IMPORTANT - PLEASE READ BEFORE PROCEEDING!

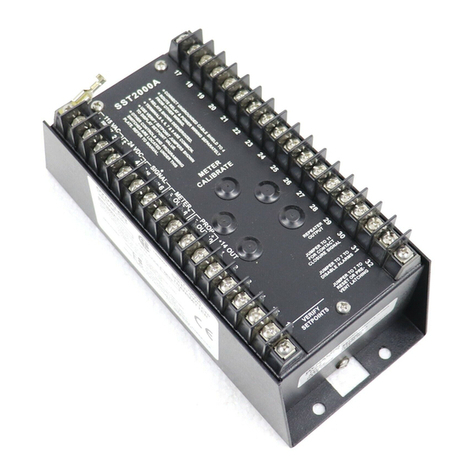

The Dynalco SST2000 series speed switch / transmitter is designed for reliable and rugged operation. This

product has been designed and tested to meet the demands required in many industrial and hazardous

locations meeting critical CSA standards. Performance of this product is directly related to the quality of the

installation and knowledge of the user in operating and maintaining the instrument. To ensure continued

operation to the design specifications, personnel should read this manual thoroughly before proceeding with

installation, operation and maintenance of this instrument. If this product is used in a manner not specified by

Dynalco, the protection provided by it against hazards may be impaired.

Dynalco® is a Barksdale® brand.

WARNING

Failure to follow proper instructions may cause any one of the following situations to occur: Loss of life;

personal injury; property damage; damage to this instrument; and warranty invalidation.

For clarification of instructions in this manual or assistance with your application, contact Dynalco as

below:

Tech Support: Technical-dynalco-support@barksdale.com or 1-866-227-8528

Customer Care: Sales-Dynalco@barksdale.com or 1-800-835-1060

Or by mail:

Barksdale Inc.

Barksdale® and Dynalco® Products

3211 Fruitland Ave

Los Angeles, CA 90058

Additional manuals and CSA certificates are available at www.dynalco.com

Follow all warnings, cautions, and instructions marked on and supplied with the product.

Use only qualified personnel to install, operate, program and maintain the product.

Educate your personnel in the proper installation, operation, and maintenance of the product.

Install equipment as specified in the installation section of this manual. Follow appropriate local and

national codes. Only connect the product to power sources and end devices specified in this manual.

Any repair is only to be performed by Dynalco using factory documented components. Tampering or

unauthorized substitution of parts and procedures can affect the performance and cause unsafe

operation of your process.

All equipment doors must be closed and protective covers must be in place unless qualified personnel

are performing maintenance.

Trademarks

SST-2000A/H, SST-2200A and SST-2400H are trademarks of Dynalco.

(c) Copyright 2016, Barksdale, Inc.

Specifications and information herein are subject to change without notice. Dynalco reserves the right to make changes to the equipment described herein to improve

function or design. Although the information contained in this manual has been carefully reviewed and is believed to be reliable, Dynalco Controls does not assume any

liability for special, indirect, incidental, or consequential damages arising out of the application or use of the equipment described herein. Warranty is limited and cannot

exceed the price paid for the product upon which the warranty is based.