Page 2 of 32

Ta le of Figures .................................................................................................................. 3

Section 1: A out This Manual ............................................................................................ 4

Section 1: A out This Manual ............................................................................................ 4

Who Should Attempt this Project? ................................................................................. 4

Tools You’ll Need........................................................................................................... 4

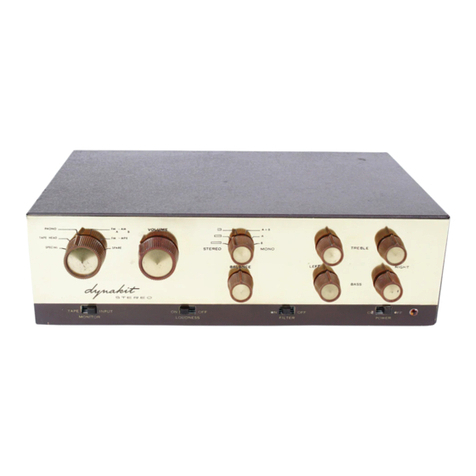

Project Overview ............................................................................................................ 5

Important Safety Notes ................................................................................................... 5

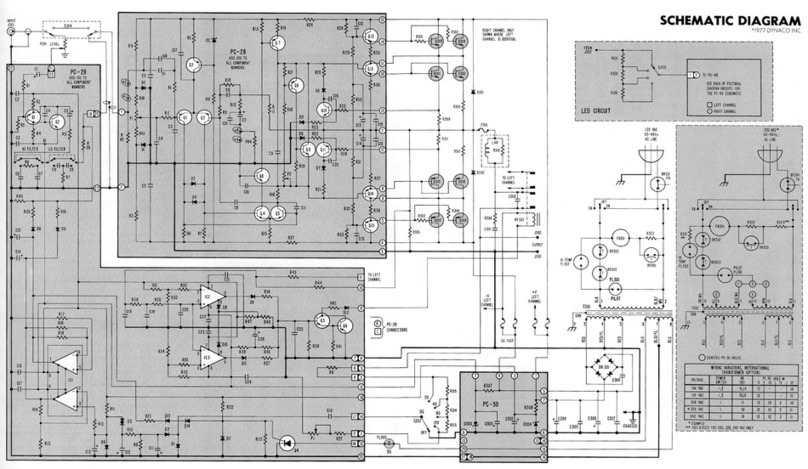

Section 2: Checking the Stereo 120 Power Supply ............................................................ 6

Opening the Amplifier .................................................................................................... 6

Check the Power Supply Voltages.................................................................................. 6

Section 3: Saving the Stuff that Should Be Saved.............................................................. 7

Cutting the wires on the old amplifier modules.............................................................. 7

Removing the LEFT channel module......................................................................... 7

Removing the RIGHT channel module ...................................................................... 8

Removing C7 RIGHT ............................................................................................... 11

Removing C7 LEFT.................................................................................................. 11

Removing the Output Zo el Networks ..................................................................... 11

Section 4: Trou leshooting the Stereo 120 Power Supply ............................................... 13

Prepare and Connect the Test Load .............................................................................. 13

Test the Power Supply .................................................................................................. 13

Just In Case – Trou le Shooting ................................................................................... 14

The Voltage is Much More than 78 volts ..................................................................... 14

The Voltage is Much Less than 66 volts....................................................................... 14

There’s No Voltage at All............................................................................................. 14

Section 5: Building the Updated Circuit Boards............................................................... 15

Install the Resistors ....................................................................................................... 15

Install the Small Capacitors and the Diodes ................................................................. 17

Last Capacitors and the Transistors .............................................................................. 18

Winding the Output Inductor ........................................................................................ 18

Solder the LM3886 into the Board ............................................................................... 19

Final Inspection of the Circuit Board............................................................................ 22

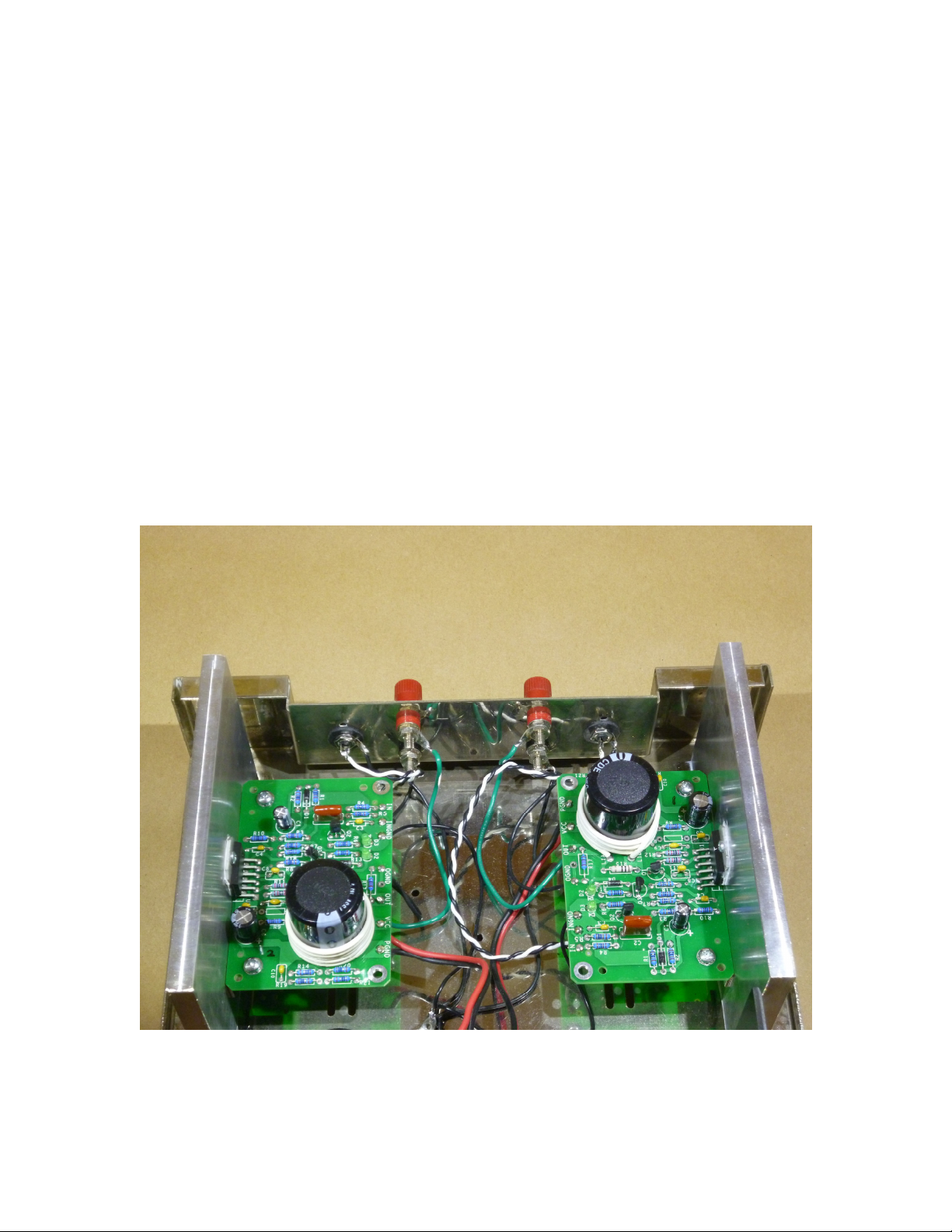

Mounting the Updated Amplifier Board to the Super Heat Sink.................................. 23

Section 6: Wiring In the Updated Amplifier Modules...................................................... 25

Building and Installing the Power Wiring Harness ...................................................... 25

Building and Installing the Ground Wiring Harness .................................................... 26

Wiring the Inputs .......................................................................................................... 27

Wiring the Outputs........................................................................................................ 27

Connecting the Left Channel Amplifier Module .......................................................... 27

Connecting the Right Channel Amplifier Module........................................................ 28

Making the Speaker Binding Posts User Friendly........................................................ 29

Section 7: Testing the Completed Amplifier .................................................................... 29

Test #1........................................................................................................................... 29

Test #2........................................................................................................................... 30

Test #3........................................................................................................................... 30

Test #4........................................................................................................................... 30

Resistor Color Code...................................................................................................... 32