6

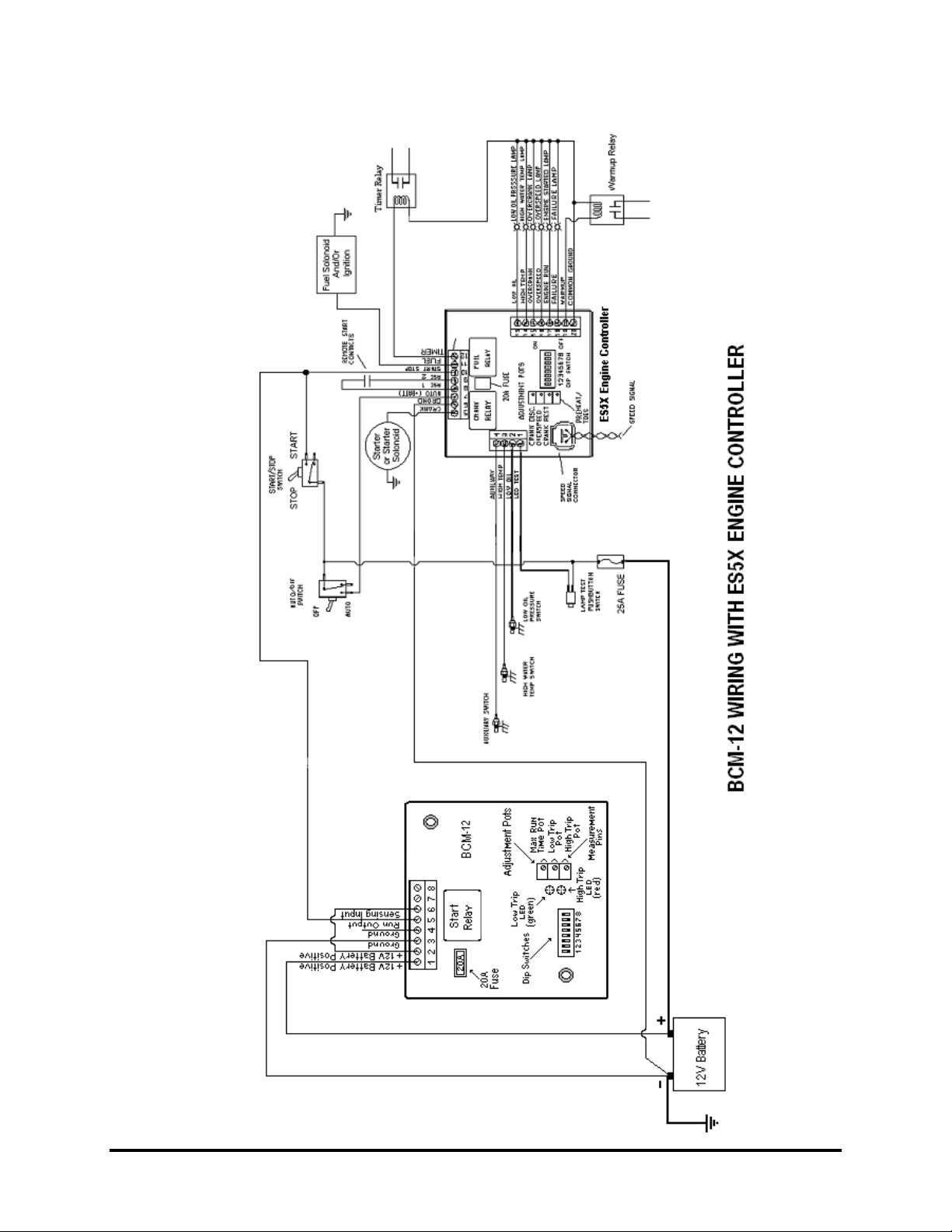

WIRING GUIDELINES

1. DO NOT use wire smaller than 18 AWG.

2. DO NOT short Run output to ground, as this will cause 20A fuse to blow, and may cause

damage to on board relay contacts.

3. Replace on board 20A fuse with similar type and rating (Replacement fuse to be Blade type

MINI FUSE rated 20 Amps maximum). Never bypass fuse with jumper, as this will not

protect unit in the event of a short circuit or overload condition.

4. DO NOT exceed the maximum rated current and voltage on the BCM output. Do not exceed

10 amps for Run output.

5. Do not reverse power supply connections to the BCM unit as this will result in permanent

damage to unit.

6. Installation of a diode is not required across Run output. An internal fast switching diode is

provided to protect the BCM output from inductive kick-back. However, diodes should be

placed across external slave relay contacts when used to actuate any inductive loads, such as

solenoids, to protect the contacts from damage caused by arcing. In addition to prolonging

the useful life of the relays, placing such diodes will enormously reduce generated electrical

noise.

7. DO NOT short potentiometer jumpers to ground, as this may result in damage to BCM unit.

These jumpers are located adjacent to the potentiometers on rear of unit, they provide a

method for simple and easy calibration of LOW, HIGH and RUN TIME set points.

8. There is a potentiometer, which is just below the potting, adjacent to the Run relay. DO NOT

attempt to adjust this pot. This pot has been calibrated at the factory and does not require

field adjustment. Adjusting this pot will greatly affect the sensing accuracy of the BCM unit.

9. Replace On board relay with similar type and rating. Some replacement types are as follows:

• Bosch Part # 0 332 207 307

• American Zettler Part # AZ977-1A-12D

• Aromat Part # CM1–R –12V

Operating & Installation Manual for Battery Charge Monitor (BCM)