Wiring and Setup 4

© 2019 DynaGen Technologies IncTOUGH Series Manual

2Wiring and Setup

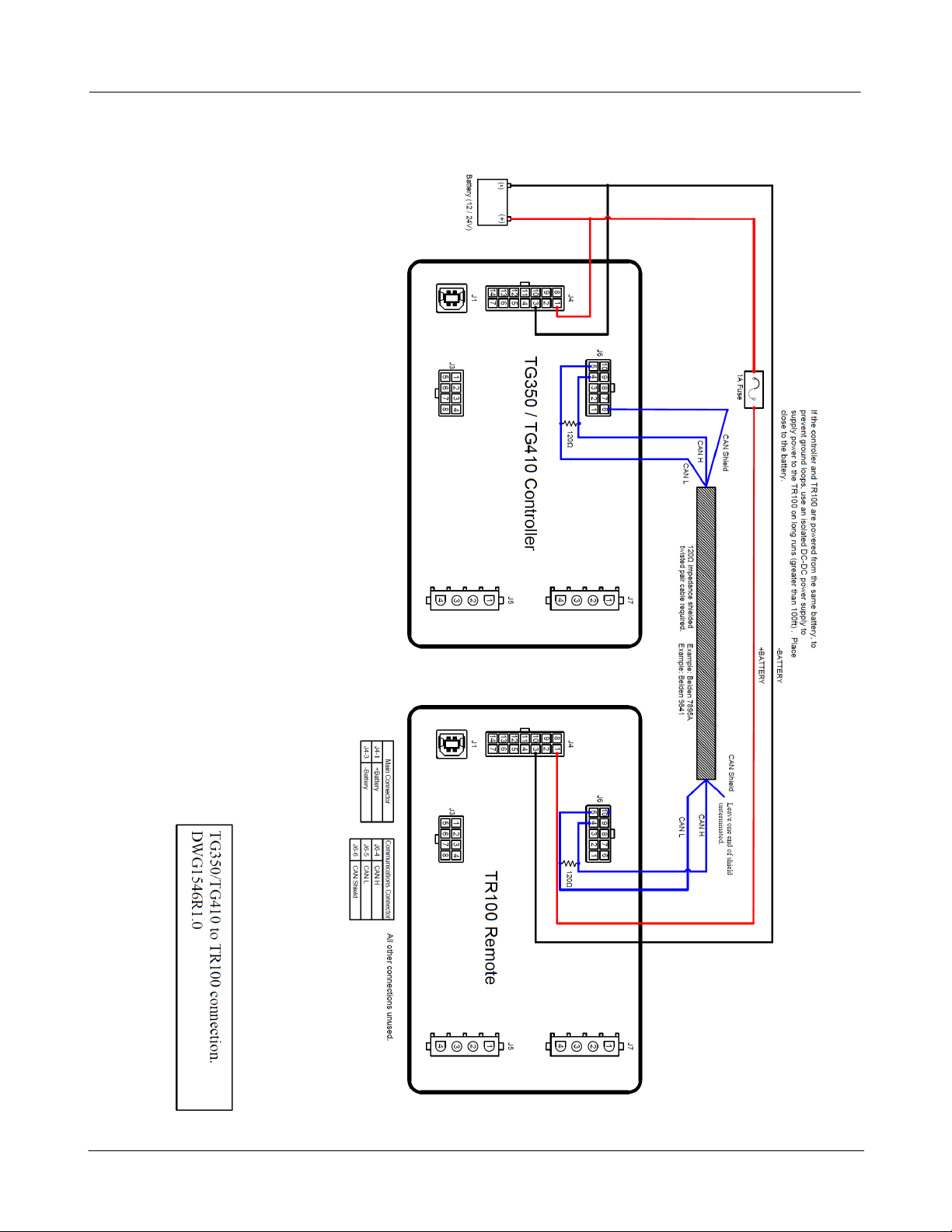

Please follow the below guidelines w hen installing the remote panel.

Wiring

1. The maximum J1939 (CAN) cable distance is 40m (131.2ft). Tw isted pair or shielded tw isted pair cable must be used.

See J1939 standards J1939-11 for tw isted shield pair requirements or J1939-15 for tw isted pair (unshielded)

requirements. In brief, the cable must have a characteristic impedance of 120Ohms terminated at each end by 120Ohm

resistors. Note: cable impedance is not the same as the resistance of the cable.

2. The remote panel must be provided w ith pow er and ground connections.

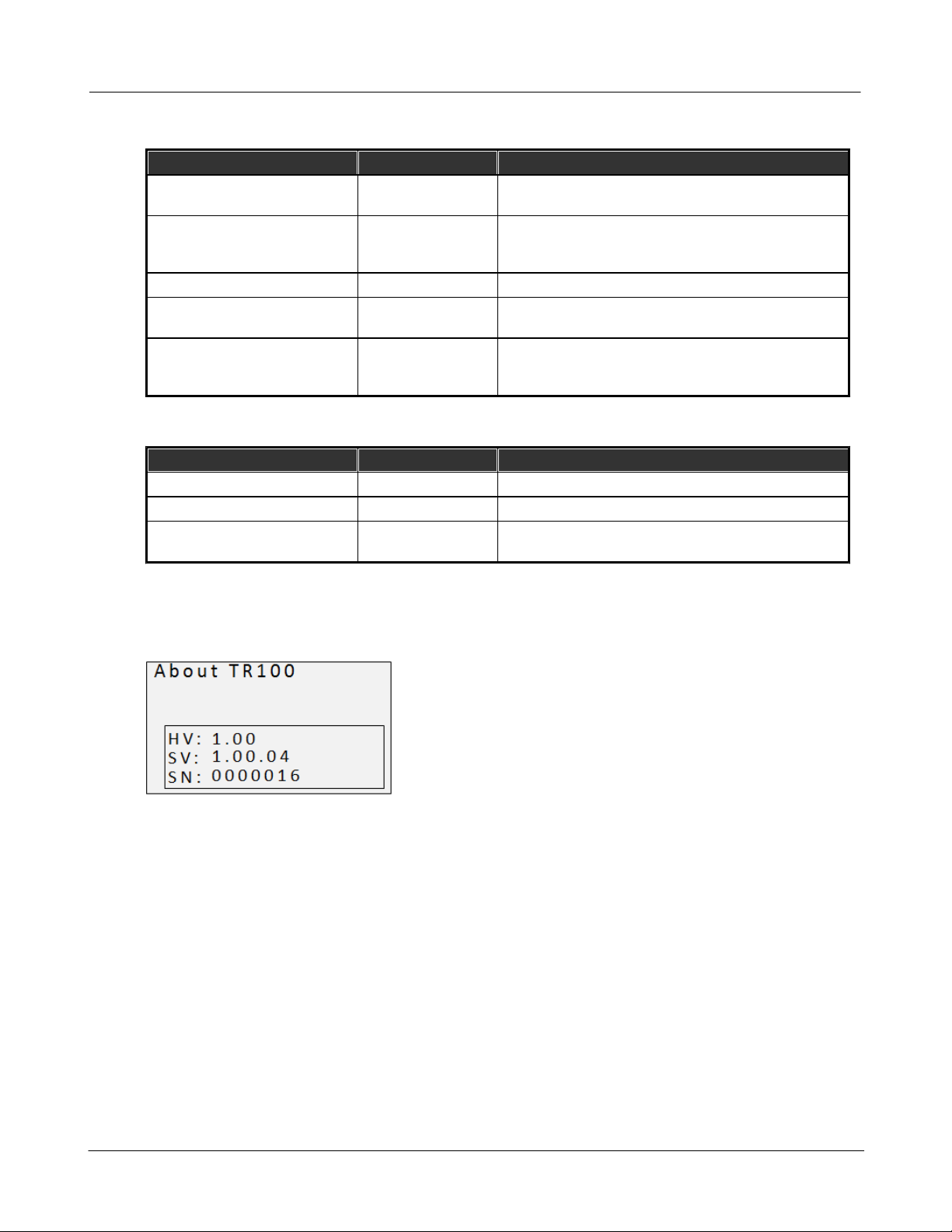

TR100-E Setup

1. Dow nload the TR100-E firmw are from w w w .dynagen.com/support and unzip it to the desktop.

2. Using RapidCore program this firmw are into a TE350 or TE410 to convert it into a TR100-E.

Local TE350 / TE410 Setup

The remote needs access to certain parameters over the CAN J1939 bus. To do this follow these steps:

1. Using RapidCore read the settings from the local controller. A new settings tab w ill open. Go to that settings tab.

2. Under Communications > J1939 Bus > Broadcast Over J1939:

a. In the case of a mechanical engine these must be broadcasted by the local controller. Enable Engine Speed, Engine

Temperature, Oil Pressure, and Engine Hours.

b. In the case of an electronic engine some parameters are already broadcasted by the ECM and should not be sent by

the controller. Disable Engine Speed, Engine Temperature, Oil Pressure, or Engine Hours as these parameters are

send by the engine ECM. They should be hidden by default by RapidCore.

3. It is recommended to set "DTC Warning Broadcast Mode" to "Multiple Warning".

4. Enable Battery Voltage.

5. Enable AC Sensing and Fuel Level if applicable to your application.