all other ways Styles A and Dare identical.

Refer to Figure 10.

Mounting Styles B and C

Style B is right-hand mounted and Style C is left-hand

mounted, in all other ways Styles B and Care identical.

Refer to Figure 10.

Note: To convert a Style A or Dinto a Style B or Cactuator,

the actuator must first be separated from the control valve.

Refer to Steps 1-4 of the Disassembly Section and 1-2 of Valve

Removal Section (Page 11).

Refer to Figure 9.

1Remove the machine screws (Key 10) and travel scale/hub

assembly (Keys 5, 6, 7, 8, & 9).

2Remove the cap screws (Key 4) and mounting yoke (Key

3).

TURNING THE SPRING

ADJUSTER (KEY 12)

COUNTER-CLOCKWISE

(TO THE RIGHT) WILL

DECREASE THE INITIAL

SETTING.

TURNING THE SPRING

ADJUSTER (KEY 12)

CLOCKWISE (TO THE

LEFT) WILL INCREASE

THE INITIAL SETTING.