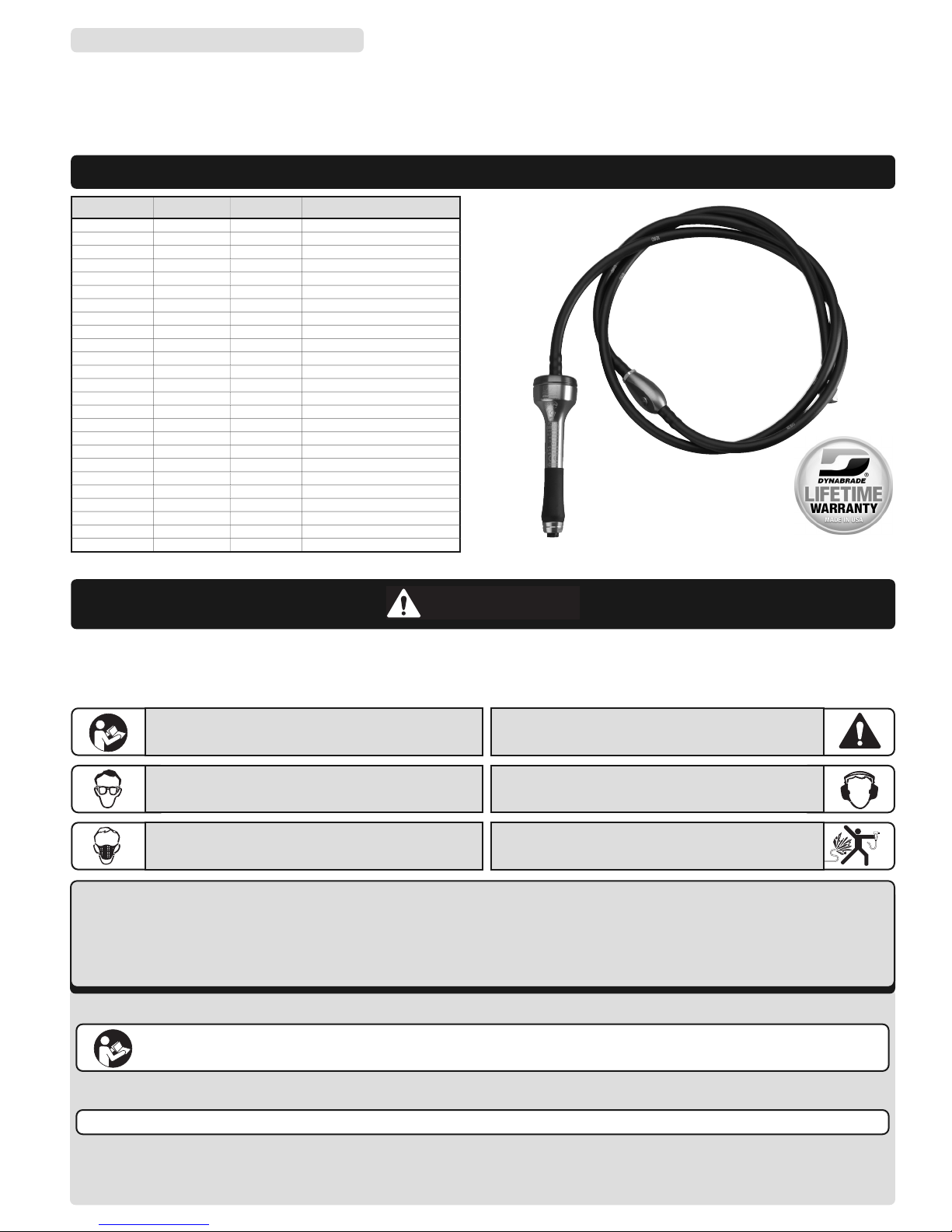

Model Number RPM hp (Watt) Sound dB(A) Air Consumption Collet Size Weight Length Height

51622 35,000 .1 (75) 74 8 SCFM (227 LPM) 1/8" 1.1 (.5) 5-1/4 (132) 1-7/8 (49)

51623 35,000 .1 (75) 76 8 SCFM (227 LPM) 1/8" 1.2 (.5) 6 (152) 1-7/8 (49)

51624 35,000 .1 (75) 74 8 SCFM (227 LPM) 3 mm 1.1 (.5) 5-1/4 (132) 1-7/8 (49)

51629 50,000 .1 (75) 76 8 SCFM (227 LPM) 1/8" 1.1 (.5) 5-1/4 (132) 1-7/8 (49)

51630 50,000 .1 (75) 73 8 SCFM (227 LPM) 1/8" 1.2 (.5) 6 (152) 1-7/8 (49)

51631 50,000 .1 (75) 76 8 SCFM (227 LPM) 3 mm 1.1 (.5) 5-1/4 (132) 1-7/8 (49)

51632 60,000 .1 (75) 72 8 SCFM (227 LPM) 1/8" 1.1 (.5) 5-1/4 (132) 1-7/8 (49)

51633 60,000 .1 (75) 72 8 SCFM (227 LPM) 1/8" 1.2 (.5) 6 (152) 1-7/8 (49)

51634 60,000 .1 (75) 72 8 SCFM (227 LPM) 3 mm 1.1 (.5) 5-1/4 (132) 1-7/8 (49)

51700 60,000 .1 (75) 69 8 SCFM (227 LPM) 1/8" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51701 60,000 .1 (75) 69 8 SCFM (227 LPM) 3 mm .8 (.4) 5-1/4 (132) 1-1/2 (37)

51702 60,000 .1 (75) 69 8 SCFM (227 LPM) 3/32" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51703 50,000 .1 (75) 64 8 SCFM (227 LPM) 1/8" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51704 50,000 .1 (75) 64 8 SCFM (227 LPM) 3 mm .8 (.4) 5-1/4 (132) 1-1/2 (37)

51705 50,000 .1 (75) 64 8 SCFM (227 LPM) 3/32" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51706 35,000 .1 (75) 65 8 SCFM (227 LPM) 1/8" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51707 35,000 .1 (75) 65 8 SCFM (227 LPM) 3 mm .8 (.4) 5-1/4 (132) 1-1/2 (37)

51708 35,000 .1 (75) 65 8 SCFM (227 LPM) 3/32" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51730 50,000 .1 (75) 69 8 SCFM (227 LPM) 1/8" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51731 60,000 .1 (75) 69 8 SCFM (227 LPM) 1/8" .8 (.4) 5-1/4 (132) 1-1/2 (37)

51732 50,000 .1 (75) 64 8 SCFM (227 LPM) 3 mm .8 (.4) 5-1/4 (132) 1-1/2 (37)

51733 60,000 .1 (75) 69 8 SCFM (227 LPM) 3 mm .8 (.4) 5-1/4 (132) 1-1/2 (37)

51750 60,000 .1 (75) 69 8 SCFM (227 LPM) 1/8" .8 (.4) 6 (152) 1-1/2 (37)

51753 50,000 .1 (75) 69 8 SCFM (227 LPM) 1/8" .8 (.4) 6 (152) 1-1/2 (37)

51756 35,000 .1 (75) 69 8 SCFM (227 LPM) 1/8" .8 (.4) 6 (152) 1-1/2 (37)

DYNABRADE, INC. www.dynabrade.com

8989 Sheridan Drive •Clarence, NY 14031-1490 •Phone: (716) 631-0100 •Fax: 716-631-2073 •International Fax: 716-631-2524

© DYNABRADE, INC., 2010 PD10.37_rev.2_03/14

1. American National Standards

Institute – ANSI

25 West 43rd Street

Fourth Floor

New York, NY 10036

Tel: 1 (212) 642-4900

3. Power Tool Institute, Inc.

P.O. Box 818

Yachata, Oregon 97498-0818

Tel: 1 (503) 547-3185

4. European Committee for

Standardization

Rue de Stassart 36

B - 1050 Brussels, Belgium

2. Government Printing Office – GPO

Superintendent of Documents

Attn. New Orders

P.O. Box 371954

Pittsburgh, PA 15250-7954

Tel: 1 (202) 512-1803

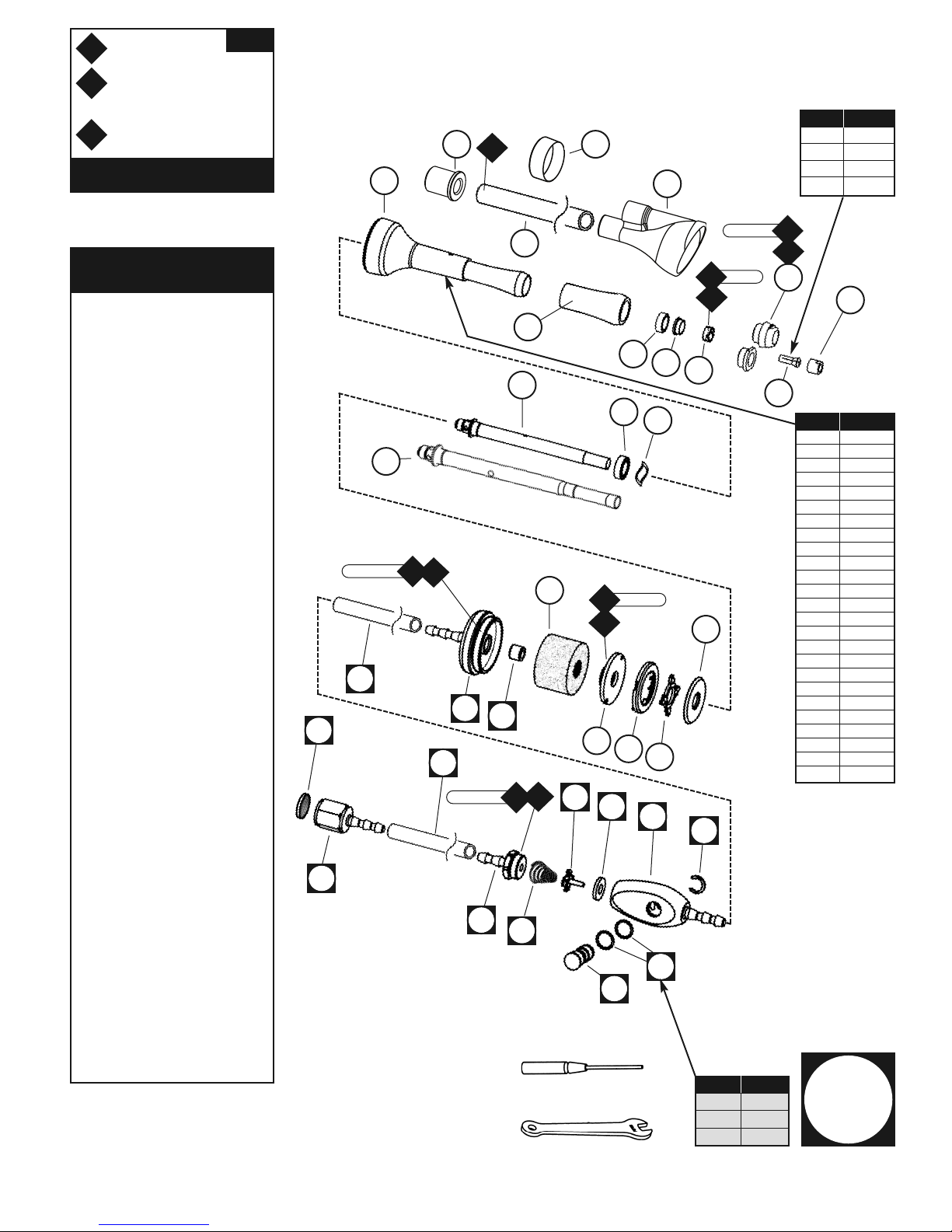

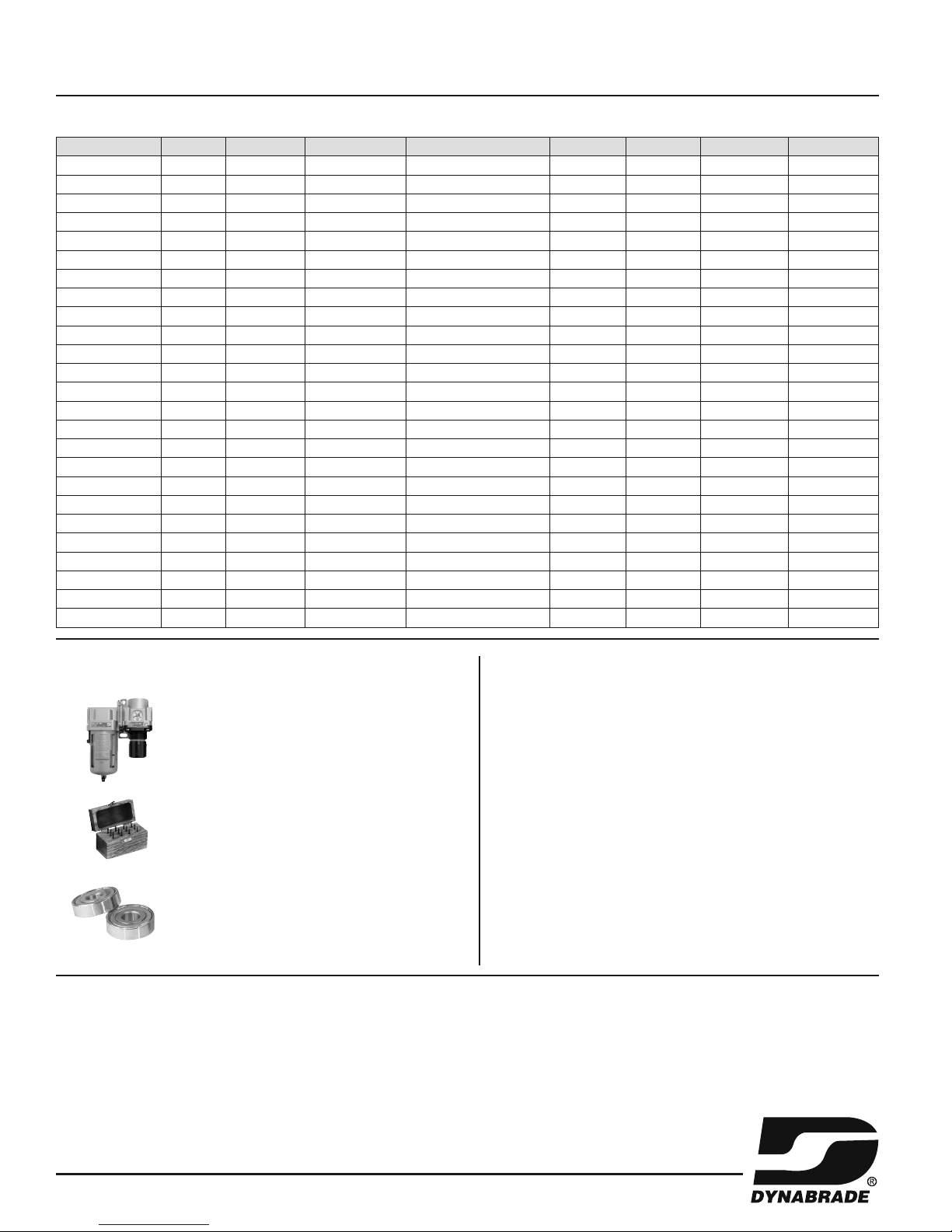

OPTIONAL ACCESSORIES SPECIAL REPAIR TOOLS

MACHINE SPECIFICATIONS

REFERENCE CONTACT INFORMATION

LIFETIME WARRANTY

To validate Dynabrade Lifetime Warranty, you must register each tool at: www.dynabrade.com. Registration of each tool at website is required. Dynabrade

will not honor Lifetime Warranty on unregistered tools. Please view the entire Lifetime Warranty Policy at : www.dynabrade.com.

94999 – Air Bushing Tool

96406 – .18" Dia. Pilot Punch

96407 – Bearing Retainer Wrench

96408 – Top Plate Wrench

96418 – Bearing Press Tool

.623" O.D., .375" I.D.

96419 – Bearing Press Tool

.498" O.D., .315" I.D.

96479 – Extension Retainer Wrench

96483 – Sleeve Assembly Bullet

96486 – Collet Insert Removal Tool

96439 – Extension Collet Guard Wrench

Additional Specifications: Air Inlet Thread 1/4" NPT • Hose Size 1/4" (6 mm)

Sound Level is the pressure measurement outlined in ISO regulation ISO-15744

P/N 93351

• 1/8" Carbide Burr Kit, includes 12 burrs for

grinding, deburring, and finishing.

P/N 51685 Ceramic Bearing (Front)

P/N 51686 Ceramic Bearing (Rear)

• Provide better performance and durability in

the face of the following environmental factors:

high speeds, dirt, corrosion and extreme

temperatures.

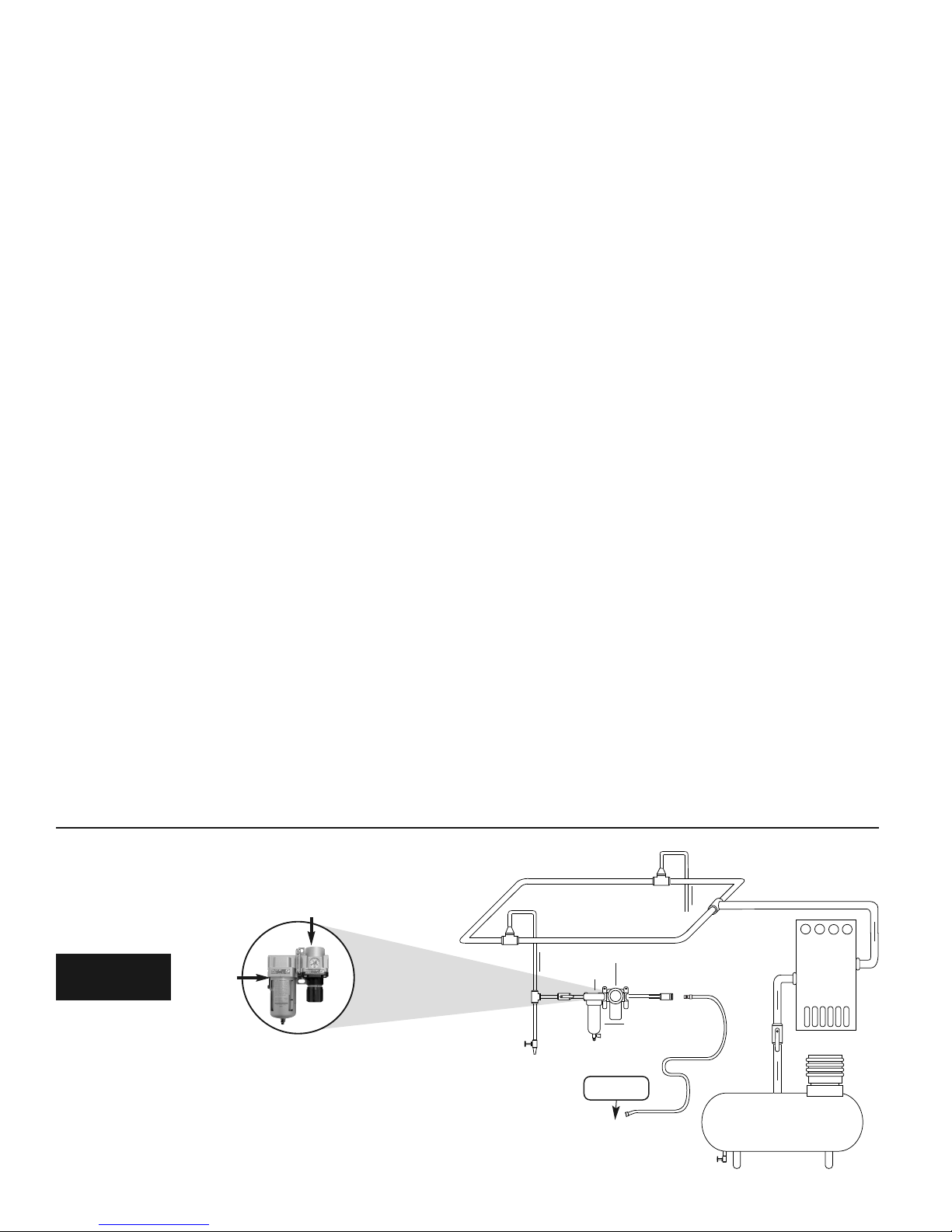

Model 10677: Up to 55 SCFM @ 145 PSIG

1/2" NPT Female ports, includes (2)

3/8" NPT reducers.

• Filter-Regulator, provides accurate air pressure

regulation and two stage filtration of

water/contaminates.